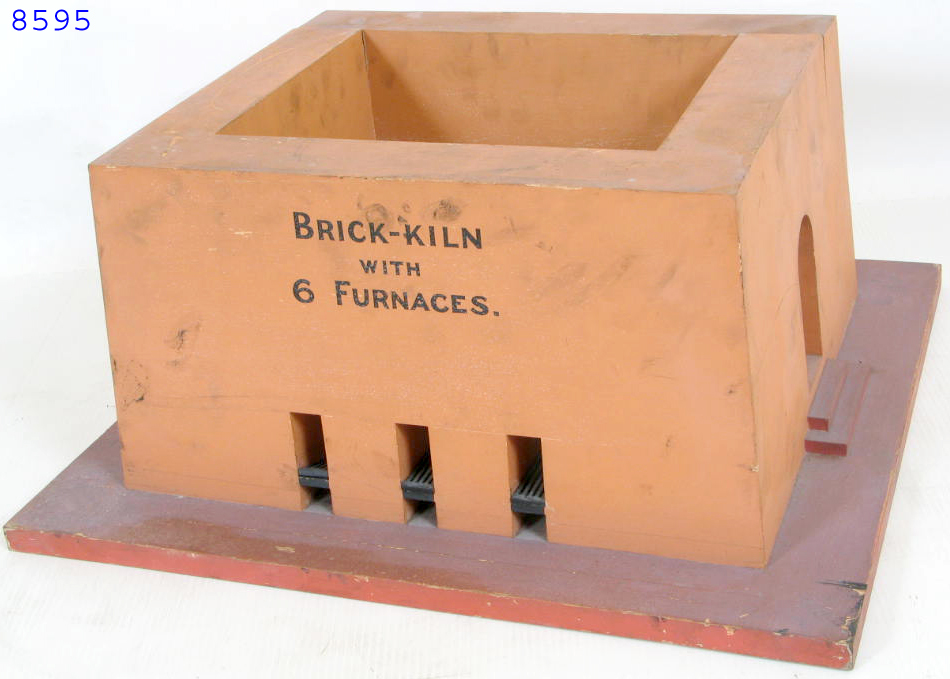

Model of Scotch brick kiln

Object No. 8595

This is a model of an open or Scotch brick kiln used for firing air-dried bricks during the 1800s. It comprises a large rectangular chamber open at the top with three charging doors or fire holes along each side opposite one another. The bricks to be burnt were stacked in the kiln in such a way that flues (ducts) were left connecting the fire holes. A layer of old burnt bricks was then spread over the top, the ends of the kiln were bricked up and roughly plastered over with clay and the fires were lit in the fire holes. The fire then passed between and around the bricks from bottom to top (updraft). The kiln worked to a cycle which involved filling the kiln, firing it, allowing it to cool then emptying it. When the burning process was completed, the kiln was allowed to cool and the bricks taken out. With this method of manufacture, the shade of the fired bricks varied a great deal in colour. Those nearest to the fire holes were the darkest and the hardest. Because of the degradation of stone from heavy pollution in British cities during the Industrial Revolution, bricks were found to be much more durable to the smog and became the building material of the age. They were used to build workers' housing in the expanding cities, mills, sewers, canal tunnels and railway infrastructure. This type of kiln was commonly used in Britain and as late as 1900 the great majority of bricks produced there were made in a kiln like this model. However, intermittent kilns were replaced by more efficient Hoffman circular continuous kilns which had been patented in Germany in 1858 by Friedrich Hoffmann. These involved a series of connected chambers in a circular or rectangular pattern which allowed the fire to be led progressively around the whole circuit. Burnt bricks were taken out and green bricks placed in the chambers furthest away from the fire. Kilns like these used less fuel and were more efficient of time and resources. Because of the enormous cost of transporting bricks within Australia, due to the distance and lack of good roads, country brickworks sprang up in most significant towns during the 1800s to meet local building demands. In 1884 the Museum spent the then substantial sum of 500 pounds on models made by the German manufacturer Carl Schroder of Darmstadt. This included 80 model furnaces demonstrating different methods of processing raw materials. This model kiln was one of them and it was used for displays at the Museum from 1884 onwards, around the same time as brickmaking throughout New South Wales was underway. Hudson, Kenneth, 'Building Materials', Longman Group Ltd, London, 1972, pp.32-33. Margaret Simpson, Curator January 2016

Loading...

Summary

Object Statement

Model of a scotch brick kiln, intermittent updraft type, with 6 charging doors (fire holes), supplied in 1884 to the Technological Museum, Ultimo, New South Wales, Australia, by Carl Schroder, Darmstadt, Germany

Physical Description

Scotch brick kiln model, intermittent updraft type, with 6 charging doors (fire holes), supplied in 1884 to the Technological Museum, Ultimo, New South Wales, Australia, by Carl Schroder, Darmstadt, Germany

DIMENSIONS

Height

270 mm

Width

570 mm

Depth

510 mm

HISTORY

Notes

In 1884 the Museum spent the then substantial sum of £500 on models made by the German manufacturer Carl Schroder of Darmstadt. This included 80 model furnaces demonstrating different methods of processing raw materials. This one is a model of a furnace or kiln for making bricks. The kiln model was used for displays at the Museum from the 1880s onwards.

SOURCE

Credit Line

Purchased 1884

Acquisition Date

29 December 1884

Copyright for the above image is held by the Powerhouse and may be subject to third-party copyright restrictions. Please submit an Image Licensing Enquiry for information regarding reproduction, copyright and fees. Text is released under Attribution-Non Commercial-No Derivative licence.

Image Licensing Enquiry

Object Enquiry