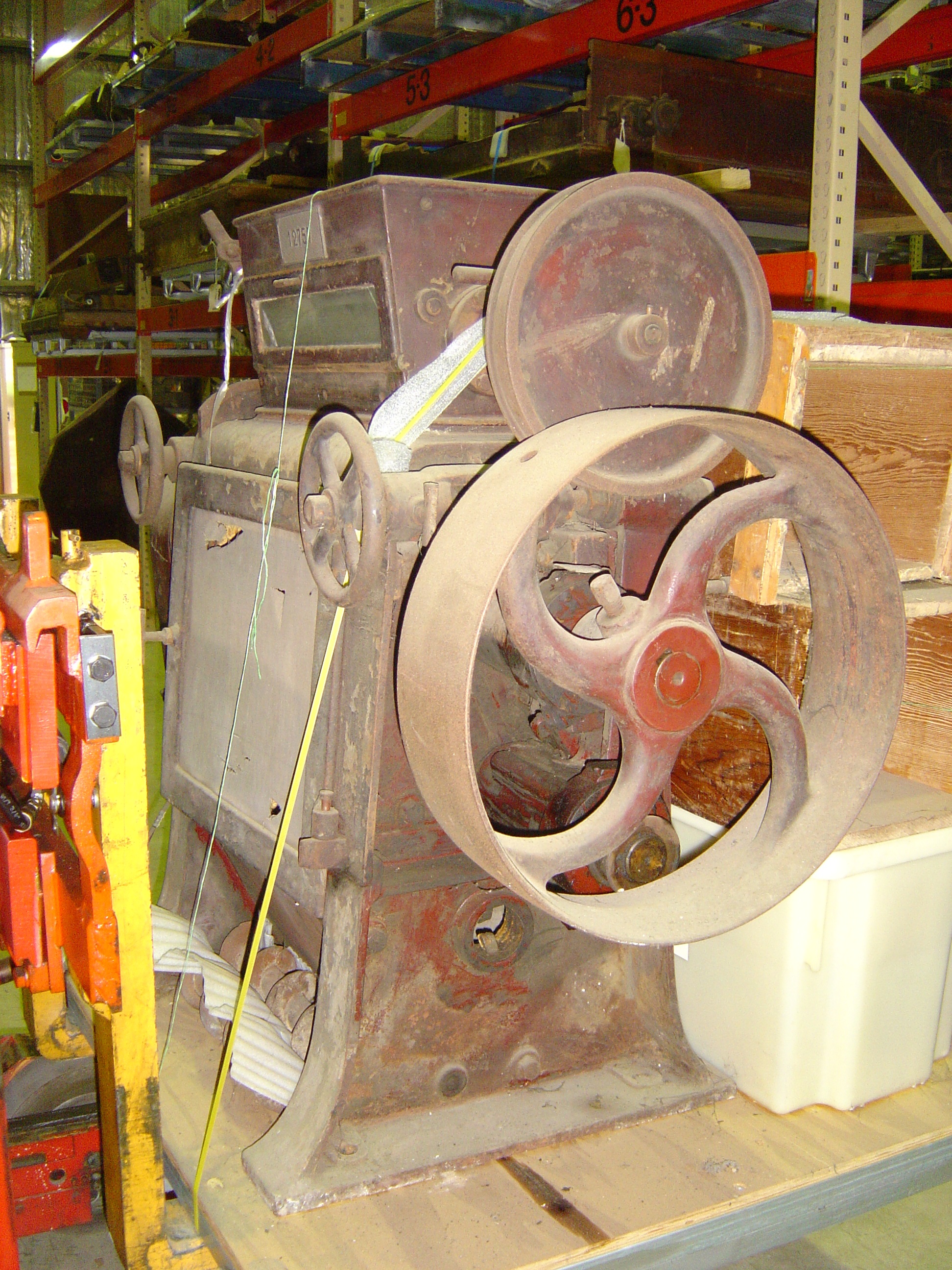

Robinson's flour mill equipment from McIntyre's mill, Hamilton, NSW

Object No. 85/548

This is vertical roller mill equipment used for grinding grain into flour in a roller flour mill. It was made in England between 1890 and 1900 by Thomas Robinson and Son Ltd of the Railway Works, Rochdale in Lancashire. Robinsons supplied many of their roller mills to flour mills around New South Wales. This particular roller mill machinery is significant because it features vertical rather than horizontal steel rolls. The roller mill was used at McIntyre's Hamilton Flour Mills in Hamilton, a suburb of Newcastle, New South Wales, operated as C.S. McIntyre Pty Ltd by Charles Shelly McIntyre (1877-1966) from 1900. Flour mills have been very important in Australia since colonial times with the early establishment of government-owned mills. Where-ever cereal farming occurred a flour mill was never far away with the spread of them really taking off from the 1850s onwards. The expansion of the railways significantly affected the siting and marketing of these mills. Early flour mills in Australia were powered by man, animal, wind, water and later steam. The grinding technology used was between the flat surfaces of horizontally-placed millstones. These grindstones had the disadvantage that their friction heated the grain which impaired the gluten of the flour; they crushed the bran with the grain; and required regular and expensive maintenance. Roller mills were invented in Hungary by Jacob Suizberger from Switzerland in 1834. In the early 1860s Friedrich Wegman introduced porcelain rollers for grinding flour which gave a better colour to it. Porcelain rollers were displayed at the Sydney International Exhibition of 1879 but the best were found to be grooved steel break rolls running at different speeds which were able to 'peel' the wheat kernel. Smooth steel and porcelain were then used for size reduction rolls. Rollers were mounted side-by-side or one above the other, but from about 1910, the axes were in an inclined plane. Gradually the rollers took over from grindstones, with rollers initially working alongside stones in the same mill. White flour milled with rollers caused a great sensation amongst consumers and mills around the country began to convert their machinery at great cost. Roller mills gave millers better control of their product and an incentive to buy better grades of wheat. The flour they produced was finer and less contaminated with by-products. A new age of milling machinery had arrived and by 1890 roller mill technology had become widely accepted in Australia. This involved installing the roller equipment together with cleaning, grading and dressing machines. Roller flour mills were initially steam driven but later converted to electric power. These types of mills were large structures with high capacity grain storage silos and grinding machinery on several floors. The process of roller mills involved the grain being passed through a number of spirally-fluted rolls in sequences to break open the grain. The resulting stock is sifted and graded and finally fed through plain rolls to produce the desired type of flour. The stock was taken from machine to machine via enclosed conveyors and finally bagged ready for market. Many small country flour mills using millstones could not compete with the large roller mills and milling was relegated to large country towns and cities. Birmingham, Judy, Ian Jack and Denis Jeans, 'Industrial Archaeology in Australia: Rural Industry', Heinemann Publishers, Australia, 1983. Jones, William, 'Dictionary of Industrial Archaeology', Sutton Publishing Ltd, Stroud, Gloucestershire, England, 2006 'Technology in Australia 1788-1988', Australian Academy of Technological Sciences, Melbourne, 1988. Phillip Simpson, 'Historical Guide to New South Wales', Australian Scholarly Publishing Pty Ltd, North Melbourne, Vic., 2020. Margaret Simpson, Curator November 2015

Loading...

Summary

Object Statement

Flour mill equipment, vertical roller, No. 12757, made by Thomas Robinson and Son Ltd, Railway Works, Rochdale, Lancashire, England, 1890-1910, used at C.S. McIntyre's Hamilton Flour Mills, Hamilton, Newcastle, New South Wales, Australia

Physical Description

A timber and steel framed roller mill used to grind wheat and other grains into flour. The two steel rolls are arranged vertically.

PRODUCTION

Notes

Thomas Robinson and Son were established in Rochdale, Lancashire, in 1838 as timber merchants, joiners and carpenters. In 1882 that decided that flour milling machinery was an ideal opportunity to expand their business so with the their existing pattern shops, foundries, and fully-equipped fitting and erection shops they were at an advantage to add flour milling equipment to their list of products. In 1884 Thomas Robinson and Sons announced that they could equip a complete flour mill with their own make of machinery.

HISTORY

Notes

Milling began at the Hamilton Flour Mills in 1900 under Peter McIntosh and Charles Shelley McIntyre. Hamilton Mill was upgraded in 1936 and 1952, sold in 1982 to Allied Mills and then later sold to Fielders Pty Ltd. This roller mill machine was thought to have been removed in 1976. The mill buildings were damaged during an earthquake in 1989 and the mill's silos were demolished. It was subsequently closed and reused. This roller mill went into the Willow Vale Milling collection at Willow Vale Mill, Laggan, New South Wales, and was acquired by the Museum in 1985.

SOURCE

Credit Line

Purchased 1985

Acquisition Date

7 May 1985

Copyright for the above image is held by the Powerhouse and may be subject to third-party copyright restrictions. Please submit an Image Licensing Enquiry for information regarding reproduction, copyright and fees. Text is released under Attribution-Non Commercial-No Derivative licence.

Image Licensing Enquiry

Object Enquiry