'Bung Plug' or 'Bum Dum' small stock rectum sealing device by Bestaxx and Vert

Object No. 2013/115/1

The Australian standard for the hygienic production of meat for human consumption requires 'The discharge of any material from the esophagus, stomach, intestines, rectum, gall bladder, urinary bladder and uterus is prevented.' During procedures, if faecal matter is discharged and contaminates carcasses, the material must be completely trimmed off. Thus the trimming of contaminated carcasses can be greatly reduced if the rectum is sealed securely. The 'Bung Plug' or 'Bum Dum' prevents leakage of faecal material, for improved carcass hygiene, thus reducing the number of carcasses that have to be retained and trimmed. Developed by Bestaxx and Vert Design it also makes the task of releasing the rectum from the pelvic channel easier and improves the ergonomics of dressing procedures. The Bung Plug is a remarkable design story. The traditional approach to this problem meant that a high percentage of lambs were wasted and the procedure was very inefficient. The Bung Plug represents the application of professional industrial design in an industry that has not traditionally utilised designers. The result has revolutionised the process and prevents waste. It is an example of excellence in Australian design and received an Australian International Design Award - Best in Category (Medical and Scientific) and the Powerhouse Museum Design Award in 2012. Angelique Hutchison Curator August 2013

Loading...

Summary

Object Statement

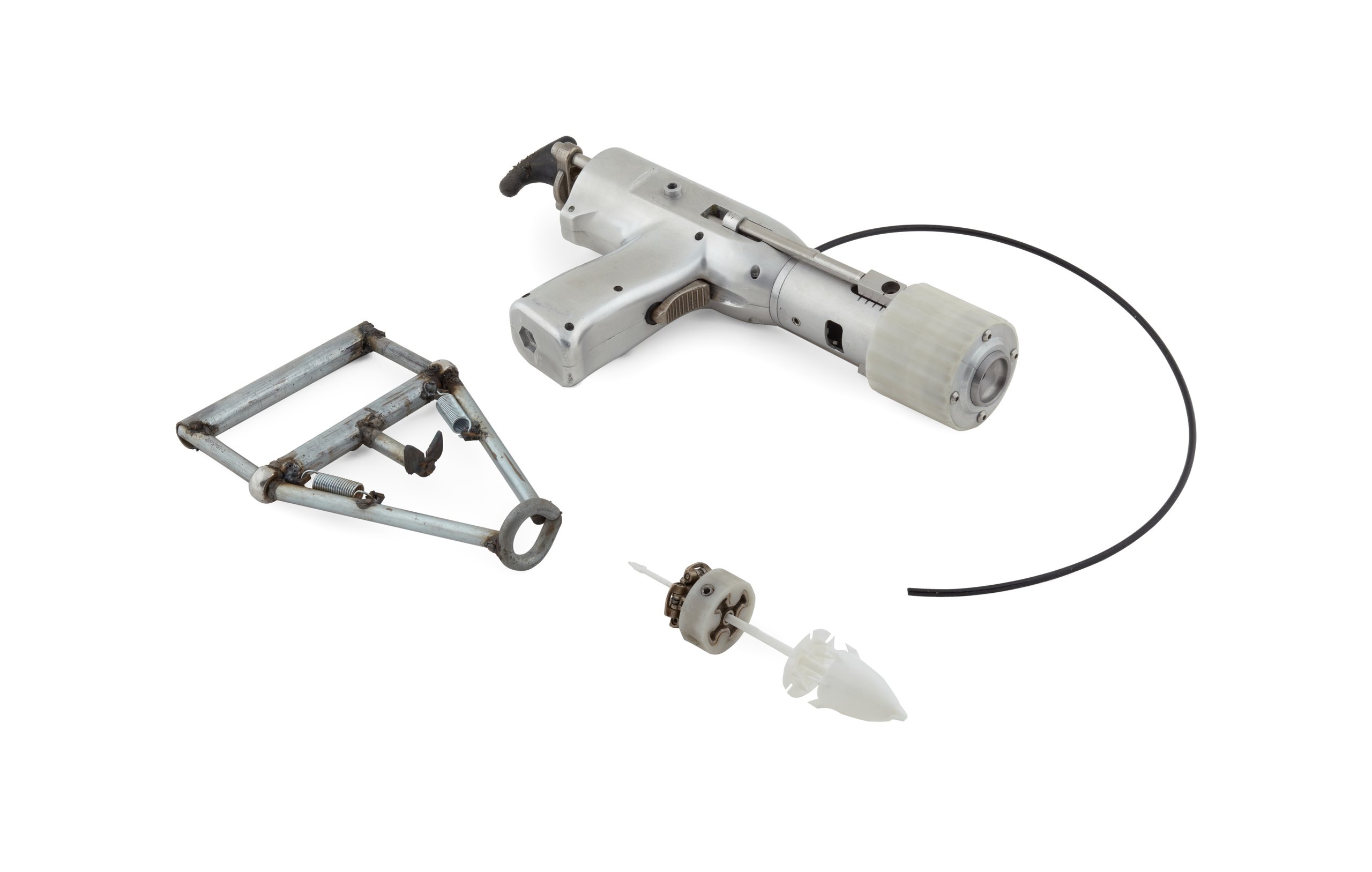

Small stock rectum sealing device, 'Bung Plug' or 'Bum Dum', prototype applicator gun, prototype hand applicator, latch mechanism, prototype plugs (3), final plastic plugs (4), metal / plastic, designed and made by Vert Design / Bestaxx Pty Ltd, Sydney, New South Wales, Australia, 2009-2012

Physical Description

Small stock processing evisceration plug with prototype pneumatic insertion gun or applicator air tool. Seals the rectum of small stock from the point of application to evisceration. The Bung Plug can be observed on the viscera table attached to the large intestine and creates and additional process monitoring inspection point for processors. There is an additional prototype of hand applicator. There are three (3) prototype plastic plugs and four (4) of the the final plug design. One of the four final plugs has the latch mechanism mounted on it.

PRODUCTION

Notes

Co-invented by Andrew Simpson at Vert Design and Colin Plant at Bestaxx, Sydney, NSW, Australia, 2009-2012. Made by Vert Design and Bestaxx, 2009-2012. The Bum Dum or Bung Plug seals the rectum of small stock from the point of application to evisceration. It prevents leakage of faecal material, for improved carcass hygiene, thus reducing the number of carcasses that have to be retained and trimmed. The Bung Plug reduces faecal contamination and reduces costs by eliminating trimming of contaminated stock. The Bung Plug can be observed on the viscera table attached to the large intestine and creates and additional process monitoring inspection point for processors. It is suitable for pigs, goats, lambs and bobby calves. Manufactured from food grade materials that are compatible with all rendering plants and is safe for interaction with humans and animals.

HISTORY

Notes

This pneumatic insertion gun or applicator tool is one of the first working prototypes used to test the product in the field. This hand applicator is one of the first prototypes to test the mechanism for a separate hand applicator device which is used it the gun is unavailable or being repaired. These prototypes were used at Fletcher International abattoir in Dubbo, NSW, where all the testing was done during the development process. These objects were lent to the Powerhouse Museum for display in the 2012 Australian International Design Awards exhibition from July 2012 to July 2013 and subsequently donated to the collection. The Bung Plug received the Australian International Design Award - Best in Category (Medical and Scientific), and the Powerhouse Museum Design Award at the Australian International Design Awards ceremony on 20th July 2012. Since 1992 the Powerhouse Museum has recognised excellence in Australian product design with its own award as part of the annual Australian International Design Awards (AIDA) program The Museum displays the winning products in the AIDA gallery for one year. Some of these products and relevant design models and documents are added to the Museum's permanent collection of Australian industrial design. The Museum's selection is made from the AIDA finalists and the selection criteria include good design, innovation, sustainability and the significance of a product to Australia's material culture. There were 105 finalist recognised in the 2012 awards. The products receiving the Australian International Design Award were announced at a gala dinner and awards ceremony on 20th July at City Recital Hall Angel Place Sydney. At this ceremony the recipient of the Powerhouse Museum Design Award for 2012 was presented by the Director. The products receiving the Powerhouse Museum selection for display in the Australian International Design Awards exhibition were also be revealed at the ceremony. The Powerhouse Museum Design Award is presented to an Australian-designed product that has potential to make a significant improvement to the quality of the environment, health or wellbeing. It can also recognise a significant innovation to an industry.

SOURCE

Credit Line

Gift of Bestaxx and Vert Design, 2013

Acquisition Date

30 October 2013

Copyright for the above image is held by the Powerhouse and may be subject to third-party copyright restrictions. Please submit an Image Licensing Enquiry for information regarding reproduction, copyright and fees. Text is released under Attribution-Non Commercial-No Derivative licence.

Image Licensing Enquiry

Object Enquiry