Experimental polymer solar module

Object No. 2010/67/1

This module is part of a program whose long-term aim is to manufacture polymer solar modules, also called organic photovoltaic (OPV) modules, on large printing presses, greatly reducing the cost of solar electricity. Standard solar cells are about 200 micrometres thick and are made from silicon that is won from its oxide at high temperatures using charcoal as the reductant. In contrast, the active polymers in this module are made at low temperatures and deposited from solution in very thin layers. This leads to energy payback times of 3 to 4 months rather than 3 to 4 years. The aim of this part of the program is to test a range of techniques and parameters in order to create structures consisting of smooth, uniform, durable layers of polymers using methods that could be scaled up to roll-to-roll production on printing presses. This complements the research team's other aim, to improve the efficiency of its solar technology by making and testing a variety of small solar cells that incorporate novel polymers. The techniques used in making this module draw on experience in making polymer banknotes, a major Australian innovation whose development was led by Dr David Solomon. The banknote printing process has been commercialised, and banknotes marketed worldwide, by Securency, a partner in the polymer solar research. Another partner in the project is BlueScope Steel, which makes millions of square metres of roofing steel each year. Incorporating OPVs into roofs would benefit the company, building owners and the environment. The availability of building-integrated photovoltaics (BIPV) is growing, with a range of solar technologies being incorporated into building elements such as roofs and windows, and OPVs could accelerate this trend by reducing BIPV costs. Polymer photovoltaics have the following advantages over other solar modules: they are much lighter in weight; they can operate in low light conditions; they can be used on roofs that face any direction; their efficiency does not fall much over time; and they are less visually obtrusive. The disadvantages at present are their lower efficiency and shorter lifetime, and research groups around the world are working to address these problems. The module is also interesting because it incorporates two ideas for which chemists have received Nobel Prizes in recent years. These are the discovery of buckminsterfullerene by Kroto, Curl and Smalley in 1985, which won them the 1996 prize, and the development of conducting polymers by Alan Heeger, Alan MacDiarmid, and Hideki Shirakawa in the 1970s, which won them the 2000 prize. It also incorporates a semiconducting polymer; although these were known before the work of Heeger et al, this research led to better understanding of their electrical properties and hence helped later researchers design semiconductors for a range of applications.. Debbie Rudder, Curator, 2010 References M Jacoby, 'The power of plastic', Chemical & Engineering News, 23 August 2010, pp12-16. http://www.soci.org/Chemistry-and-Industry/CnI-Data/2009/21/Power-from-plastic http://www.plusplasticelectronics.com/Energy/BlueScope-Steel-interview.aspx

Loading...

Summary

Object Statement

Solar module, organic photovoltaic, PET / indium tin oxide / specialised polymers / silver, made by CSIRO Materials Science and Engineering, Clayton, Victoria, Australia, 2010

Physical Description

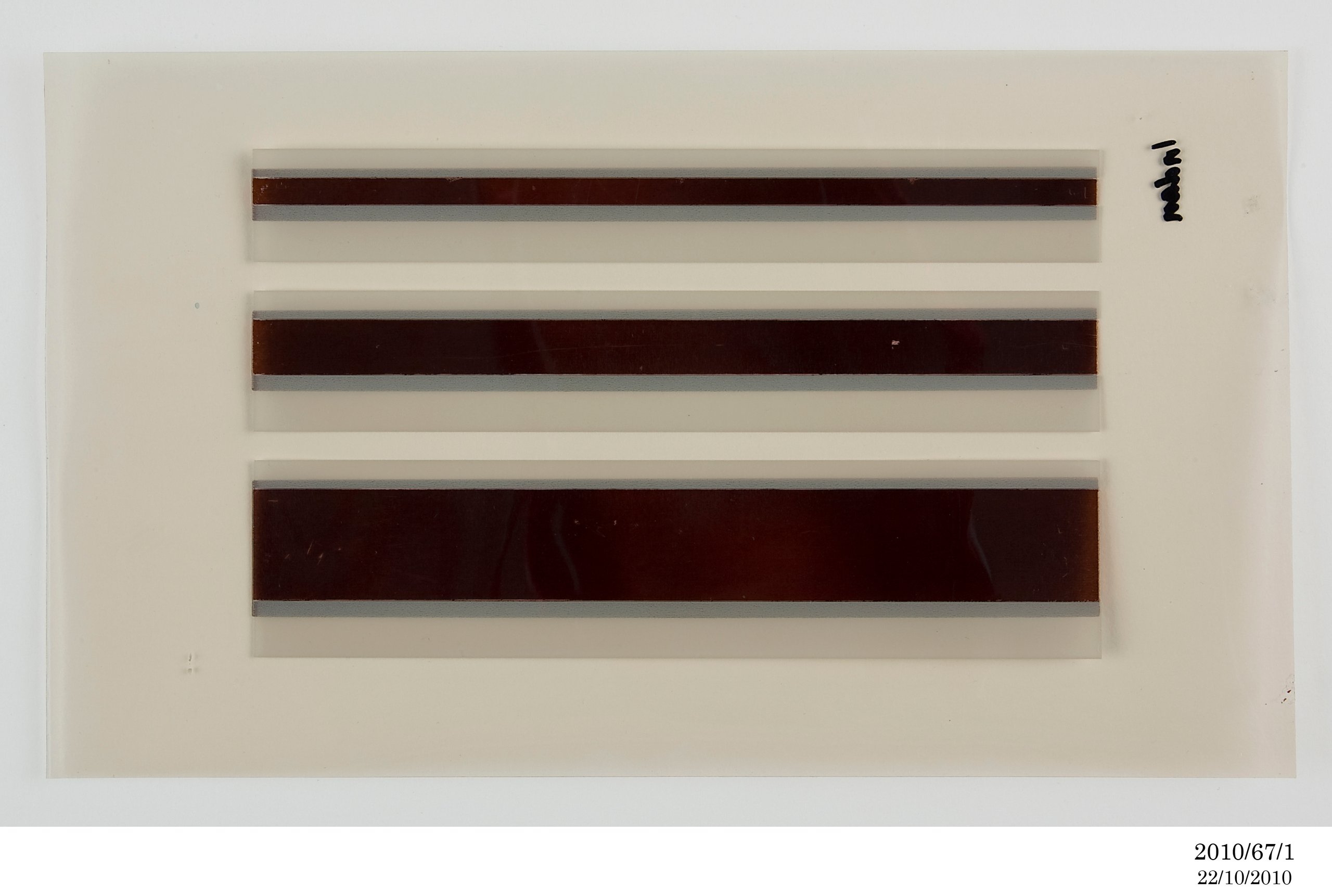

Solar module, organic photovoltaic, PET / indium tin oxide / specialised polymers / silver, made by CSIRO Materials Science and Engineering, Clayton, Victoria, Australia, 2010 Solar module with substrate comprising inert PET (polyethylene terephthalate) with a clear layer of indium tin oxide applied to it to form the anode. Specialised polymers have been printed onto the substrate in three red strips of varying width. Along each side of, and partially covering, each polymer strip is a strip of silver, which forms the cathode. A white insulating material (perhaps titanium dioxide) is deposited along the outer side of each silver strip. The red strips are built up in layers. The first layer is an insulating polymer with many tiny holes in it. The next two layers, which sit inside these holes, are: a conducting polymer; and a light-harvesting electron-donor red dye and a light-harvesting electron-donor semiconducting polymer intimately mixed with an electron-accepting buckminsterfullerene derivative, forming a bulk heterojunction material with large interfacial surface area. The top layer is a protective polymer coating. When light strikes the semiconducting polymer, electron-hole pairs form within it. The bulk heterojunction structure allows the electrons to move rapidly to the fullerene and then to the cathode, while the holes move to the anode. If the module is connected in a circuit, this movement of electrons and holes causes an electric current to flow.

DIMENSIONS

Width

128 mm

PRODUCTION

Notes

The module was made on 1 July 2010 at the CSIRO Material Science and Engineering laboratory in Clayton, a suburb of Melbourne, by a team led by Dr Gerry Wilson (Theme Leader, Flexible Electronics) and Dr Scott Watkins (Stream Leader, Organic Photovoltaics). A sheet of clear polyethylene terephthalate (PET) was coated with clear indium tin oxide (ITO), which forms the anode. A sheet of size 220 mm by 128 mm was cut from this, put through several cleaning steps, and dried in a stream of very pure nitrogen. Layers of material were added by Gravure printing in the following sequence and annealed on a hotplate after each step: Securency's proprietary insulating polymer; the conducting polymer poly(3,4-ethylenedioxythiophene) poly(styrenesulfonate), also known as PEDOT:PSS; a mixture of a light-harvesting red dye, the light-harvesting electron-donor semiconducting polymer poly(3-hexylthiophene), also known as P3HT, and the electron-accepting buckminsterfullerene derivative phenyl-C61-butyric acid methyl ester, also known as PCBM, in a solvent consisting of chlorobenzene and indan; and a protective InkTec coating ink. Strips of silver were then added by vacuum deposition to form the cathode. Professors Alan Heeger, Alan MacDiarmid, and Hideki Shirakawa were awarded the Nobel Prize for Chemistry in 2000 for their discovery and development of conducting polymers in the 1970s. Their work also improved understanding of the properties of semiconducting polymers and helped scientists design polymers with energy band-gaps appropriate for different tasks. Many groups of researchers are now developing solar technologies that incorporate conducting and semiconducting polymers. In 1996 Professors Harold Kroto, Robert Curl and Richard Smalley were awarded the Nobel Prize for Chemistry for their 1985 discovery of a previously unknown form of carbon, a stable sphere consisting of 60 atoms. They named this allotrope buckminsterfullerene because the shape resembled the geodesic dome popularised by Richard Buckminster Fuller; it also resembles a soccer ball made up of hexagons and pentagons, and its colloquial name is buckyball. Many applications have since been found for this and other fullerenes, and several groups working on organic photovoltaics are incorporating PCBM in their designs.

HISTORY

Notes

The module was donated to the Museum by the research team in 2010 for display in the updated Ecologic exhibition.

SOURCE

Credit Line

Gift of CSIRO Materials Science & Engineering, 2010

Acquisition Date

15 October 2010

Copyright for the above image is held by the Powerhouse and may be subject to third-party copyright restrictions. Please submit an Image Licensing Enquiry for information regarding reproduction, copyright and fees. Text is released under Attribution-Non Commercial-No Derivative licence.

Image Licensing Enquiry

Object Enquiry