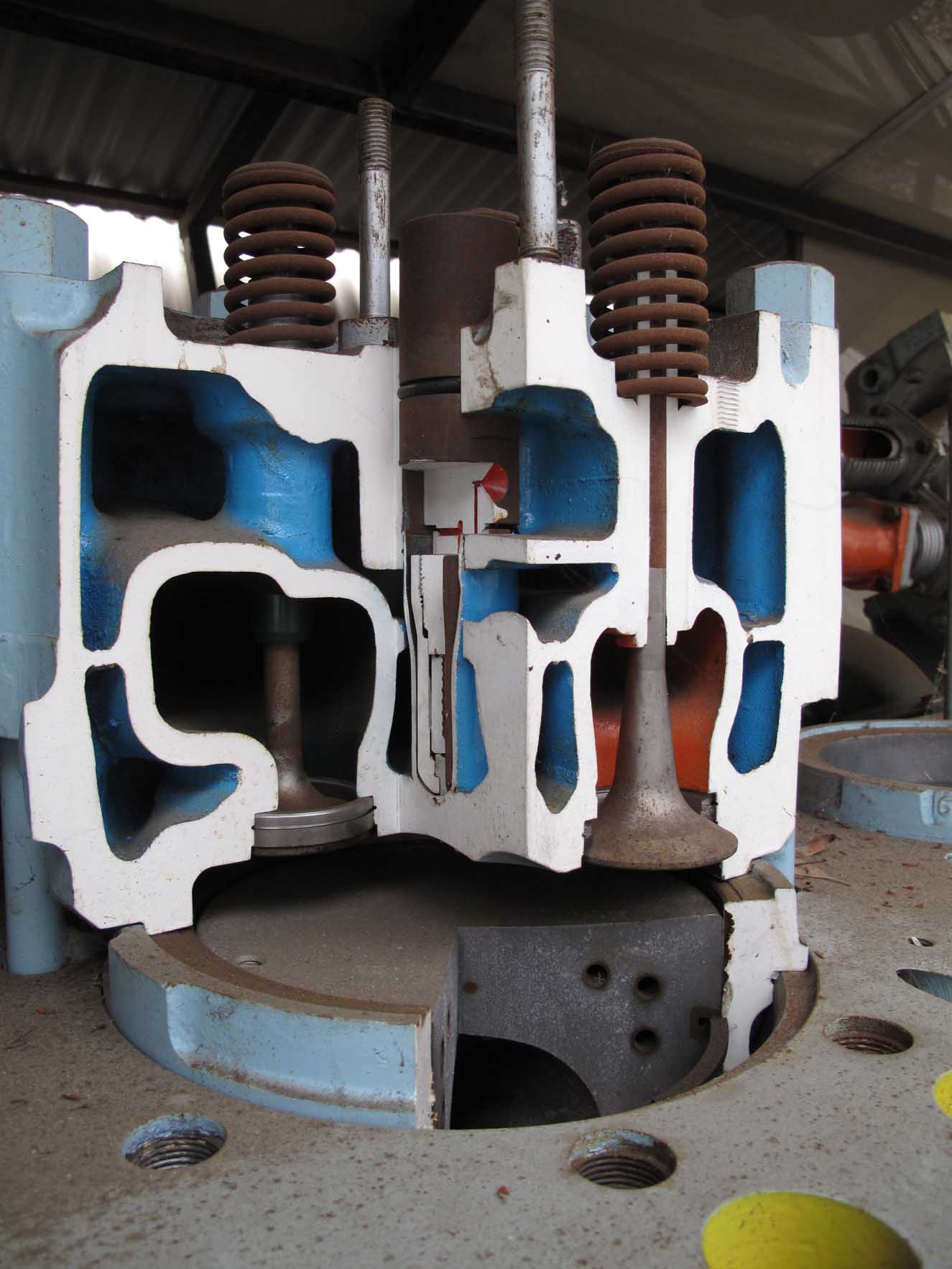

Sectioned diesel engine

Object No. 2011/58/1

This is an Alco 251C, 12-cylinder, 1950 hp diesel-electric locomotive engine made by Alco Products Inc., formerly the American Locomotive Company, of Schenectady, New York, USA, after 1965. The engine is representative of the motive power used in locomotives in New South Wales during in the change-over period from steam to diesel in the mid twentieth century. The engine comprised the power plant from a diesel-electric locomotive and can be described as a small mobile electric power station. It was direct-coupled to an alternating current (AC) generating plant, which produced electricity to power the axle-mounted traction motors of the locomotive. Each locomotive's overall power output was governed by the size of the engine. Giant radiators and cooling fans (blowers) directed cooling air to the engine and traction equipment. The diesel engine also drove an air compressor which maintained an air supply for the train's brakes, whistle and, in many cases, control systems. The engine is particularly interesting because it was sectioned as a training and demonstration unit by workshop tradesmen and apprentices at the New South Wales Railway's Chullora workshops. It was built up from the engine base of engine No. 9268 and the engine block from engine No. 14599 together with other damaged or worn components in the workshop. An electric motor was fitted enabling the moving parts to be observed and the engine painted in particular colours to indicate various parts of the engine: orange for the exhaust system, blue for the cooling, yellow for lubrication and red for fuel. The sectioned engine was first displayed at an open day at the workshops on 4 October 1990. However, it was never formally used as a training aid due to changes and downsizing within the then workshops branch and remained on display at the Diesel Engine Maintenance Centre until the closure of the complex in 2001. The advantages of diesel-electric over steam locomotives was that diesels were more powerful, cleaner and faster and could operate around the clock without the coaling, watering, lubricating and ash removal required for steam locomotives. Also, they did not stress the track with the pounding force of the reciprocating (side-by-side) components of the steam locomotives, resulting in less track maintenance. While two steam locomotives coupled together each required a crew, multiple diesel units required only one crew per train. Furthermore, diesels brought most towns in New South Wales within a 12-hour range for freight deliveries and their lower centre of gravity meant they could travel at faster speeds on curves compared to steam locomotives. Conditions for rail crews were vastly improved on diesels. Instead of the hot, dirty cab of a steam locomotive, a diesel offered a working environment more like a compact office, with cooking and toilet facilities. Heavier loads could be hauled and schedules reduced while the introduction of larger freight rolling stock with improved bogies gave a swifter turnaround. Despite this, the transition to diesels was slow, with most Australian rail systems persisting with steam locomotives until the late 1960s or early 1970s. A total of 401 New South Wales diesel-electric locomotives were built with Alco engines and this one is very representative of the type. By 2001 many of the locomotives still remained in government, private and heritage service. This sectioned Alco diesel locomotive engine represents three major changes in the motive power of the NSW Railways: the departure from the general practice of designing and building locomotives in the steam train era in the workshops of the NSW Railways; the reliance on railway technology mainly from the United States to provide motive power for the NSW Railways and the rise of the diesel era in the operation and development of the State's railway network after World War II. Margaret Simpson, Curator March 2015 Information provided in 2001 by Keith Audet, former NSW railways workshop manager Simpson, Margaret 'On the Move; a history of transport in Australia', Powerhouse Publishing, Sydney, 2004.

Loading...

Summary

Object Statement

Sectioned diesel-electric locomotive engine, Alco 251C, 12 cylinder, V configuration, four-stroke, metal, made by Alco Products Inc, Schenectady, New York, United States of America, after 1965

Physical Description

Engine, diesel, full-size, diesel-electric locomotive engine, sectioned, Alco 251C, 12 cylinder, V configuration, four-stroke, metal, made by Alco Products Inc., Schenectady, New York, USA, after 1965, assembled from former New South Wales railways' diesel-electric locomotive engines, sectioned by tradesmen and apprentices at Chullora railway workshops, Chullora, New South Wales, Australia This engine is the power plant of a NSW railways Mark II 44 class and 45 class diesel-electric locomotive. It is a water-cooled, turbo-supercharged, V12 cylinder, four stroke cycle diesel engine with an open combustion chamber with solid fuel injection and removable cylinder liners. The engine has a fabricated welded steel base frame which acts as a lubricating oil reservoir. The base frame includes engine mounting brackets and mounting surfaces for the cylinder block, water and lubricating oil pumps. Inspection covers provide access to the crankshaft and piston assemblies. The fabricated cylinder block is mounted on top of the base frame and supports the major components of the engine: crankshaft and bearings, piston and cylinder lining assemblies, camshaft, fuel oil pumps, cylinder heads and the turbo-supercharger/aftercooler assembly. A separate cast iron cylinder head is provided for each cylinder. Each contains two exhaust valves, two air inlet valves, fuel injector, valve gear, exhaust outlet and cooling water outlet. An electric motor has been fitted to drive the moving components of this display engine and to assist interpretation of the engine's operation. Various paint colours have been used to differentiate each engine system, namely, orange for the exhaust system, blue for the cooling system, yellow for the lubricating system and red for the fuel system. Many components such as the crankcase, fuel injector, turbo exhaust and water pump have been sectioned to reveal the construction and operation of the engine. Engines such as this one represent one of four major components of the diesel electric locomotives they power. These are in sequence the diesel engine, traction generator, cables and contactors (switches) and, lastly, bogies fitted with traction motors, gearboxes and wheels. The diesel engine is direct coupled to a traction generator which provides electrical power to the traction motors by means of electrical cables and contactors. The 251C engine developed the same power as the 251B but some minor design changes were made to the 251B to improve its reliability.

DIMENSIONS

Height

2600 mm

Depth

1750 mm

Weight

13500 kg

PRODUCTION

Notes

The American Locomotive Company or "Alco" was formed on 24 June 1901 with the merger of the Schenectady Locomotive works of Schenectady, New York, which had been established in 1848, with seven other steam locomotive manufacturing companies namely; the Brooks Locomotive Works of Dunkirk, NY; Dickson Manufacturing Co. of Scranton, PA; Cooke Locomotive & Machine Co. of Paterson, New Jersey; and the Manchester, Pittsburgh, Rhode Island and Richmond Locomotive Works. This was followed in 1905 with the addition of the Rogers Locomotive Works of Paterson. For a short time the company examined the possibilities of product diversification and briefly produced a line of trucks and automobiles in Rhode Island. In 1924 the company produced the first commercially successful diesel-electric locomotive, a diminutive 300-hp engine for the Central Railroad of New Jersey. From here began a long history of co-operation with the General Electric Co. in producing many types of electric locomotives. This was followed in 1929 with the production of the first diesel-electric passenger locomotive for the New York Central railway. In the same year McIntosh & Seymour's diesel engine plant at Auburn, NY, was purchased with over 25 percent of its production during the 1930s devoted to internal combustion locomotives. By this time Alco was said to be one of the two or three world leaders in locomotive production. During World War II the company built dual service steam locomotives as well as tanks, tank destroyers, marine boilers and minesweeper propulsion engines as well as diesel switchers. In 1941 Alco built the largest steam locomotive in the world, the 'Big Boy', for the Union Pacific Railroad. By 1946 Alco's production was 75 percent diesel propulsion. Its traditional partner, General Electric was represented in the electrical gear of every locomotive. The last of 75,000 steam locomotives was produced in 1948 but by then the firm controlled 40 percent of the diesel locomotive market. By 1950, locomotive production in the United States was almost exclusively for diesel electric traction. Alco began to succumb to its competition, among which was its former ally, GE. In attempt to survive the 1950s and 1960s, Alco expanded to include many fields of civilian and heavy military manufacturing including large steel pipe, pressure vessels, missile parts and nuclear power generation equipment. In 1955 the firm changed its name officially to Alco Products Inc. to emphasise the diversification of products manufactured and in 1965 most of its assets were purchased by the Worthington Corp., later Studebaker-Worthington. By 1969 the Schenectady plant was closed and leased to GE for turbine generator production. The following year Studebaker-Worthington Inc. sold Alco to the White Motor Corporation. However, the Alco names survive, as from 1977 the firm has been part of the General Electric Company Limited of England which changed the name to Alco Power Inc. Its former plant in Auburn, NY, still manufactures diesel power plants and parts to support Alco locomotives still in service. Specifications of Alco 251B and 251C engines Cylinders: 12, "V" configuration Cylinder bore 9" (229mm) Stroke 10½" (267mm) Maximum power 1950hp (1455kW) Power available for traction 1800hp (1343kW) Displacement 8016cu.in. (131 462cc) Compression ratio 13:1 Engine speed 400 rpm at idle; max 1000rpm Rotation Clockwise from turbo-supercharger end Cylinder numbering Right and left from turbo-supercharger end Lubricating oil capacity 170 gallons (773 litres) Weight (dry) 32,300lbs (14 651kg)

HISTORY

Notes

The diesel engine is an internal combustion engine that employs compression as a mean of raising the temperature of fuel and air in a combustion chamber to cause ignition. This differs from the principle of a petrol engine that uses a spark plug to ignite the fuel air mixture. Diesel engines are known for their high thermal efficiency compared with any other type of internal or external combustion engine. Dr Rudolf Diesel patented the first combustion ignition engine (the diesel engine) in 1892, but it was 1912 before the first diesel engine powered a locomotive. In that year a diesel locomotive was operated on the Winterthur-Ramonshorn Railway in Switzerland but with little success. The main disadvantage to the development of diesel-engined locomotives at that time was their poor power to weight ratio. A significant development that helped to overcome this problem lay in the development by the American company General Electric in 1917 of an electrically powered locomotive in which the power was generated by a diesel engine. Other American companies including Baldwin and Westinghouse also worked on the development of improved diesel locomotive designs in the 1920s and 1930s. In the years following World War 2, the diesel locomotive was rapidly developed in the United States at the expense of inefficient steam locomotives. While diesel engines required high manufacturing tolerances, they could be used more adaptively (unlike the more specifically-purposed steam locomotive) on almost any part of the railroad network. The costs of operating and maintaining diesel locomotives was far less than their steam equivalents, partly because they could be started and operated in minutes rather than hours. Furthermore, crewing required far less labour and much less heavy work. Australia's first mainline diesel (or more correctly diesel-electric) locomotives went into service in Tasmania in August 1950. They were Tasmania's X class built by English Electric in the United Kingdom. This was followed on 22 September 1951 with the inaugural run of the Commonwealth Railways' first mainline diesel locomotive, the 'Robert Gordon Menzies'. New South Wales followed two months later when the first pair of 40 class diesel-electric locomotives was put into service hauling a goods train from Enfield, Sydney to Broadmeadow, Newcastle, on 30 November 1951. The 40 class were the first main line diesel electric locomotives purchased by the NSW Railways. They signalled the beginning of the end of the steam era in this state. In all, twenty 40 class locomotives were ordered. They were all built at the American Locomotive Company's Montreal works and were fitted with an Alco 244H series engine of 1,750hp (1305kW). It is interesting to note that Victoria's first mainline diesel locomotive, the Harold W. Clapp, went into service in July 1952, the same month as Australia's largest steam locomotive, and the NSW Government Railway's only articulated steam engine, the AD60 Beyer-Garratt went into service in NSW. The diesel era heralded a new age of railway operation as the new diesel locomotives were very reliable, had a high ratio of availability, and were easy and economical to operate. Most diesel-electric locomotives commissioned by the NSW Railways in the 1950s-1970s were assembled locally using equipment imported from the United States. This was a significant and permanent departure from the practice of the Railways in the steam era in which much locomotive design and production was carried by the Department's extensive and resourceful workshops. Diesel electric locomotives had brought most towns in the State within a 12-hour range for freight deliveries. They had a lower centre of gravity so could travel at greater speeds on curves compared to steam locomotives. Unlike steam locomotives, diesels did not stress the track with the pounding force of reciprocating components, resulting in less track maintenance. Locomotive maintenance costs were lowered with diesels and multiple units (more than one locomotive "coupled" together) required only one crew per train. In 1955 six diesel-electric locomotives of 1750 hp and designated the 42-class were delivered for NSW express passenger service. They were built locally by the Clyde Engineering Co. in the Co-Co wheel configuration (two independent 6-wheel bogies with all axles driven) but featured engines by the American company, General Motors EMD-567C. A significant step in local production was reached when the same engines were assembled at the Australian Electrical Industries Auburn plant in Sydney. This company and fitted the engines into the new 43 class locomotives that were also assembled by the same company. The 43 class entered service from 26 September 1956, exactly 101 years since the first day of operation of the NSW Government Railways. Another local contractor, A E Goodwin Ltd of Auburn, Sydney, built 91 of the new 44 class locomotives fitted the new 251 series Alco engine. Locomotive 4401 entered service on 8 July 1957 powered by an Alco 251B engine. The 44 class were an example of an Alco World Series locomotive, an essentially standard design used by many of the world's railways and, in Australia, adopted by the South Australian and NSW Railways. A E Goodwin supplied a further 165 locomotives also with the Alco 251B engine and designated the 48-class and introduced in 1959. By the early 1960s the majority of diesel electric locomotives under construction in NSW were being built by A.E. Goodwin with Alco engines. The 251C series engines, of which this sectioned engine is an example, were introduced on the Mark 2 44 class and 45 class locomotives. The first 44 class engine to enter service with a 251C series engine was locomotive 4461 which commenced operation on 12 October1965. A E Goodwin Ltd was also contracted to build the 39 of the 45 class locomotives which entered service in 1962. The 45 class was essentially a cheaper form of the 44 class featuring a hood-type rather than a streamlined body for ease of maintenance. The second generation of diesel-electric locomotives in the NSW Railways was heralded with the 442 class, for which A E Goodwin Ltd received an initial order for 20, later increased by a further 20, to be introduced from 1971. These locomotives were fitted with a more powerful version of the 251C engine but the commissioning of the new class was accompanied by engineering problems with the locomotives' bogies and the financial collapse of the long-standing contractor. The Goodwin-Healing group had been marketing Alco diesel electric locomotives in Australia since 1955. Fortunately this role was taken over by Commonwealth Engineering (Comeng) which was successful in offering an improved version of the 442 class. Comeng completed the unfinished contract for the last six of the 442 class. A new licence deal was forged between Commonwealth Engineering and the then NSW Public Transport Commission for the supply of 30 dual-cab locomotives with the familiar Co-Co wheel arrangement, to be known as the 80-class and powered by an upgraded 251CE engine. Locomotive 8001 was commissioned into service in October 1978. The initial order for 30 of the class was increased to 50 by the new State Rail Authority of NSW in 1980. A total of 401 New South Wales locomotives were built with Alco diesel engines, many of which remain in service in government, private and heritage use. * * * This is the second of two Alco diesel engines sectioned at the State Rail Authority's Diesel Engine Maintenance Centre (DEMC) at Chullora in the late 1980s. In November 1986, the DEMC became an autonomous workshop of the State Rail Authority of NSW. Located in the Boiler Annex Shop at Chullora Workshops, the DEMC was responsible for the overhaul of main line and branch line diesel-electric locomotive engines and components. During 1987-8, a total of 76 diesel engines and 3000 components were overhauled by a staff of 128 with a budget of $8.5m. At the initiative of Doug Paterson, Acting sub-foreman of the engine shop, an Also diesel locomotive engine was sectioned as an apprentice training aid. The unit was completed and displayed at the Chullora Workshops Open Day held in October 1988, following which it was transferred to the Enfield Locomotive Depot, where it was used as a training aid. Two years later, parts from two 44 class locomotive 251C engines were combined into a similar but more complex training aid. The engine's base was from engine no. 9268 and the engine block was from engine no. 14599. Damaged and worn components were used where possible the parts were strategically sectioned. Parts were painted in different colours to indicate the various systems of the engine. A flashing red light was fitted to indicate the power stroke in number 2 cylinder on the left bank of the engine. A compressed air-driven motor was first employed to show the parts in motion but it was considered too noisy and replaced by and electric motor. The engine was assembled by workshop tradesmen and apprentices and displayed at the State Rail Open Day at Chullora on 4 October 1990. However, because of reductions in the apprentice training scheme, the engine was never used as a training aid but was set up on static display outside the DEMC workshop, surrounded by sheets of acrylic mounted in a steel framework to protect it. During the 1990s, the NSW State Government advanced its plans to corporatise State Rail into business units and to contract much of the formerly in-house maintenance work undertaken by State Rail on its rail fleet and infrastructure. Most of State Rail's activity on the massive Chullora site was gradually wound up and the site partially cleared or reconfigured for reassigning to contractors. Within this context, the future of the sectioned 251C diesel engine was in doubt and workshop managers at Chullora were keen to ensure its preservation. An informal approach was made to the Museum in August 2000 to assess the Museum's interest in acquiring the engine as a donation. The Museum expressed its interest in writing, following which the engine was formally offered as a donation to the Powerhouse Museum by Michael Peter, General Manager Workshops, Rail Services Australia, Chullora on 18 October 2000. (Rail Services Australia was a railway contractor and a unit of the Rail Infrastructure Corporation which in turn was a division of State Rail.) However, there were delays in progressing the matter due to a lack of resources to transport, recondition and store the engine and it was a concern to both parties that there was no prospect of displaying it at the Museum. On 10 April 2001, a further letter was sent by Michael Peter re-confirming the offer of donation but reiterating the importance of displaying and interpreting the engine's operation. At this time an opportunity was identified to find an alternative temporary display location for the engine outside the offices of Rail Fleet Services Ltd, a locomotive servicing contractor located within the workshop site at Chullora. Because of its interest in the potential of the engine as a promotional exhibit, this company agreed to return the engine to operating condition as specified by the Museum, relocate it to a hard stand outside their offices and enclose it in a purpose built structure, entirely at the company's cost. The Museum was to provide a suitable interpretive label and other information about the engine. On 25 June 2001, the Museum sent this proposal in writing to Rail Fleet Services Ltd together with a maintenance plan for the engine. No response was received from the company and despite attempts made to revive the matter, no progress was made. The matter lay fallow for several years, during which, on 1 January 2004, Rail Corporation NSW was formed to merge the functions of the State Rail Authority and the Rail Infrastructure Corporation. In late 2009, the Office of Rail Heritage, part of Rail Corporation NSW, approached the Museum to confirm that the Museum was still interested in acquiring the engine. This was confirmed and the process of acquisition was reinstigated but this time with renewed optimism. With the opening in March 2007 of the Powerhouse Discovery Centre, the Museum now had a site with the potential for much greater public access to its collection, perhaps even to display a sectioned diesel engine. Andrew Grant Senior Curator, Transport July 2010 References A Century Plus of Locomotives, Australian Railway Historical Society, Sydney 1965 Audet, K and Longworth J, Sectionised Locomotive Engine, Rail Infrastructure Corporation, Sydney, 2001(?). Longworth, J, Boilers Beauforts and Bogies, Australian Railway Historical Society, Sydney, 1996(?) McNicol, S, SRA Locomotives, Railmac Publications, South Australia, 1981

SOURCE

Credit Line

Gift of Rail Corporation New South Wales, 2010

Acquisition Date

15 July 2011

Copyright for the above image is held by the Powerhouse and may be subject to third-party copyright restrictions. Please submit an Image Licensing Enquiry for information regarding reproduction, copyright and fees. Text is released under Attribution-Non Commercial-No Derivative licence.

Image Licensing Enquiry

Object Enquiry