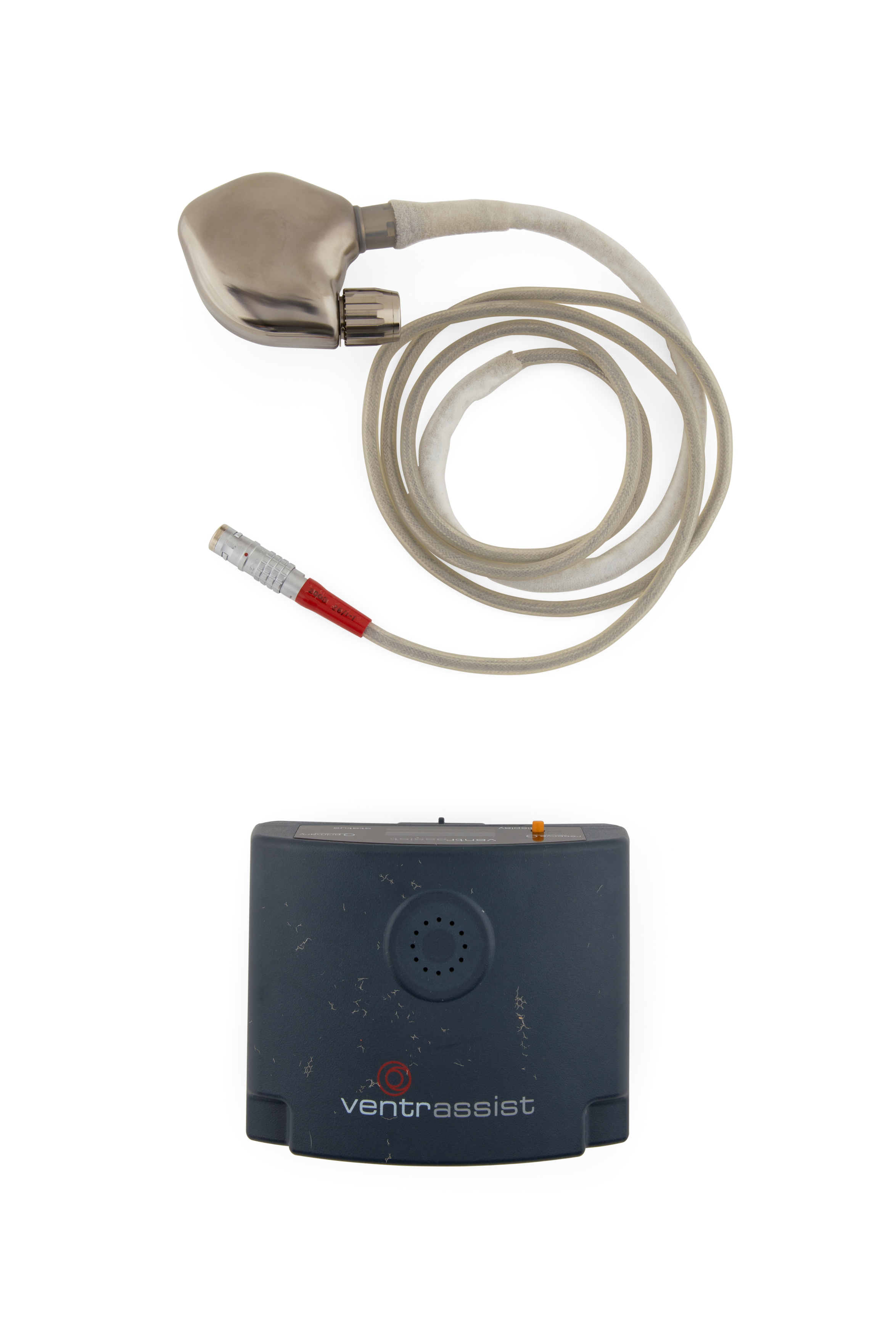

'VentrAssist' implantable blood pump with control box

Object No. 2008/136/1

The VentrAssist is an implantable blood pump designed as a permanent alternative to heart transplantation for people suffering congestive heart failure. It can also provide temporary therapy while patients wait for a transplant. The device addresses the growing health problem of heart failure, for which the only cure is a heart transplant. According to Ventracor there are an estimated 11.2 million sufferers of congestive heart failure worldwide, a total that is increasing by 10 per cent each year. Only about 3000 people receive a heart transplant each year. The VentrAssist technology is unique and when first developed was smaller, lighter and simpler than other heart pump devices. The pump's only moving part is a rotating impeller which 'floats' in the blood, reducing wear and potential for blood clots. The VentrAssist helps the heart to pump blood and does not require removal of the heart, providing the possibility for it to rest and recover. The pump is connected to an external controller and power source through a lead in the abdomen. Designed and developed in Australia, the VentrAssist was first patented in 2001. The first human implant was made in June 2003 at The Alfred Hospital in Melbourne. By 2008, more than 250 implants had been made in 36 centres across ten countries. At this time the product had achieved CE Mark approval to market in Europe, TGA market approval in Australia, and was undergoing FDA trials in the USA. Despite having successful clinical trials, world-leading technology and the efforts of shareholders, global financial turmoil meant the company could not find the funds to continue and Ventracor folded in mid-2009. The VentrAssist received an Australian Design Award and an Engineering Excellence Award in 2006. Locally designed and manufactured, the VentrAssist represents Australian innovation and expertise in medical devices and associated precision manufacturing. It also illustrates the many challenges and efforts involved in successfully bringing technology products to the market. Angelique Hutchison Curator May 2008 Updated 2015

Loading...

Summary

Object Statement

Implantable blood pump with control box, 'VentrAssist left ventricular assist device (LVAD)', metal / plastic, designed by Faculty of Engineering, University of Technology / Ventracor Ltd, 1997-1999, made by Ventracor Ltd, Chatswood, New South Wales, Australia, 2006

Physical Description

Titanium heart-shaped pump attached to a rectangular-shaped externally-worn blue control box via a metal and plastic lead. The control box has a liquid crystal display screen at centre top and four points of connection down the centre back for 'pc', 'reserve', 'primary' and 'pump'.

PRODUCTION

Notes

This device was manufactured by Ventracor Ltd in Chatswood, Sydney, New South Wales, Australia in 2006. The VentrAssist was developed by the Faculty of Engineering at University of Technology, Sydney and MicroMedical Industries (later known as Ventracor) over the period 1997-1999. A large team of biomedical experts developed the device based on an original invention by John Woodard (MicroMedical), Peter Watterson (UTS) and Geoffrey Tansley (UTS/MicroMedical). Initial funding for the VentrAssist was received from AusIndustry as an R&D Start Grant. Animal trials were undertaken from 2000 to 2002, and the first human implant was made in June 2003 at The Alfred Hospital in Melbourne. Extensive clinical trials were undertaken, initially in Australia and later in Europe and the USA. Market approval was received in Europe in 2006 and Australia in 2007, and trials continued in the US in 2008. A successful major US clinical trial was completed in early 2009. But despite the world-leading technology and the efforts of shareholders, global financial turmoil at the time meant the company could not find the funds to continue and Ventracor folded in mid-2009. Ventracor's intellectual property was sold to Thoratec Corporation in 2010. The VentrAssist is a blood pump that connects to the left ventricle of the heart to help its pumping function. The procedure does not require the removal of the patient's heart, and the pump allows it to rest and possibly recover. The pump has only one moving part, a hydrodynamically suspended impeller, that is designed never to wear out or damage blood cells. The device is made of titanium and the inside surfaces are diamond (carbon) coated. It weighs 298 grams and is less than 6cm in diameter, making it suitable for implant in adults and children. When implanted, the pump is connected through the abdomen by the lead to the external controller which contains the battery. The VentrAssist can be used as either a 'bridge to transplant' (BTT) therapy or 'destination therapy' (DT) device. The key innovation embodied in this device is the suspended rotor or impeller. At the time it was developed this feature was unique in the marketplace. In addition the pump had an unconventional shape and look for this type of device. The biggest challenges in the design and development process were making the device reliable and easy to manufacture. John Woodard, co-inventor of the device, describes the process of inventing the VentrAssist: 'We conven[ed] a group of experts from Australia and also from the United States here in Sydney and locked them up in a room for three days and told them they couldn't come out until they had a new design. We brainstormed around the table at UTS for 3 days here in Sydney and the three principal contributors to that were Dr Geoffrey Tansley, Dr Peter Watterson and myself. We then wrote up a patent and used that as a basis for getting a government grant from the Federal Government to start this project. We started effectively with a sheet of blank paper and tried to come up with a different way of doing things.' 'Suprisingly the original concept was pretty good ... the first one we built we put into an animal and it worked pretty well... So we didn't change the concept at all - we did refine the shape of the blades and the impeller to make it a bit more efficient and to damage the blood a bit less, but the first one wasn't bad.' 'The inventive step was comparatively easy - making it manufacturable and reliable is the hard thing.' Dr John Woodard, interview with Powerhouse Museum, 9 June 2004.

HISTORY

Notes

This device was displayed the 2006 Australian Design Awards exhibition at the Powerhouse Museum from July 2006 to June 2007 and subsequently donated to the Museum's collection. A VentrAssist device was also displayed in the 2004 Australian Design Awards exhibition from July 2004 to June 2005, and in the Stop Press showcase in the Success and innovation gallery in 2003. The VentrAssist received the Powerhouse Museum Selection, an Australian Design Award and an Engineering Excellence Award in 2006. In 2006 over 200 entries were received in the Australian Design Awards competition. The judging panel recommended 41 of these products receive an Australian Design Mark and of these, 21 products for an Australian Design Award. The products receiving the Australian Design Award and the Powerhouse Museum Selection were announced at a dinner and awards ceremony on 19th May 2006 at Wharf 8, Sydney. The VentrAssist also received the Powerhouse Museum Selection Award and an Australian Design Mark in 2004.

SOURCE

Credit Line

Gift of Ventracor Ltd, 2008

Acquisition Date

30 June 2008

Copyright for the above image is held by the Powerhouse and may be subject to third-party copyright restrictions. Please submit an Image Licensing Enquiry for information regarding reproduction, copyright and fees. Text is released under Attribution-Non Commercial-No Derivative licence.

Image Licensing Enquiry

Object Enquiry