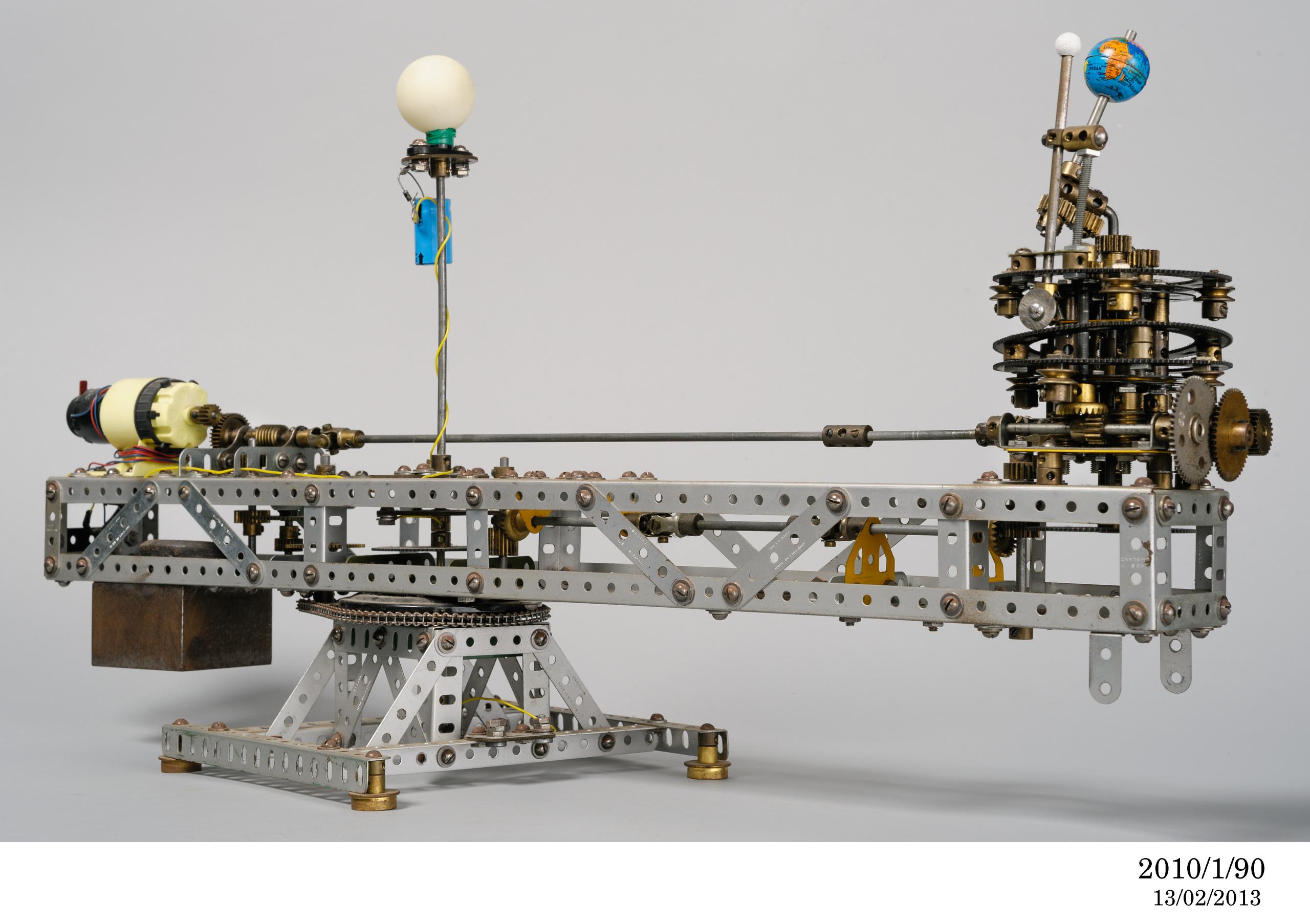

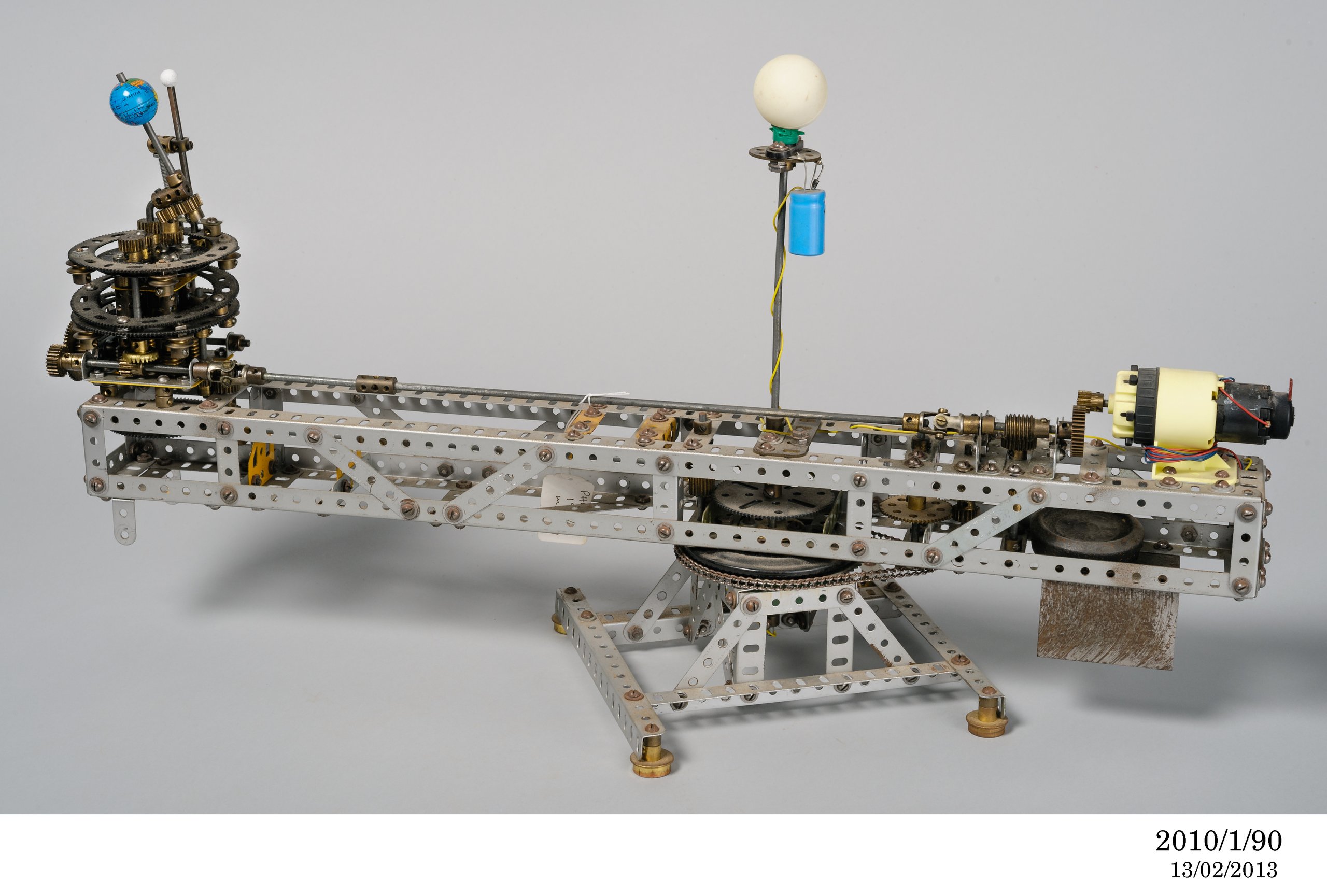

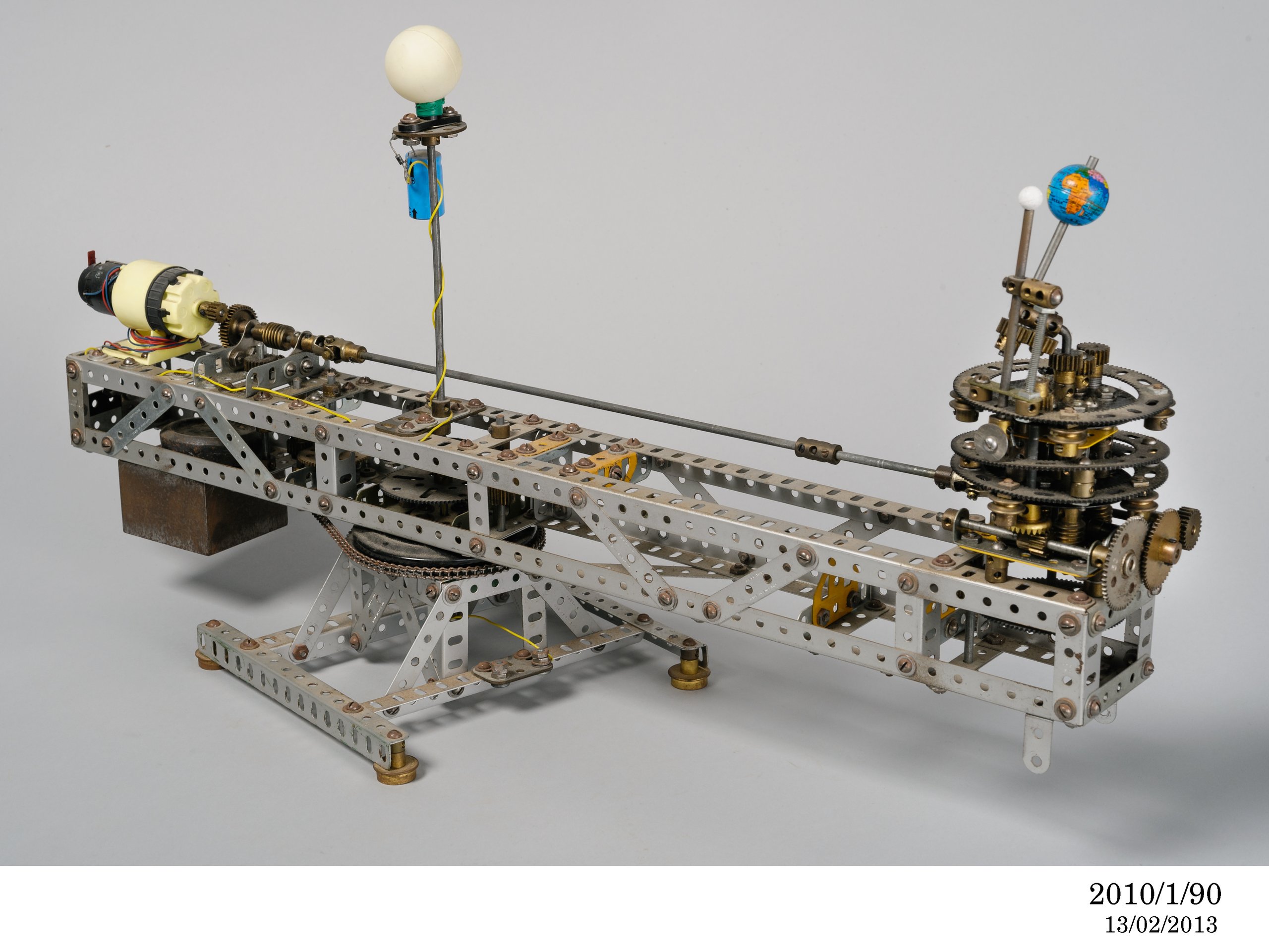

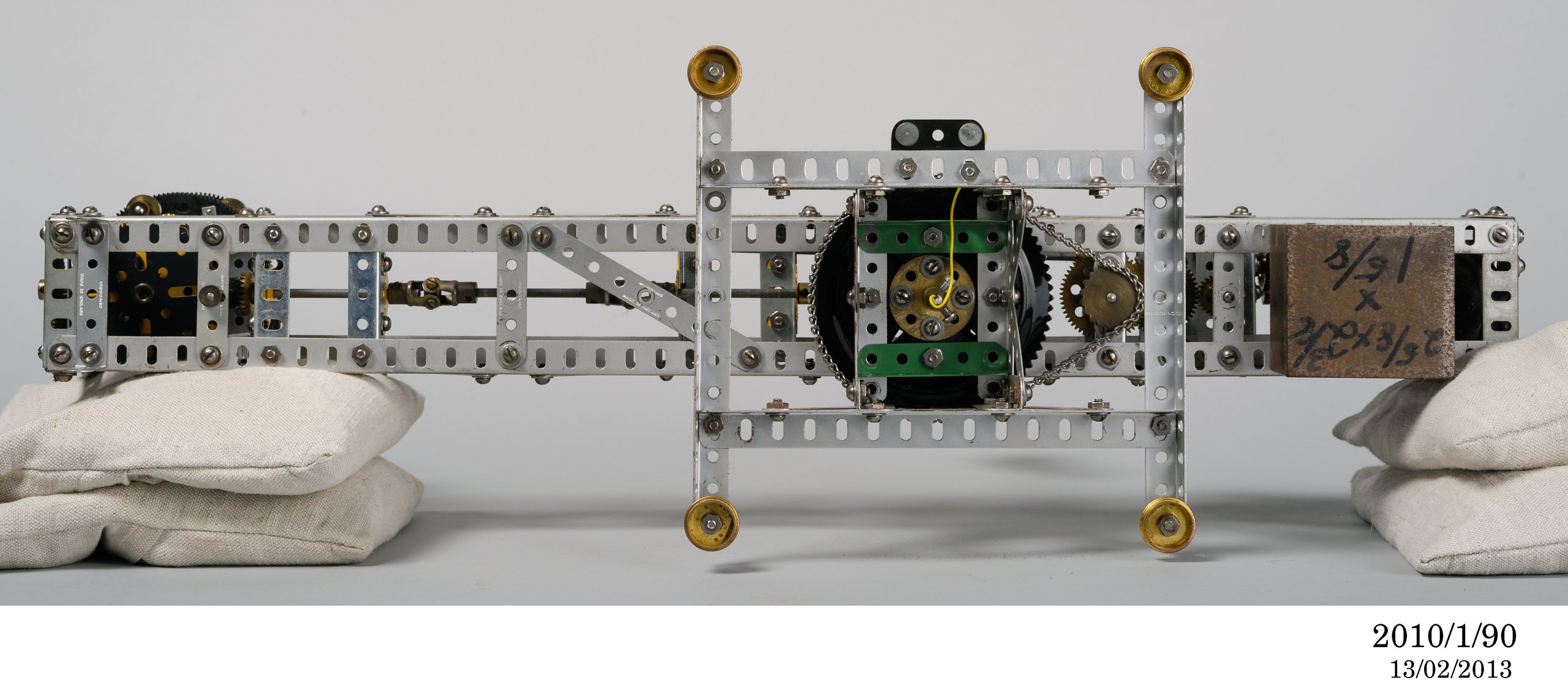

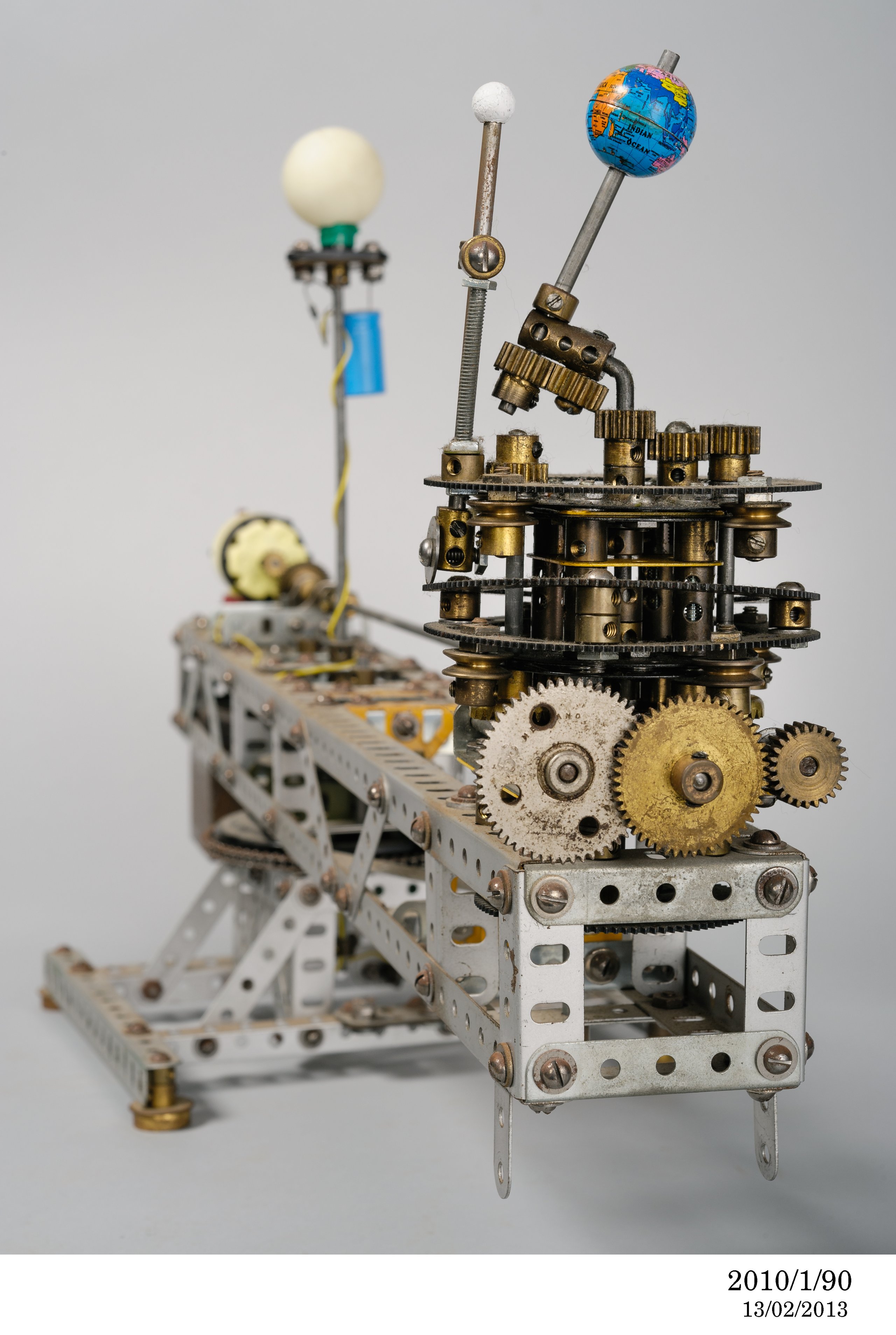

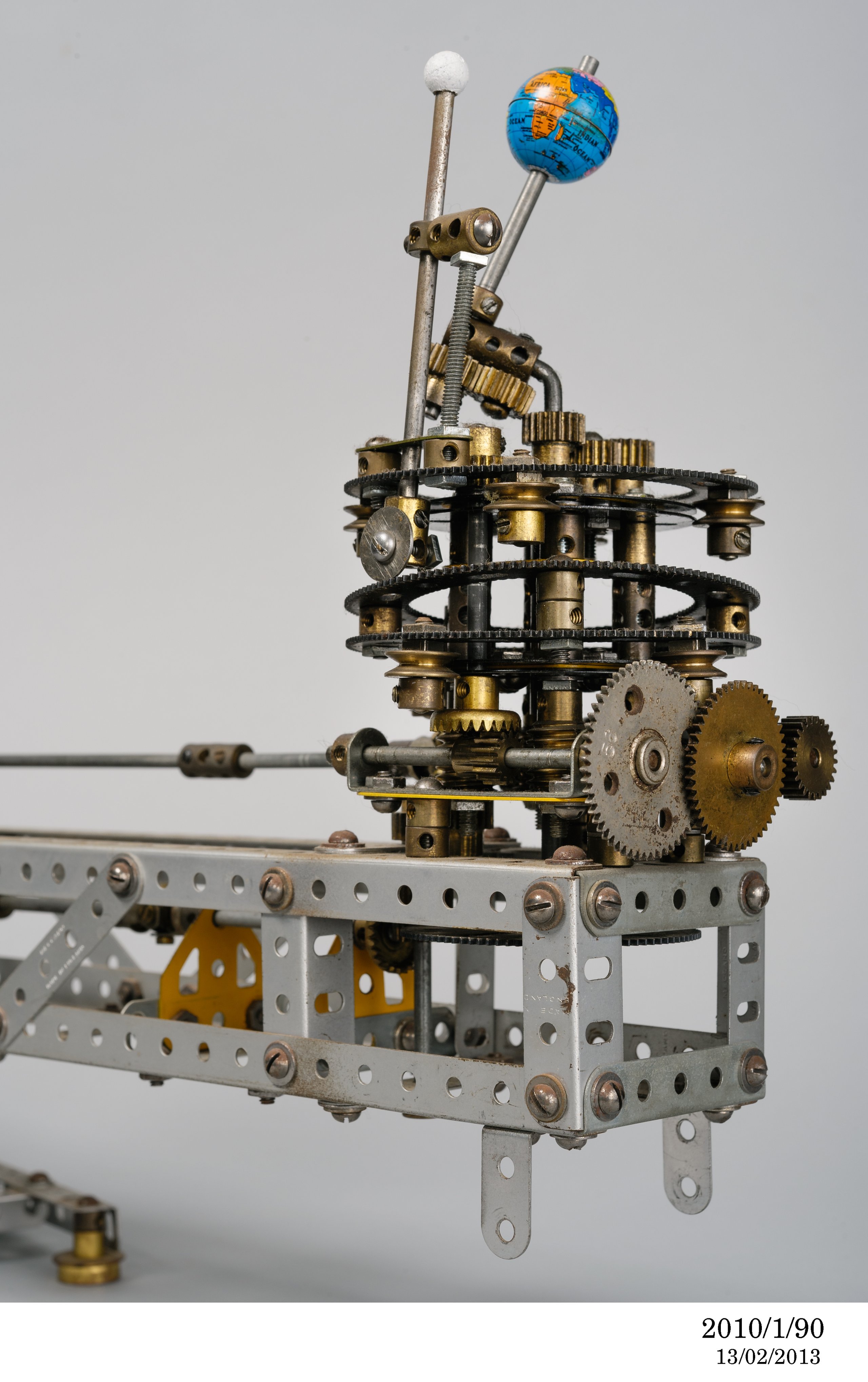

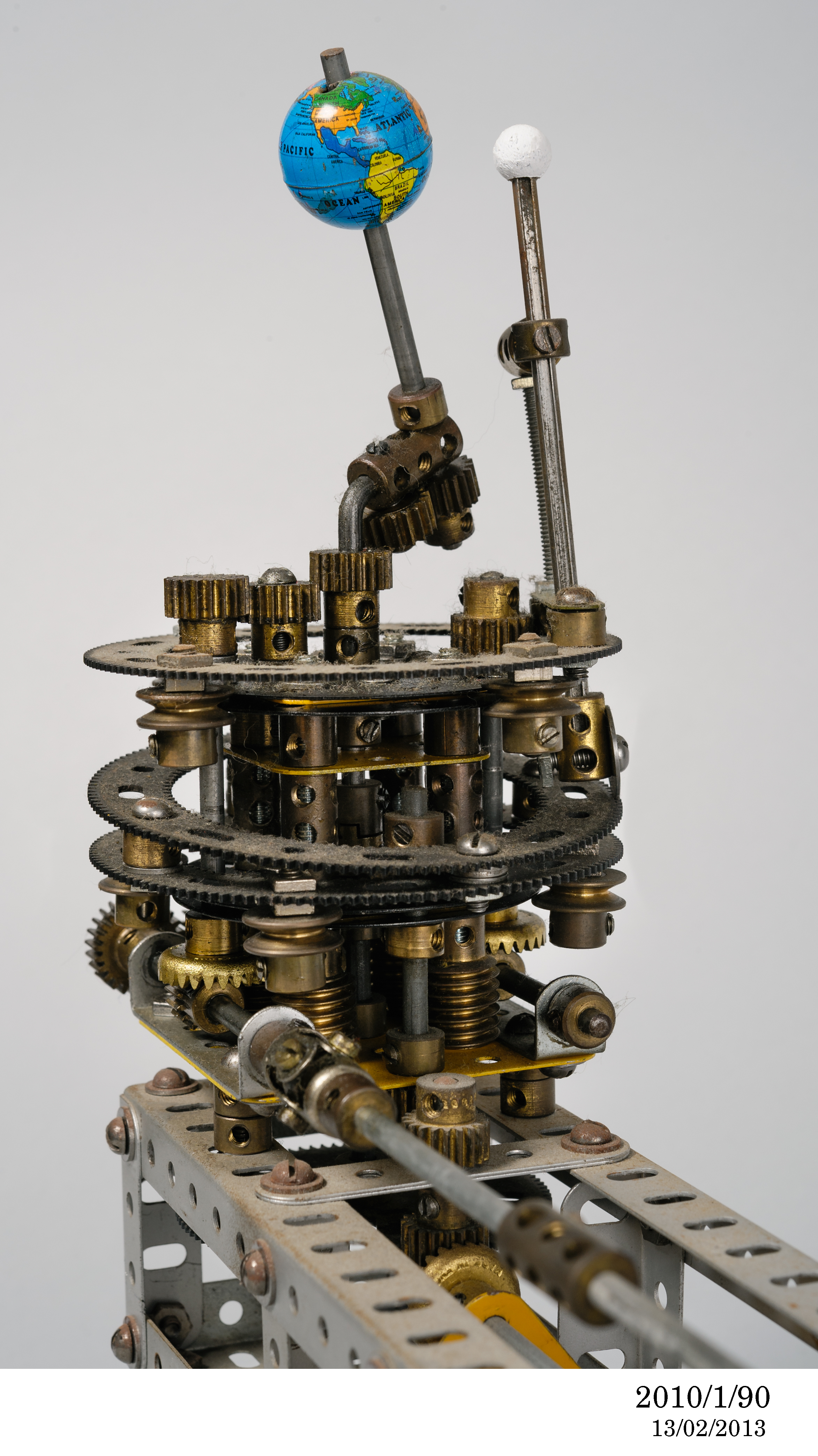

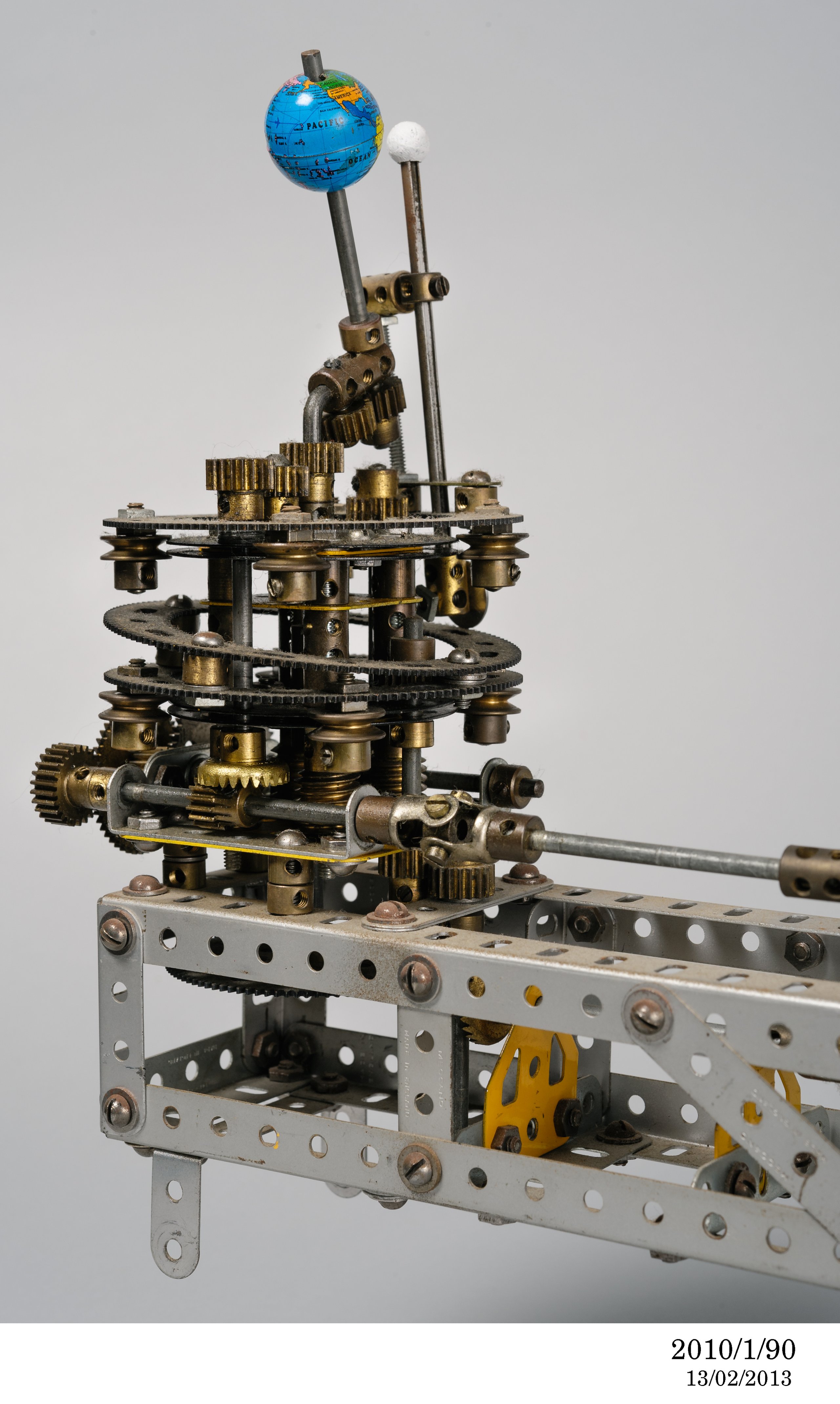

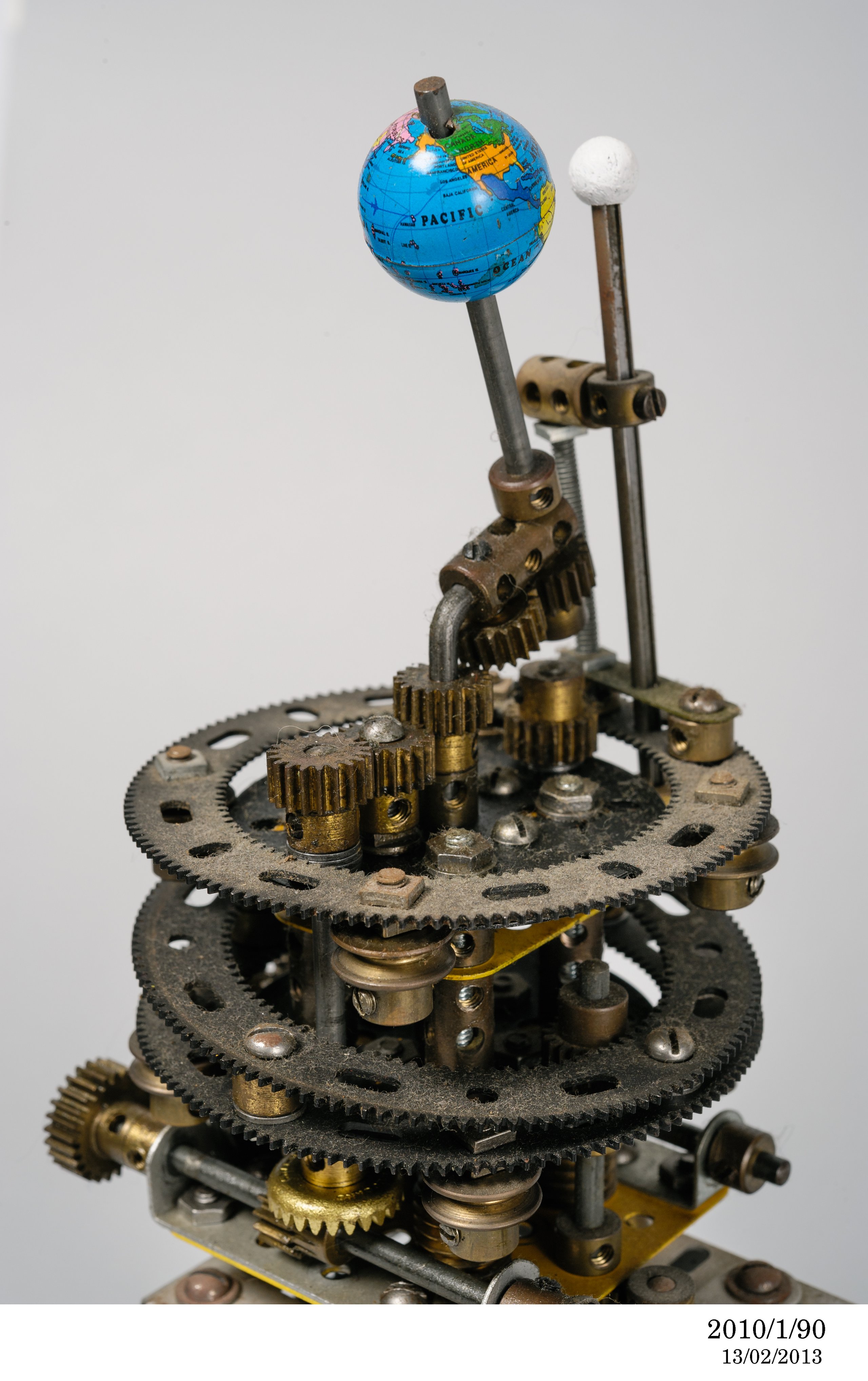

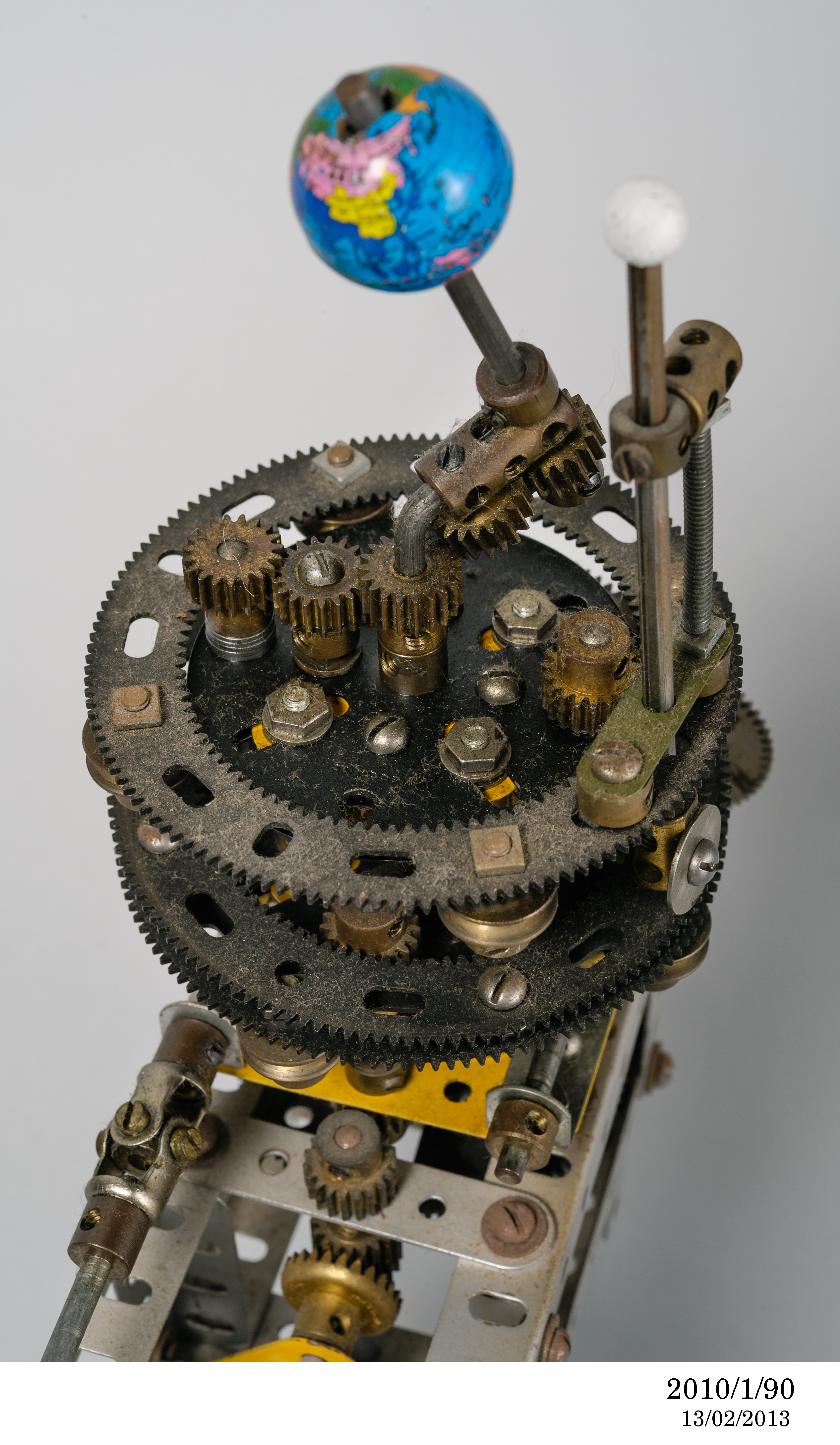

Meccano model of an orrery

Object No. 2010/1/90

This object is part of a collection relating to the history and development of calculating devices assembled by Assoc Professor Allan Bromley of Sydney University, comprising mathematical instruments, slide-rules, mechanical and electronic calculators, electronic analogue computers, computer components, kit computers, education computers, and associated ephemera. Allan Bromley was a lecturer and researcher at the University of Sydney Basser Department of Computer Science from 1978 until his untimely death in August 2002. He specialised in Computer Architecture, Computer Logic and in particular the History of Computing. He was regarded as the world authority on Charles Babbage's Calculating Engines (instigating the building of the Difference Engine No.2 at the Science Museum London) and the Antikythera Mechanism and had extensive knowledge of calculators, analogue computers, logic, stereopsis, totalisators, clocks and time keeping and mechanical engineering.

Loading...

Summary

Object Statement

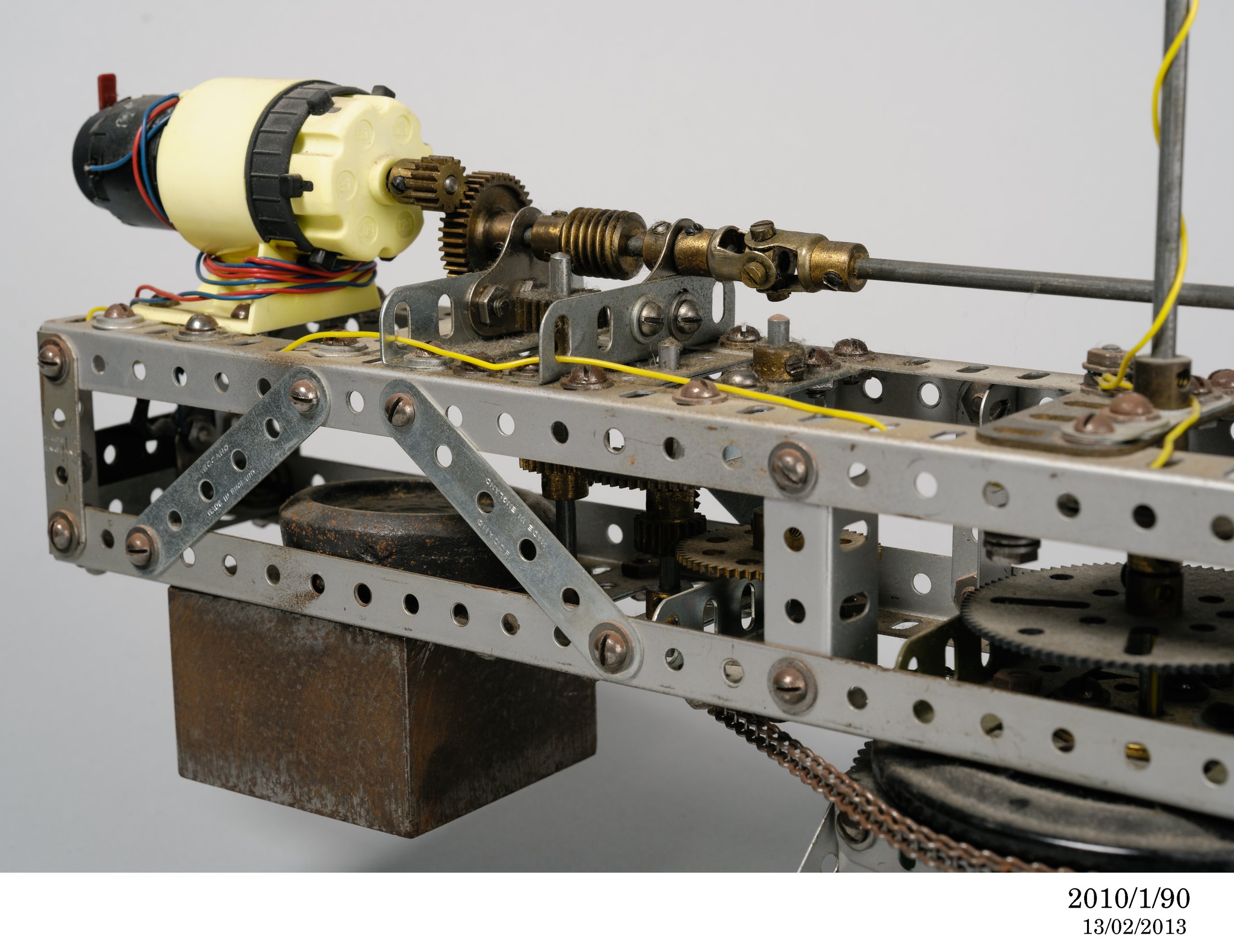

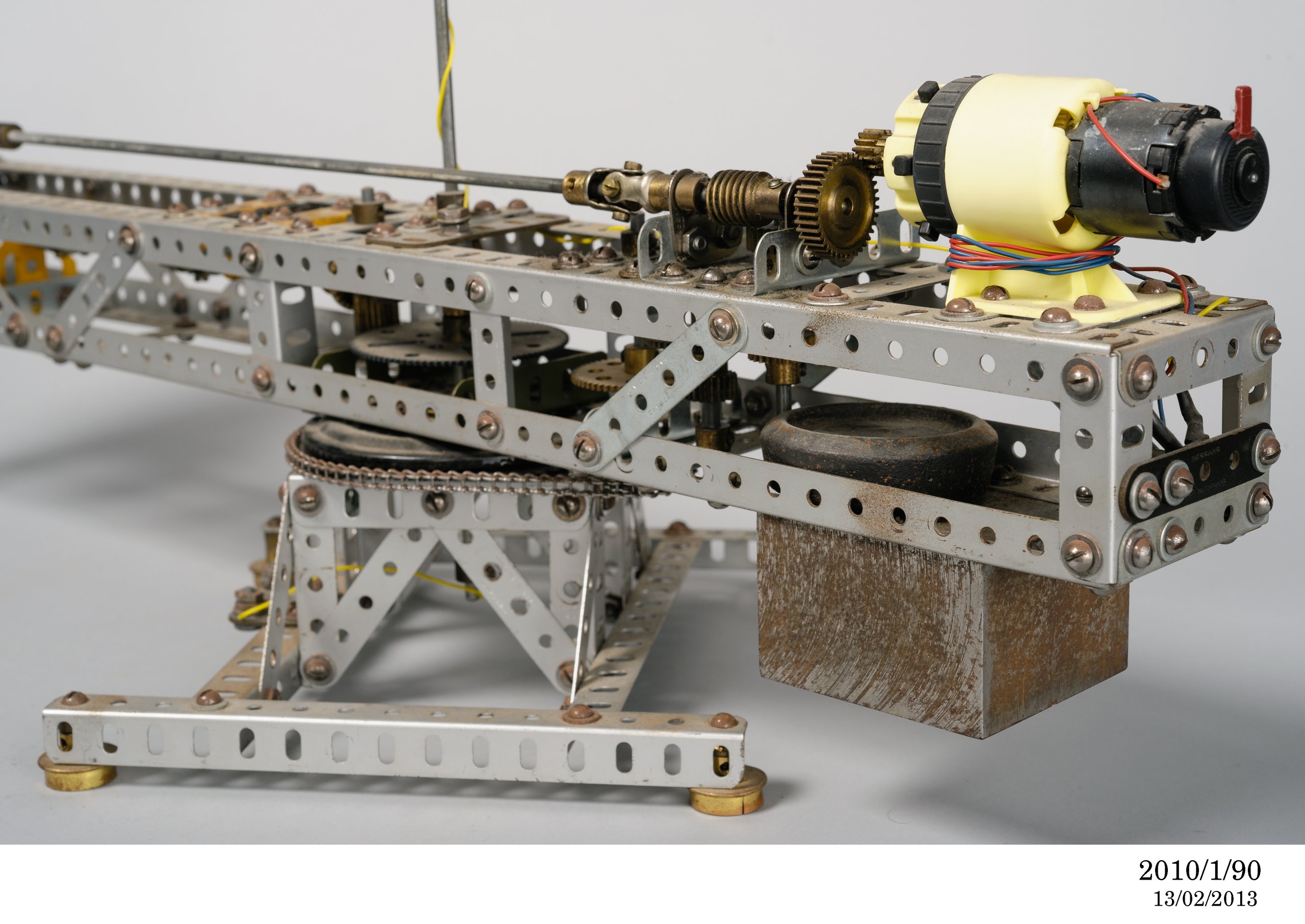

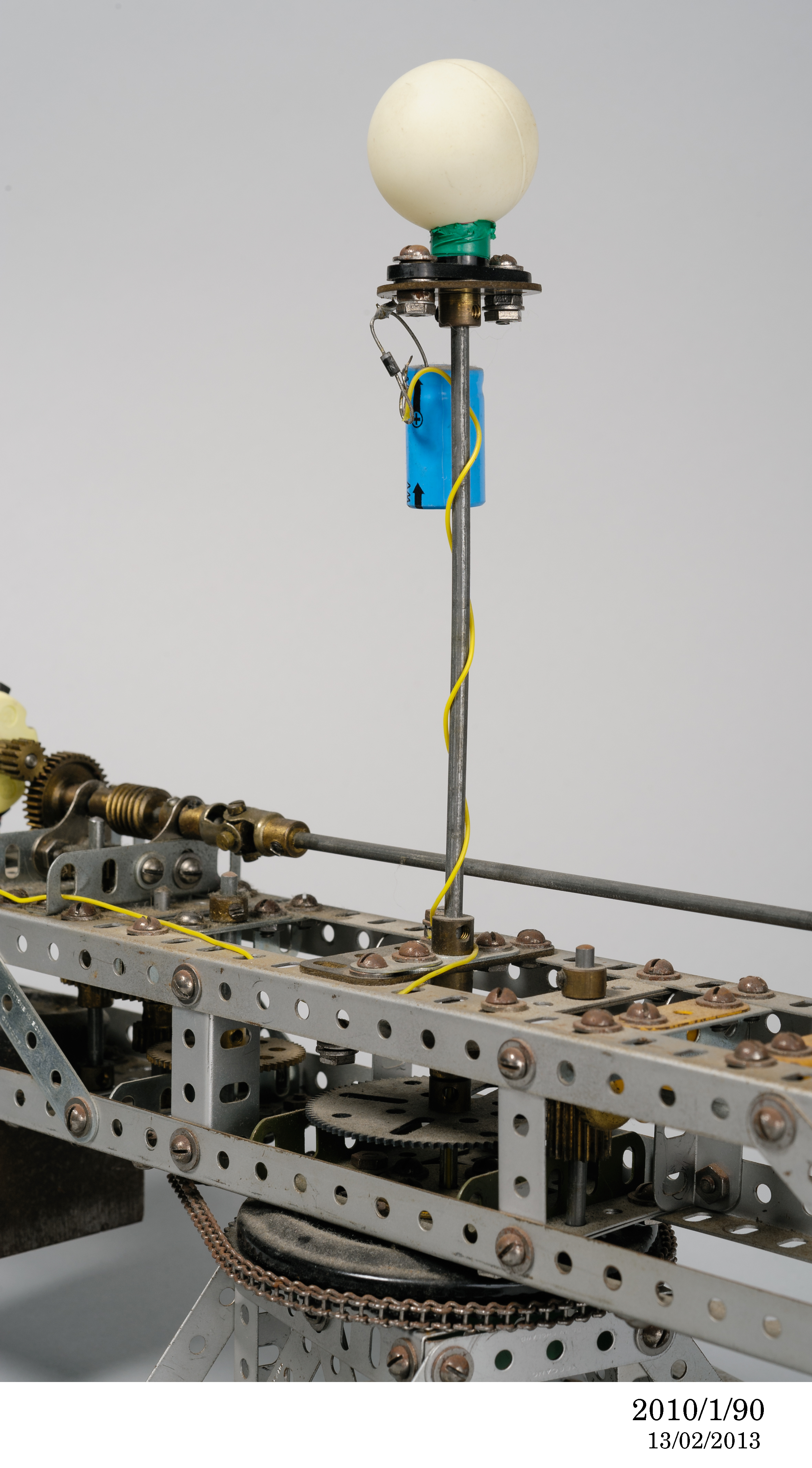

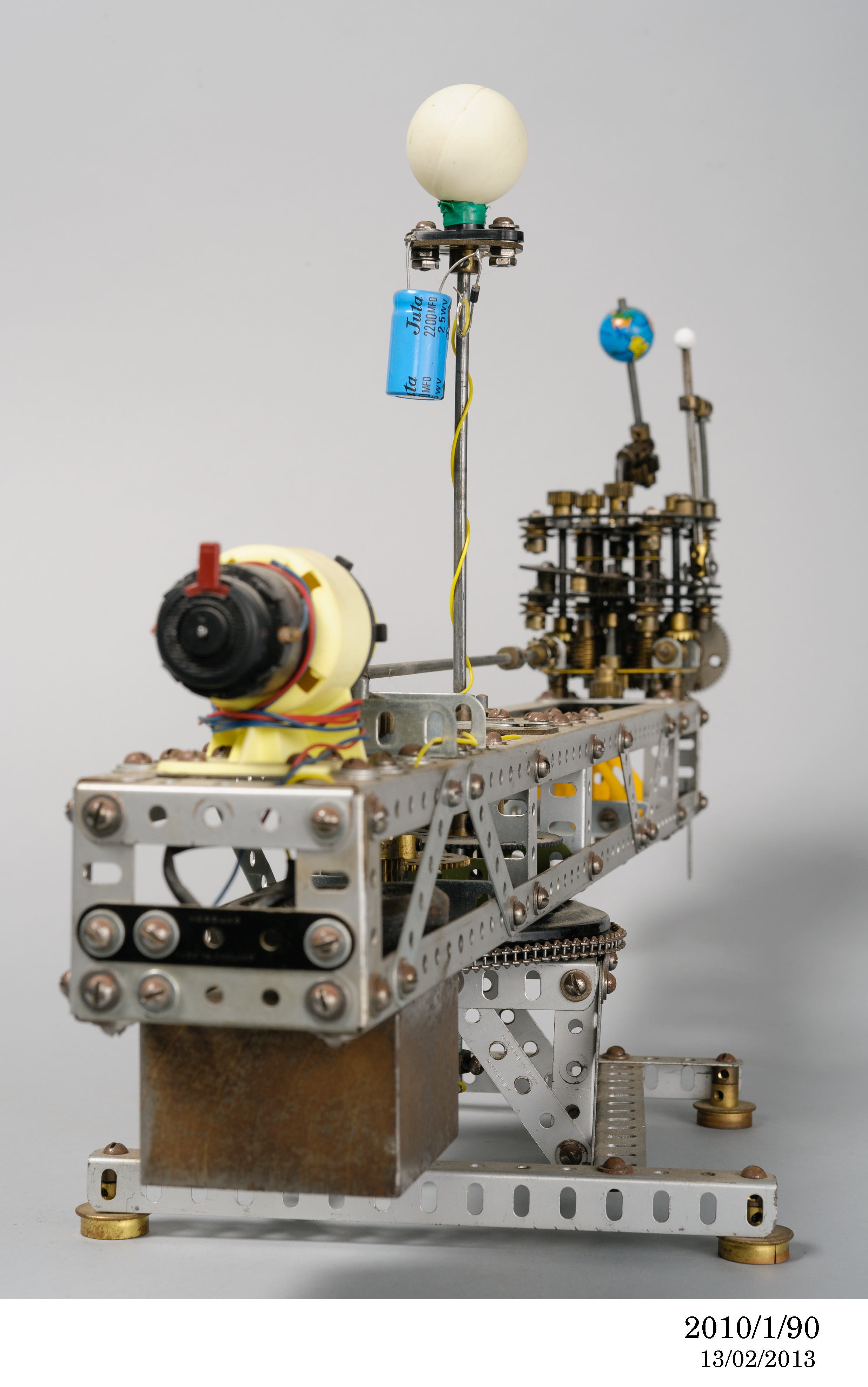

Meccano model of an orrery, metal / plastic / glass / electronic material, made by Meccano Ltd, Liverpool, England. 1960-1975

Physical Description

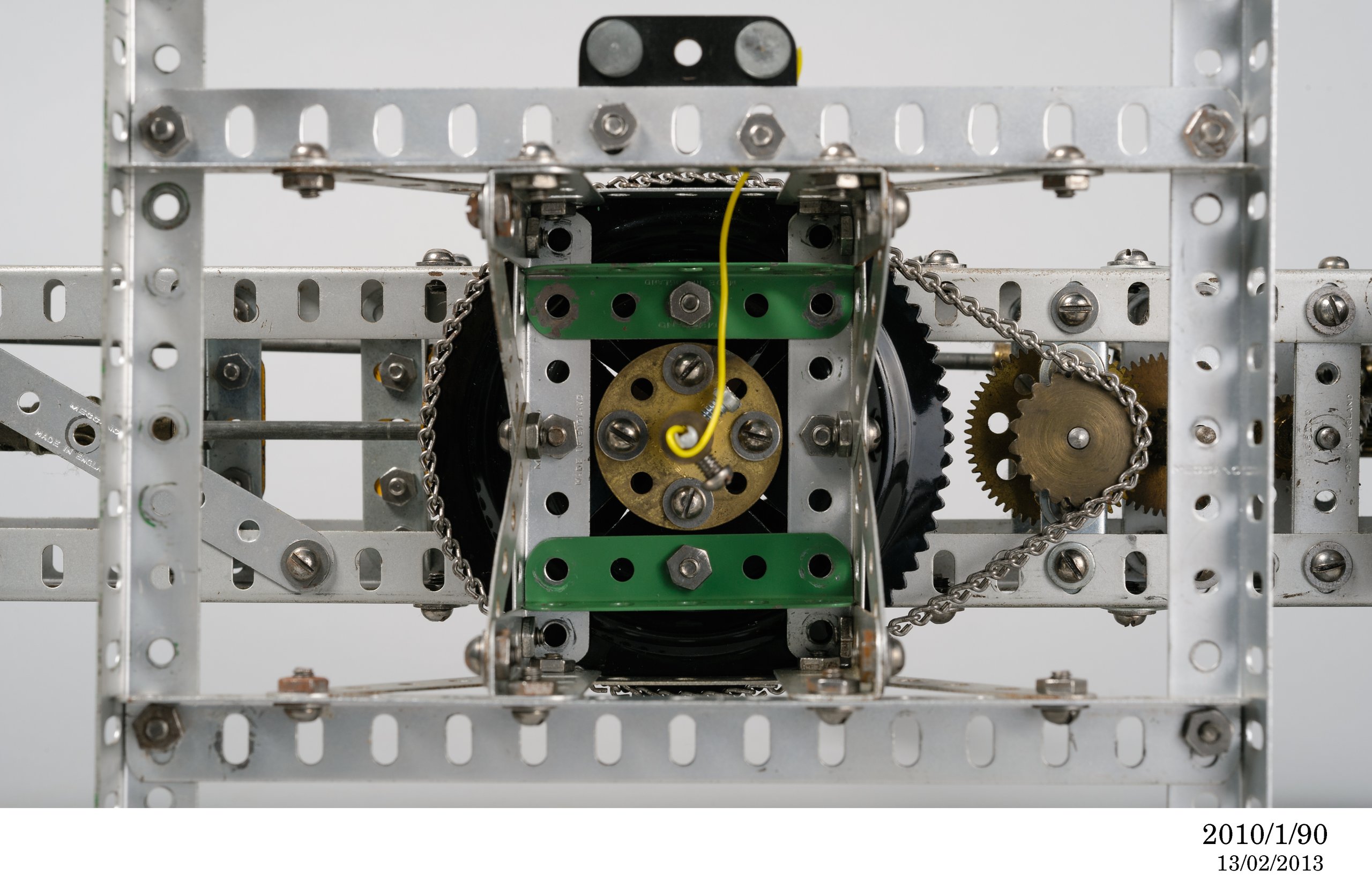

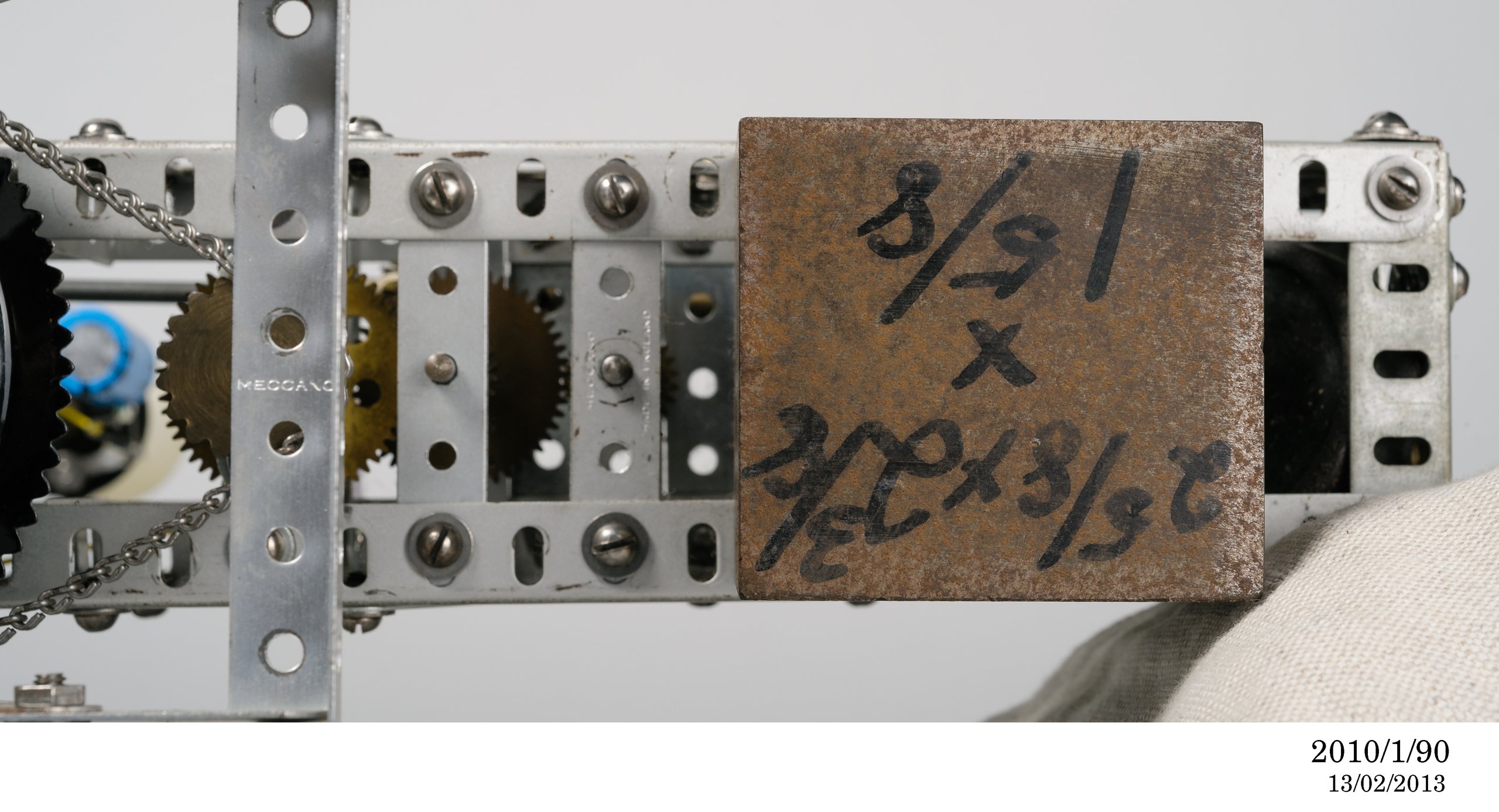

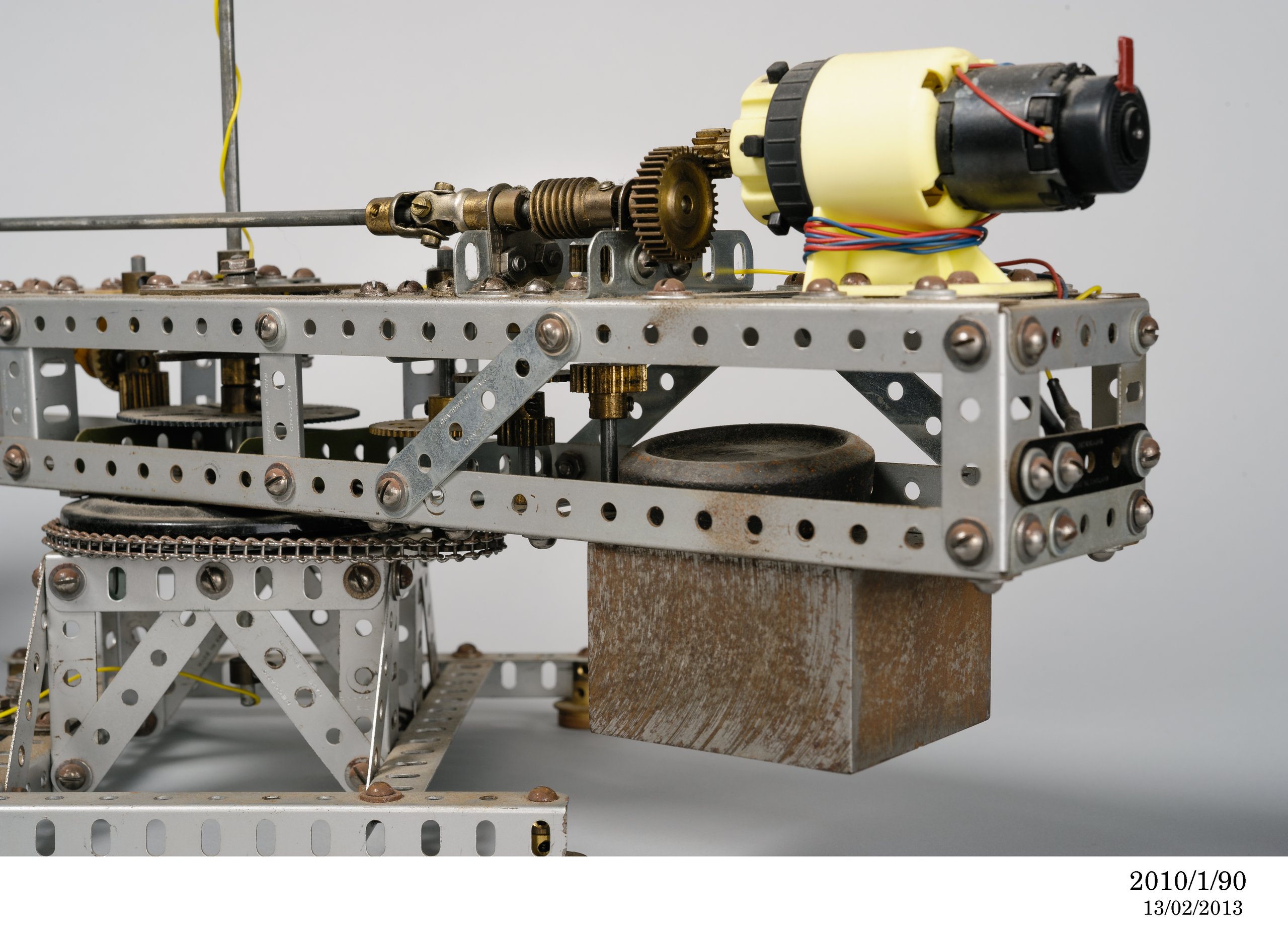

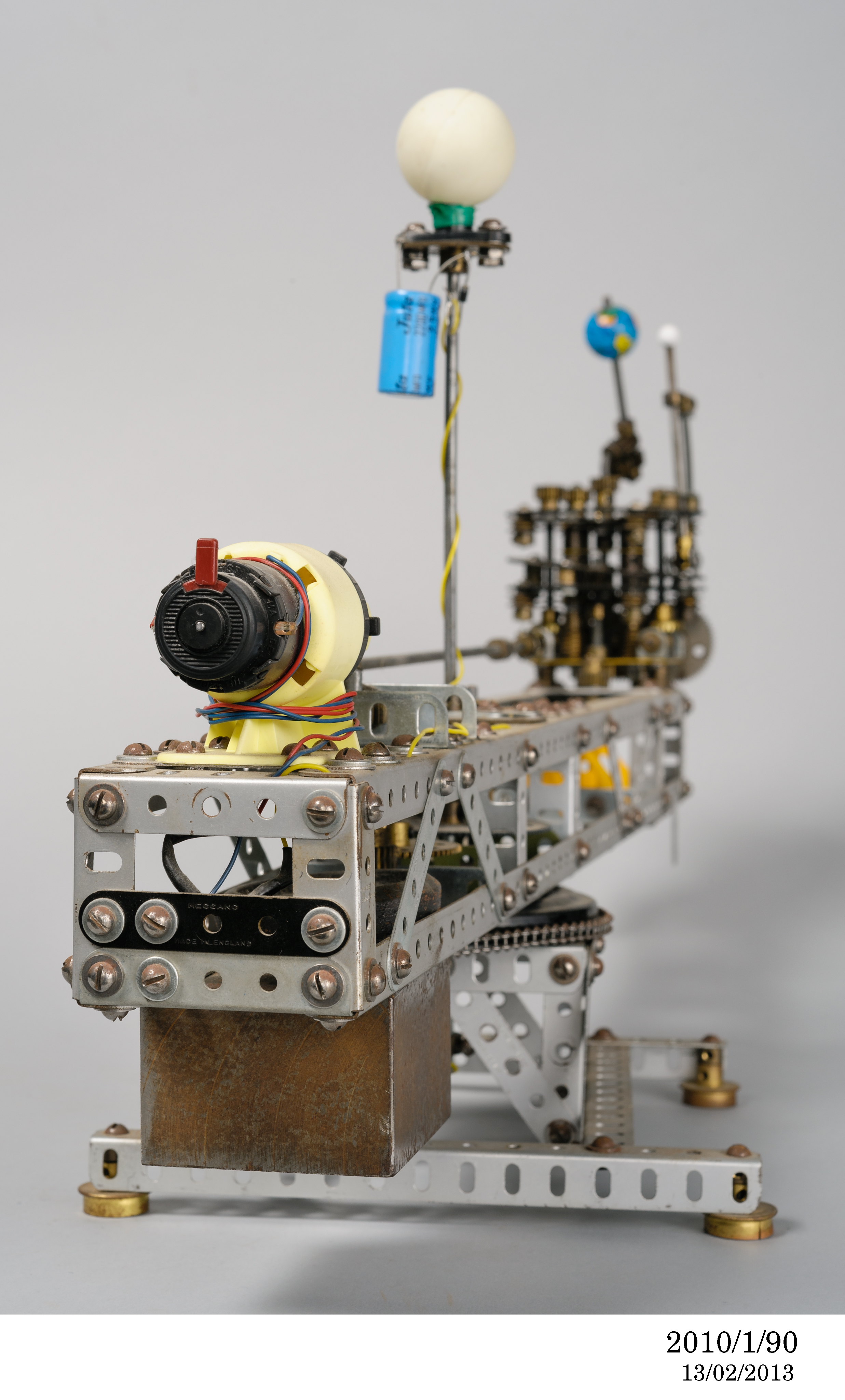

The model orrery is made entirely of standard metal, yellow and green meccano. It is made up of a base consisting of a square frame resting on four feet, which supports the long frame that sits atop a large circular cog to allow for 360 degree rotation. This crane like frame is made up of three sections. The right hand side features the main motor for powering the rotating gears and chains, connected up using a red and blue wiring system. This motor sits on top of the frame, while a large square weight is attached to the underside of and a smaller 8 oz circular weight sits inside the frame. Perched on top of the left hand side is the main mechanism of the orrery. This mechanism consists of a series of small and large gears which rotate against each other to allow the small models of the earth, which spins on its own axis and the moon, which rotates around the earth, to function. A single long metal rod connects the cogs on the right hand side with the mechanism on the left. In the centre of the frame is a long vertical rod housing a small platform adorned with a lightbulb and a ping pong ball. This model represents the sun and can be powered by the blue capacitor which is connected to the motor via a yellow wiring system.

DIMENSIONS

Height

340 mm

Width

195 mm

PRODUCTION

Notes

The Orrery is a mechanical device for illustrating the motions of the planets in their orbit around the sun. Our knowledge of the solar system has increased greatly since Copernicus in 1514 showed that the earth was orbiting the sun, and since Galileo Galilei's observations in 1609, using the new telescope. When Newton provided the basic mathematical building blocks for gravitation and Kepler provided mathematical solutions to the way the planets orbit the sun, it became possible to model the solar system. The Orrery was invented around 1710 by the London instrument and watch maker George Graham under the patronage of Charles Boyle, 4th Earl of Orrery, from whom it was named. The first Orrery was made around 1712 by John Rowley, who was employed by Graham. The mechanical Orrery was in use for several centuries; it was formerly called a Planetarium. The Orrery presents the planets in a scale model, as seen from outside the solar system. A dynamic feature of the Orrery is its ability to explain Kepler's laws of planetary motion in an interesting way. The model also shows the division of the inner planetary system into two principal parts. Mathematicians recognise that most systems containing three bodies or more are chaotic. Therefore, for a complex system like the solar system there is no analytical solution for pin-pointing where all the planets will be at any given time. To predict the future positions of the planets, a mathematical approach is used, called Numerical Integration, whereby the current positions and momenta provided by astronomers are used to predict increments in positions and moments, resulting from a time increment. These are then applied repeatedly until the required future time. The numerical integrators, however, introduce errors at each incremental step, therefore a great deal of mathematical analysis has been expended to assess various methods of modelling different systems.

HISTORY

Notes

In 1898 in Liverpool, UK, in a backyard workshop Frank Hornby invented for his children the very first pieces of the bolts and nuts system that has made today the international brand awareness of Meccano. Frank Hornby patented his nuts and bolts assembling system and marketed his first set under the name Mechanics Made Easy. The name Meccano made its appearance in 1907. The first Meccano plant opened in Liverpool in 1907. It was to be replaced rapidly by the factories located in West Derby Road and then in Binns Road. That enabled a higher production capacity to meet the growing demand. Based upon its worldwide success, Meccano launched two new production sites: in Berlin, in cooperation with Marklin in 1912, and in Belleville (France) in 1920. Faced with growing sales in France and its colonies, the Belleville production unit could no longer meet the demand. Therefore, in 1930, a larger factory was built in Bobigny, outside Paris, similar to the mother-plant in Liverpool. This Bobigny-based factory managed to produce in 1951 more than 500,000 Meccano sets despite steel shortages. A new factory was built in Calais in 1959 and is still today the sole production center for Meccano sets worldwide. From the hands of the Lines Brothers, who had acquired it in the 50's, the French subsidiary Meccano SA went on to join the French company Miro (maker of board games) to form Miro-Meccano. In the late 70's, Meccano was taken over by the American packaged goods company General Mills, which then acquired the English branch of the company in 1981. This purchase marked the final relocation of English production of Meccano to the factory in Calais, which became the only site worldwide for production of Meccano. However, Meccano was not a priority: no attempt was made to market the product and sales fell tremendeously down in the competitive construction toy market. In 1985, General Mills sold Meccano: development of a plastic mold injection system to complement the production of metal parts. In 1999, the Meccano Group set up a policy of reorganization of the Meccano brand, based upon two generic construction systems (plastic and metal). Each system covers product lines which meet the expectations of children aged from 4 to 15 years old. Since May 2000, Meccano brand name and assets have been transferred to the Japanese Group Nikko with the creation of Meccano SN. Meccano is still now launching lot of new products and lines every years. If the dimensions of the strips and the shape of the holes have not changed, Meccano has managed to keep its products developing a century long in order to continually meet children's expectations.

SOURCE

Credit Line

Donated through the Australian Government's Cultural Gifts Program in memory of Associate Professor Allan Bromley, 2010

Acquisition Date

20 January 2010

Copyright for the above image is held by the Powerhouse and may be subject to third-party copyright restrictions. Please submit an Image Licensing Enquiry for information regarding reproduction, copyright and fees. Text is released under Attribution-Non Commercial-No Derivative licence.

Image Licensing Enquiry

Object Enquiry