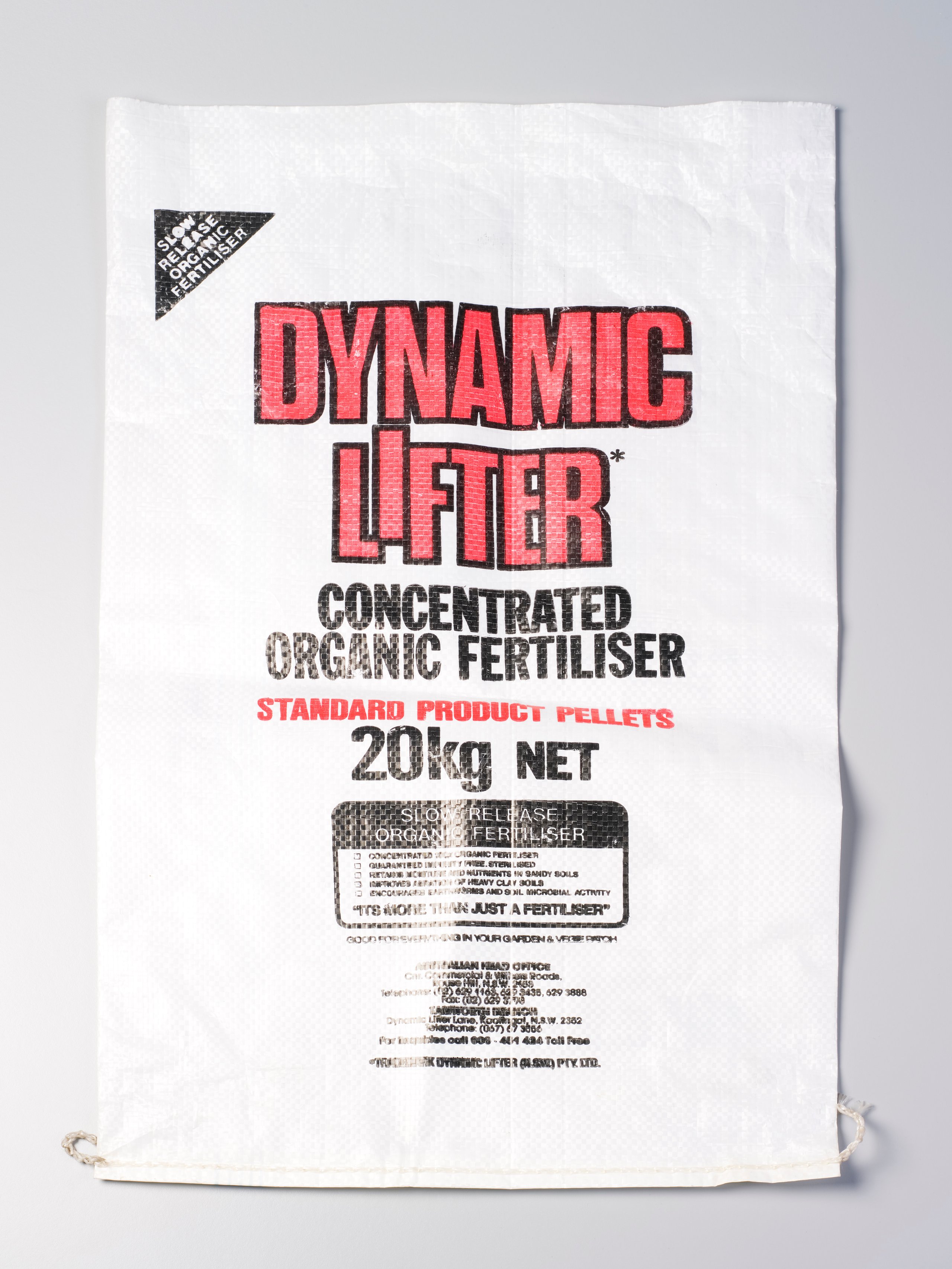

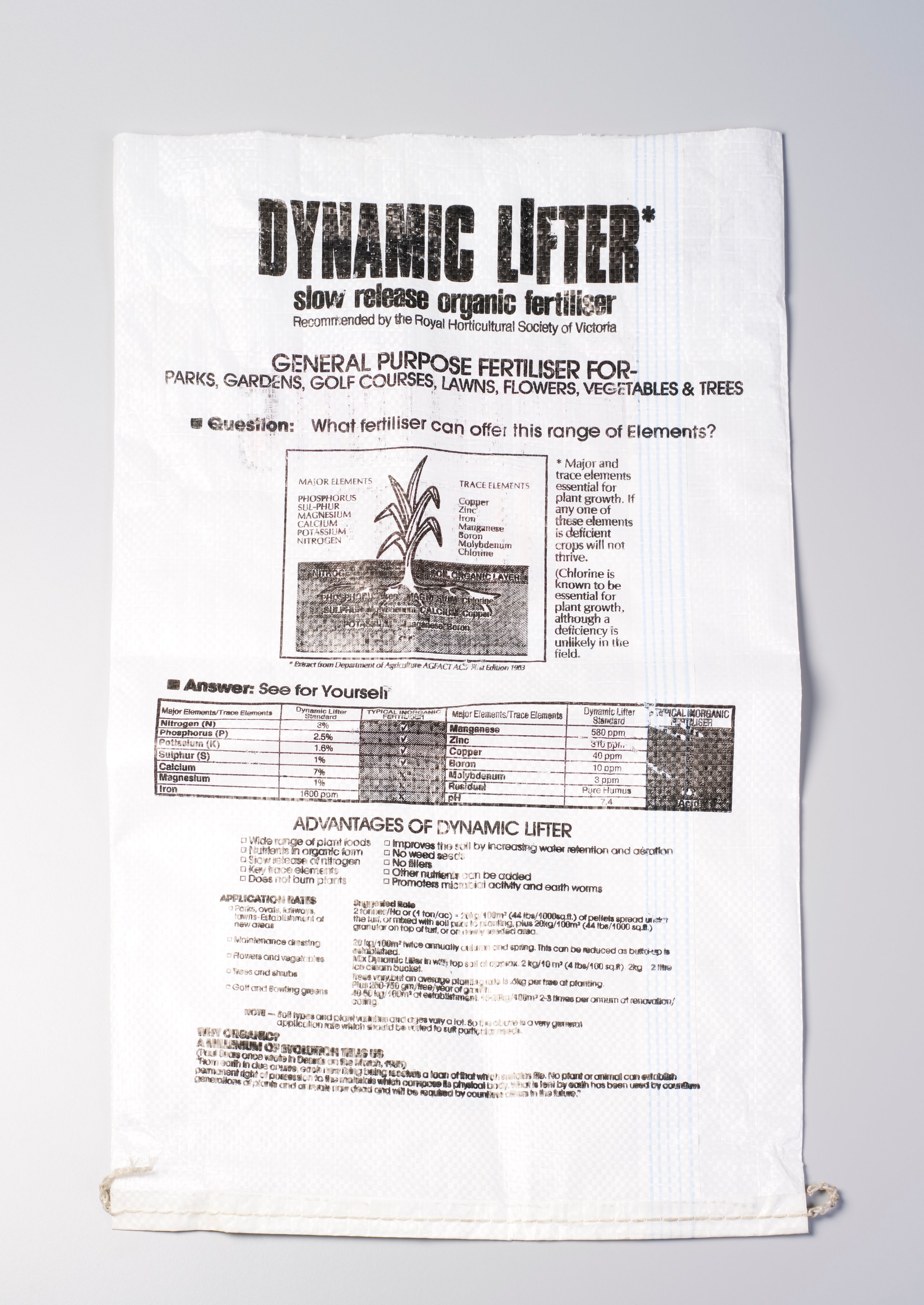

Woven polypropylene sack for Dynamic Lifter Fertiliser

Object No. 2006/106/1

Polypropylene is one of the most versatile and widely-used plastics available. Because of its strength and imperviousness to chemical attack, it is highly suited for the task of bulk packaging and mass distribution of an organic product like Dynamic Lifter. Polypropylene is widely used for the packaging of food and other organic products. In 1969 Norm Jennings realised that while chooks couldn't lay golden eggs, the stuff at the bottom of the cage was almost as good. It took another 15 years to work out ways to convert chook poo into Dynamic Lifter, a fertiliser that's easy to package, transport and use. To keep the droppings as dry as possible, he redesigned the birds' drinking trays to stop water from splashing onto the floor. He then used his engineering skills to develop machines to cure and sterilise the droppings and turn them into pellets, and that's the secret of Dynamic Lifter's international success. The catchy name was devised by Norm's wife and business partner, Nadia. The company negotiated agreements with poultry farmers in the region around each of the factories. In return for a contract to buy chicken droppings, the company installed its patented equipment in the farmer's sheds. Farmers benefit from the arrangement because Dynamic Lifter's drinking system for chickens keeps the manure dry and eliminates pollution and blowfly problems. The company collects manure from each of the farms on a regular basis and trucks it to the factory site to be cured and processed. Field trials in the 1970s demonstrated the outstanding success of Dynamic Lifter, and it was sold in bulk to farmers and orchardists. In the late 1980s bagged pellets began selling in supermarkets and plant nurseries to home gardeners. Dynamic Lifter is made under licence in the USA and exported from Australian factories to Asia, Europe and the Middle East. In 1995, the Jennings sold their technology and rights to Dynamic Lifter for $18.8 million.

Loading...

Summary

Object Statement

Packaging, 'Dynamic Lifter Concentrated Organic Fertiliser', woven polypropylene, maker unknown, used by Dynamic Lifter Pty Ltd, New South Wales, Australia, 1992

Physical Description

Packaging, 'Dynamic Lifter Concentrated Organic Fertiliser', woven polypropylene, maker unknown, used by Dynamic Lifter Pty Ltd, New South Wales, Australia, 1992 The sack is made of white woven polypropylene and printed with red and black ink. The bottom of the sack is turned up once and stitched with plastic thread.

DIMENSIONS

Width

455 mm

PRODUCTION

Notes

Poylpropylene is a biproduct of oil refining. It is a thermoplastic that is light, tough and resistant to heat and chemicals. It can be injection moulded, blow moulded and extruded. In order to make the woven material of this sack the plastic was extruded to produce film from which fibre tapes were then cut. Those tapes were subsequently woven into fabric. In 1969 Norm Jennings realised that while chooks couldn't lay golden eggs, the stuff at the bottom of the cage was almost as good. It took another 15 years to work out ways to convert chook poo into Dynamic Lifter, a fertiliser that's easy to package, transport and use. To keep the droppings as dry as possible, he redesigned the birds' drinking trays to stop water from splashing onto the floor. He then used his engineering skills to develop machines to cure and sterilise the droppings and turn them into pellets, and that's the secret of Dynamic Lifter's international success. The catchy name was devised by Norm's wife and business partner, Nadia. The company negotiated agreements with poultry farmers in the region around each of the factories. In return for a contract to buy chicken droppings, the company installed its patented equipment in the farmer's sheds. Farmers benefit from the arrangement because Dynamic Lifter's drinking system for chickens keeps the manure dry and eliminates pollution and blowfly problems. The company collects manure from each of the farms on a regular basis and trucks it to the factory site to be cured and processed. Field trials in the 1970s demonstrated the outstanding success of Dynamic Lifter, and it was sold in bulk to farmers and orchardists. In the late 1980s bagged pellets began selling in supermarkets and plant nurseries to home gardeners. Dynamic Lifter is made under licence in the USA and exported from Australian factories to Asia, Europe and the Middle East. In 1995, the Jennings sold their technology and rights to Dynamic Lifter for $18.8 million.

HISTORY

Notes

The sack was produced and printed for Dynamic Lifter Fertilisers Pty Limited. It was given to the Powerhouse Museum as an example of the packaging used for bulk distribution of Dynamic Lifter Fertiliser in 1992. The manufacturer of the sack is not recorded. Dynamic Lifter fertiliser was released onto the market in the late 1970s. The product is the result of two innovations by Norm Jennings. The first was a drinking system for intensively-farmed battery chickens that prevents the animals from spilling water onto manure below their cages. The second was a system for curing and compressing the manure into pellets that are easy to package, transport and spread onto a garden or paddock. It took Norm Jennings 15 years to develop Dynamic Lifter. The catchy name was devised by Norm's wife and business partner, Nadia. The company negotiated agreements with poultry farmers in the region around each of its factories. In return for a contract to buy chicken droppings, the company installed its patented equipment in a farmer's sheds. Farmers benefited from the arrangement because Dynamic Lifter's drinking system for chickens keeps the manure dry and eliminates pollution and blowfly problems. The company collects manure from each of the farms on a regular basis and trucks it to the factory site to be cured and processed. Field trials in the 1970s demonstrated the outstanding success of Dynamic Lifter, and it was sold in bulk to farmers and orchardists. In the late 1980s bagged pellets began selling in supermarkets and plant nurseries to home gardeners. Dynamic Lifter is made under licence in the USA and exported from Australian factories to Asia, Europe and the Middle East. In 1995, the Jennings sold their technology and rights to Yates Ltd which now manufactures and sells the Dynamic Lifter product.

SOURCE

Credit Line

Gift of Norm and Nadia Jennings, 2006

Acquisition Date

9 August 2006

Copyright for the above image is held by the Powerhouse and may be subject to third-party copyright restrictions. Please submit an Image Licensing Enquiry for information regarding reproduction, copyright and fees. Text is released under Attribution-Non Commercial-No Derivative licence.

Image Licensing Enquiry

Object Enquiry