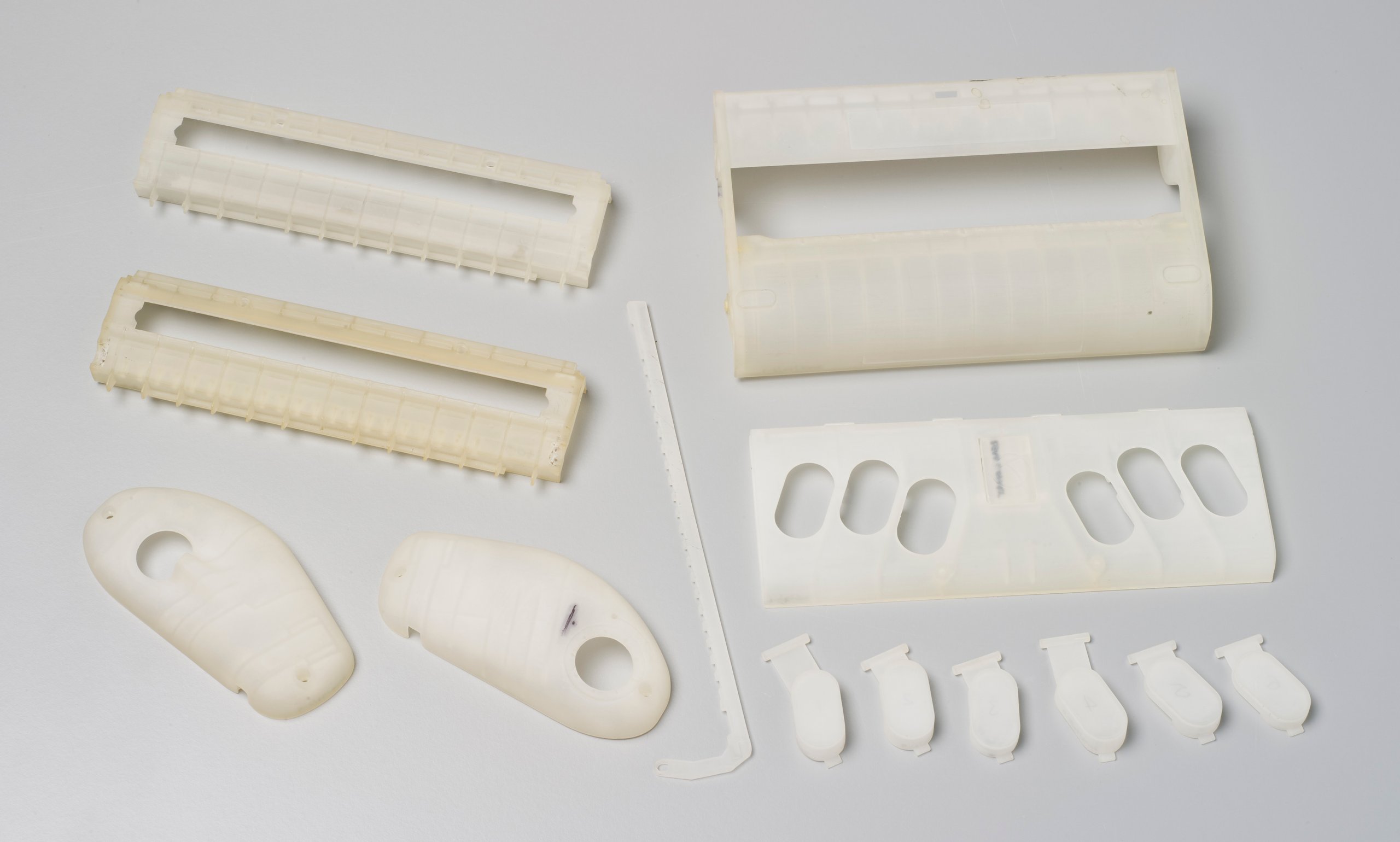

Prototype components for 'Jot A Dot' portable Braille writer

Object No. 2006/54/2

This prototype was made during the design and development process for the Jot A Dot portable Braille writer. The Jot A Dot is the blind person's equivalent of a notebook and pen. It is a small plastic Braille writer designed for making quick notes in Braille. Unlike other conventional Braille writers it is lightweight and easily portable. The full alphabet is achieved through hitting various combinations of the six keys. The Jot A Dot enables regular braille writing from the left hand side of the page to the right hand side of the page, which is a major advance in manual Braille writing. The user can read as they write by turning the Jot A Dot over and reading the Braille just typed on the underside of the device. Cell and line indicators give instant feedback on the location of the embossing head. This prototype is an example of one of the earliest and most widely used rapid prototyping techniques, stereolithography. First developed in the 1980s, stereolithography builds plastic parts or objects a layer at a time by tracing a laser beam on the surface of a vat of liquid photopolymer, forming a complete three dimensional object after many layers are formed. Rapid prototyping enables designers to quickly test their ideas in three dimensions and refine their ideas before they are presented to the tool maker or manufacturer. The Jot A Dot was developed by Quantum Technology, an Australian company specialising in the development, manufacture and distribution of technology solutions for people with vision impairment. The company's most significant product, the Mountbatten Brailler, was released in 1991 and was the world's first electronic, battery operated braille writer. The Jot A Dot represents the continued innovation by Quantum in developing products for the niche market of enabling technologies for people who are blind or vision impaired. The portability and low cost of the Jot A Dot makes it ideal for use in developing countries as an educational aid.

Loading...

Summary

Object Statement

Prototype components (13), for 'Jot A Dot' portable Braille writer, plastic photopolymer / metal, designed and made by Quantum Technology Pty Ltd, Rydalmere, New South Wales, Australia, 1997-2006

Physical Description

Prototype components (13), for 'Jot A Dot' portable Braille writer, plastic photopolymer / metal, designed and made by Quantum Technology Pty Ltd, Rydalmere, New South Wales, Australia, 1997-2006 Transluscent plastic parts for Jot A Dot portable Braille writer including the external housings, keys, and internal components. Some parts have been annotated in ink.

PRODUCTION

Notes

The Jot a Dot prototypes were designed and made by Quantum Technology at Rydalmere, New South Wales, between 1997 and 2005. The prototype was made during the design and development process for the Jot A Dot portable Braille writer. It was made from photopolymer using stereolithography rapid prototyping (SLA). Stereolithography uses data from a 3D computer model to build plastic parts or objects a layer at a time by tracing a laser beam on the surface of a vat of liquid photopolymer. This material quickly solidifies wherever the laser beam strikes the surface of the liquid. Once a layer is completely traced, it is lowered a small distance into the vat and the second layer is traced on top of the first. The self-adhesive property of the material causes the layers to bond to one another and eventually form a complete three dimensional object after many layers are formed. The idea for the Jot A Dot began in 1987 with a student project at Quantum Technology, but was not pursued because Quantum was busy developing and launching the Mountbatten Brailler around 1990. The six key design used on the Jot A Dot was first used by Quantum on the Mountbatten Brailler. The full alphabet is achieved through various combinations of hitting the keys. For over ten years a number of different people at Quantum worked on the idea for a simple, portable, mechanical device for writing Braille. Around 1997 more effort began to develop the Jot A Dot idea into a marketable product. The external form of the device resulted from the need to incorporate an internal paper roll and pin head components. Early prototypes were made using stereolithography (SLA) technology and used to test the design. The action of the brailler is based on the mechanism of a simple hole punch. The Jot A Dot enables regular braille writing from the left hand side of the page to the right hand side. The keys have been shaped to cater to the widest possible hand size and shape, and are based on sound ergonomic principle. The user can read as they write, by turning the Jot a Dot over and reading the Braille just typed on the underside of the device. The Jot a Dot includes an inbuilt reading stand, which keeps it stable when resting on hard surfaces. The Jot a Dot has high contrast colours and uses standard paper. Jot a Dot enables regular Braille writing from the left hand side of the page to the right, a major advance in simple manual Braille writing. It has both line and cell indicators. The cell indicator shows the position of the embossing head on the line. The line indicator gives instant feedback on which line you are writing. This means that if you need to go back to something you can ensure it is lined up properly on the Jot-A-Dot's typing row. The Braille is formed by the six pins located on the pin head. When the keys are depressed the corresponding pins in the head press into the die, embossing the paper to create a Braille cell. The head then moves along the row to the next cell, driven by the internal spring mechanism. The Jot A Dot is a one-piece construction, which means there are no parts that can be lost. It weighs 350g, so it's easy to carry. The device was assembled by Quantum Technology in Rydalmere from locally made parts. Achieving the required tolerances and dimensions of the plastic parts was a challenge in the initial stages of production. Specifications: Dimensions: 20.5 x 11 x 5.5 cm. Weight: 350g. Paper: Use normal photocopy paper(80 GSM Bond or 20lb). Fits A5 and A6 paper sizes. Braille: 20 cells of braille per line.

HISTORY

Notes

It is unknown how these prototype parts have been used. These parts were not all designed to fit together to form one device. These prototypes are typically disposed of once the project is complete. Quantum Technology is an Australian company specialising in the development, manufacture and distribution of technology solutions for people with vision impairment. The company was formed in 1976 by Jeremy Miller and Mike Ridley operating out of the garage of Jeremy's house in Epping. Quantum began as an electronic development consultancy involved in the areas of design, research and development and small scale manufacture. In 1986 Tim Connell was appointed as a Director along with Roy Middleton. In 1988 Tim Connell became Managing Director and was still in this position in 2006. Quantum's first product was the Speakwriter, a talking typewriter; the first such device produced anywhere in the world. A second product, the Braille 'n Print was developed by an Australian inventor. The Braille 'n Print is now used in 14 countries around the world and remains a vital tool in the education of blind children. In 1991, Quantum released the Mountbatten Brailler, arguably one of the most important developments in braille writing technology in the last 30 years. The Mountbatten Brailler is the world's first electronic, battery operated braille writer. In 1993, it was awarded the British Design Award, a rare achievement for an Australian product. Quantum has continued to develop the Mountbatten, drawing on many years experience in software and hardware design. In 1992, Quantum released the Nomad II, a system enabling blind children and adults to access graphical information such as maps, pictures and diagrams. Nomad II remains at the forefront of technology solutions aimed at breaking the graphics barrier for the blind, and has been awarded the Technology Prize at the Autonomique Exhibition for Disability in France. In Australia Quantum is also active in the distribution and support of a wide variety of assistive technology products. Included in this range are products from Freedom Scientific, Tieman, Enhanced Vision Systems, GW Micro, Index and others.

SOURCE

Credit Line

Gift of Quantum Technology Pty Ltd, 2006

Acquisition Date

18 April 2006

Copyright for the above image is held by the Powerhouse and may be subject to third-party copyright restrictions. Please submit an Image Licensing Enquiry for information regarding reproduction, copyright and fees. Text is released under Attribution-Non Commercial-No Derivative licence.

Image Licensing Enquiry

Object Enquiry