'Koerstz Squatters' wool press

Object No. H9309

Wool presses have greatly influenced the Australian pastoral industry. The development of effective and efficient wool presses saved labour costs, increased the number of sheep that could be shorn on a farm, and increased the value of wool when it went to market. If wool was well-packed and pressed, it presented well in European markets and thus commanded a good price. Pressing also decreased the cost of transport because shipping space was charged by volume rather than weight. Prior to the development of mechanical presses, wool was baled by hand. It was a laborious process that required a number of farm workers. Wool was spade-pressed in boxes after being trampled down by foot. A layer of fleeces was squashed in a box, then a spade was used to squeeze more fleeces into gaps between fleeces and around the edges. Trampling and squeezing continued until there were 16 fleeces per bale. This type of pressing created lumpy and uneven bales. Screw presses followed but they were extremely time-consuming. Large lever presses that used horse or man-power became common in the 1840s. 'Travelling box' presses were introduced in the 1860s. There were many variations and most were too expensive for graziers of small flocks to buy. Those farmers would usually take their sheep to be shorn at larger properties. In the 1890s, Christian Koerstz, in business with Frederick Mason, designed and made cheap, efficient presses for small landholders. They transformed the industry. The presses occupied little floorspace and could be operated by one man. By the 1930s about 12,000 small Koerstz Selectors' and Homestead Lessees' presses had been sold around Australia and the world. By 1910 the heavier 'Squatter' press was standard equipment in most big shearing sheds. Little is known of the provenance of the Powerhouse Museum's Koerstz wool press, however it was donated to the Museum by F.W. Hughes Pty Ltd, a leading wool and textile company established in NSW in 1915.

Loading...

Summary

Object Statement

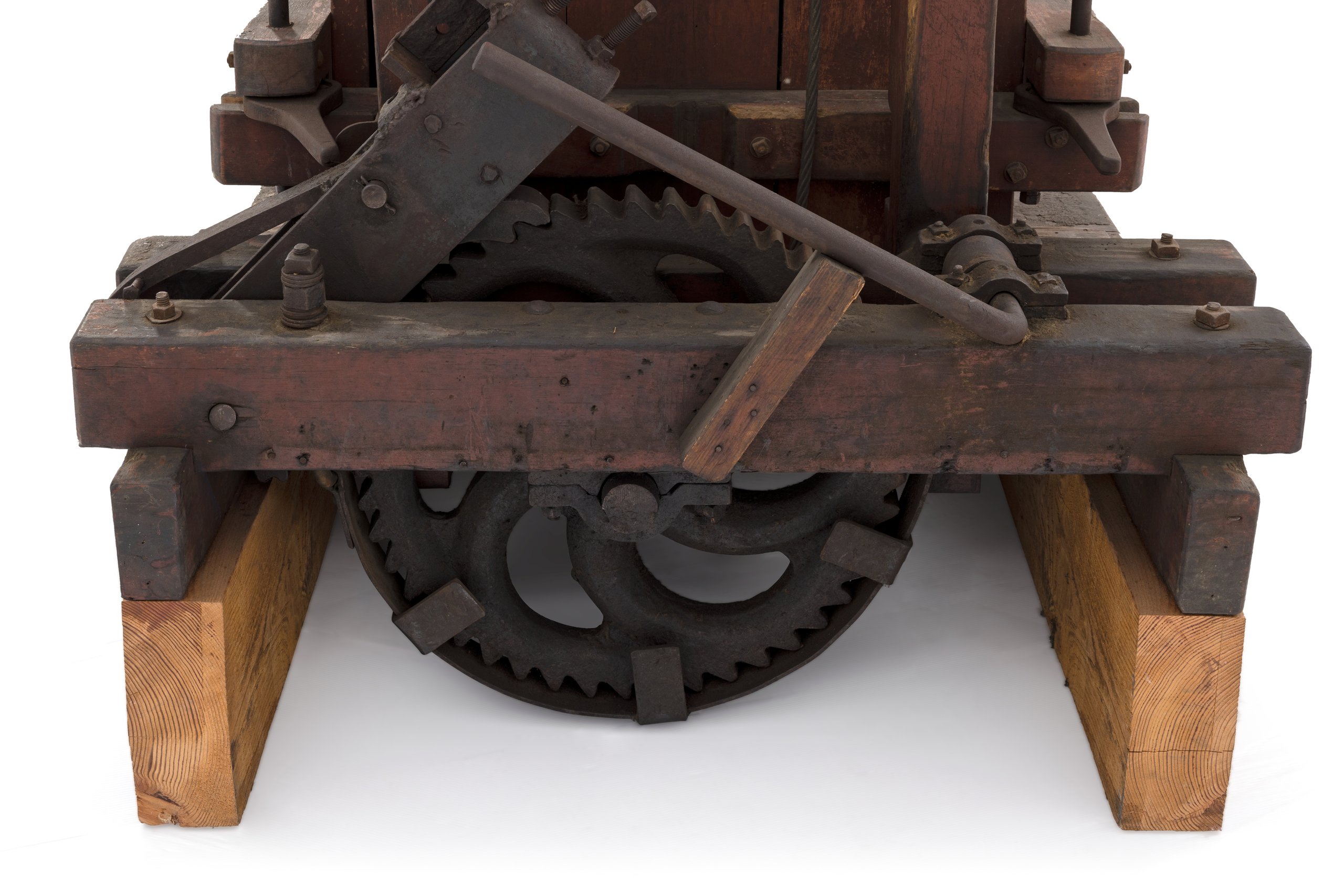

Wool press, 'Koerstz Squatters', wood / iron, made by C Koerstz Manufacturer, Waterloo, New South Wales, Australia, c. 1890

Physical Description

Full size wool press constructed from wooden planks with metal support hoops and a compression mechanism. The wool press has an upright square central barrel divided into three sections. The lower section has a swing out door and white text stencilled onto the door. There is a large metal and wooden handle mounted onto the right side of the press.

DIMENSIONS

Height

2810 mm

Width

1620 mm

Depth

1170 mm

Weight

850 kg

PRODUCTION

Notes

This wool press was made by C Koerstz in Waterloo, Sydney, Australia c 1890.

SOURCE

Credit Line

Gift of F W Hughes Pty Ltd, 1977

Acquisition Date

14 February 1977

Copyright for the above image is held by the Powerhouse and may be subject to third-party copyright restrictions. Please submit an Image Licensing Enquiry for information regarding reproduction, copyright and fees. Text is released under Attribution-Non Commercial-No Derivative licence.

Image Licensing Enquiry

Object Enquiry