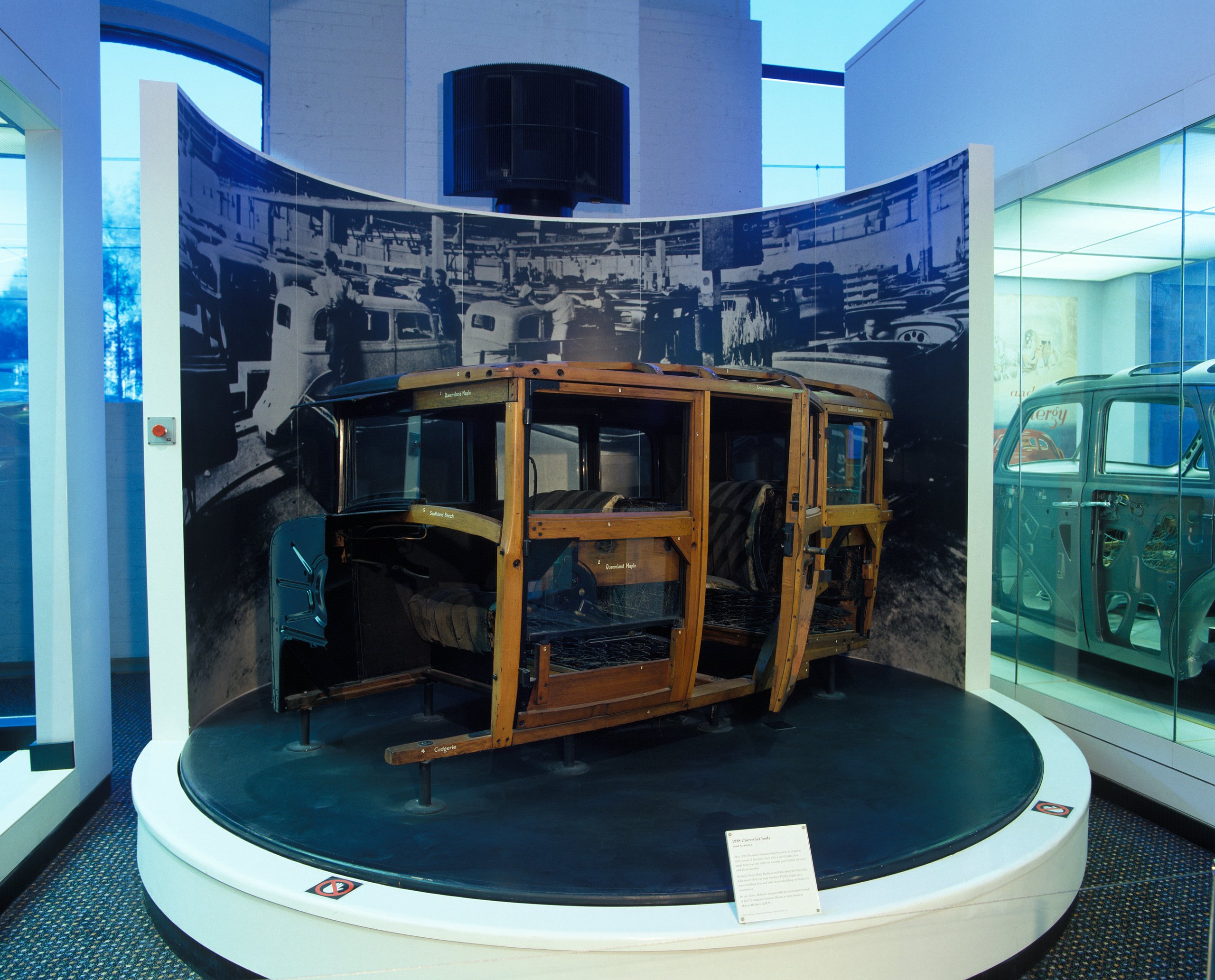

Full size sectioned Chrysler automobile body

Object No. H3457

This is a timber-framed, steel skinned sedan car body from a 1928 Chrysler. It was made and sectioned by the famous Australian firm, Holden's Motor Body Builders Ltd of Woodville, South Australia, to show its construction and the various types of timbers used at the time. These included Queensland maple, Pacific maple, cudgerie and southland beech. By the late 1920s some 200 pieces of timber, bolted, screwed and glued together, were required to build just one car body. By the mid-1930s cars became more streamlined and in 1937 Holden's (by then General Motors-Holden's Limited or GMH) released the uni-steel turret top body, the first Australian-made all-steel car body. This was a huge advance on the timer bodies as it was only constructed of four pieces of pre-fabricated steel shaped by giant presses and spot-welded together. These steel sections formed a stronger, lighter and much cheaper body than the complex timber ones. The work required for the construction of a timber car body like this Chrysler was much like that needed for an intricate piece of furniture or a horse-drawn vehicle. Many of the early motor body builders were previously coachbuilders.

Loading...

Summary

Object Statement

Sectioned automobile body, sedan, full size, Chevrolet, timber / metal, made by Holden Motor Body Builders Ltd, Woodville, South Australia, Australia, 1928-1929

Physical Description

Sectioned automobile body, sedan, full size, Chevrolet, timber / metal, made by Holden Motor Body Builders Ltd, Woodville, South Australia, Australia, 1928-1929 Motor body sectioned to show framework, seats and roof and the types of timber used: coachwood, Queensland maple, Pacific maple, cudgerie, Southland beech, Alpine ash, Japanese beech and Oregon.

DIMENSIONS

Height

1300 mm

Width

1600 mm

PRODUCTION

Notes

Wooden motor bodies were built to travel thousands of miles without being shaken to bits, to be left out in the rain and changing temperatures without becoming warped and losing their smooth finish and colour. Timber had to be seasoned so that it would not warp as it dried out. This was done artificially in kilns and then stored for a period. From storage it was taken to the milling bay where it was cut to certain sizes and all knots and defects cut out. The timber originally used was English ash, however Australian timbers were found to be just as good, if not better, than the imported wood which was hard to obtain during the first World War. There were around 200 pieces of timber used in the manufacture of a Holden body, excluding interior trimming. Then followed the setting-up process in which the finished wooden parts were placed in large jigs/moveable platforms made especially for each model of car body. These pieces were then screwed, bolted and/or glued together. Originally this was with white lead as it was waterproof and early glues were not. The lower parts of the body were framed up first. The side pillars were erected next, followed by the wheel arch, front cross-framing, the roof framing and then the back frame. The driver's seating area and side doors were left till last. While the body was being set up braces were used to keep the timbers in place, giving the body strength and rigidity. Pannelling and seat construction were generally constructed separately and then placed inside the car once the timber frame was completed. The outside of the body was then covered with thin steel panels that were pressed by mechanical presses. These panels were originally hand beaten on sand-filled sacks before presses were used. Welding, which had only been used industrially since 1903, was used in some cases to join the metal panels together, which were then polished to a smooth finish for painting. Paint was then sprayed onto the panel by primitive spray guns. Further trimmings were added to complete the body, such as polished wood, panelling, door locks, striking plates and silencers. Some trim such as interior doorhandles were made of a plastic called "fibro-monolithe", which could be applied like a plaster that dried hard. The 1929 Chrysler appeared with new slender profile radiators and long sweeping lines. It also had internal expanding brakes and their body styling and ribbon-type radiator shells were widely imitated in Europe over the next few years. Chrysler sold 98,000 cars in America in 1929, whilst Holden produced bodies for 626 Chyrslers in Australia that year. The rear quarter window handles are actually Chevrolet parts for the Chevrolet models of 1929. Such parts were generally interchanged by body builders. The body measure 2.7m long by 1.5m wide and is 1.3m high.

HISTORY

Notes

This motor body was sectioned and donated to the Museum by the makers, Holden's Motor Body Builders Ltd, in 1930. In 1854 James Alexander Holden set up a leather and saddlery business in Adelaide. His son, H.J. Holden continued the business after J.A. Holden died in 1887. The firm gradually expanded and in the early 1900s he asked H.A. Frost to join the firm. In 1910 Holden and Frost expanded into the trimming of motor vehicles, when they hired a Mr R.F. Stevenson to start a motor trimming department - "Holdfast Trimmings". Stevenson's son joined the firm as a young lad three years later, and in 1915 they both left to start their own business of spring making. The same company, FRS Springs continues to supply GMH with seat springs today (1983). It is interesting to note that a young Victorian schoolboy, also named R.H. Holden, built a primitive steam powered vehicle in Geelong in 1911. In 1914, H.J. Holden took an individual oreder for a custom body to suit a Lancia chassis which was owned by a publican. One custom body led to another. Holden and Frost also built batches of motorcycle sidecars and model T Ford bodies. An embargo on importing motor bodies was imposed by the Australian Government in 1917 due to the lack of space on ships as a result of the First World War. Australian industry at that time was not established to make the number of engines, transmissions and chassis needed, but Australian coachbuilders were able to cope with the manufacture of motor vehicle bodies. These, the Government decreed had to be made in Australia to save valuable shipping space. With the end of the war the Government continued to assist the motor body building industry by raising duties payable on imported bodies. These taxes when added to the cost of imported bodies were so high that it was no longer profitable to bring bodies or even panels into Australia. A Mr Cheny of the Cheney Motor Co of Adelaide (later the Waymouth Motor Co) who imported Dodge cars realised that car bodies would need to made in Australian and Mr Holden in 1917 if his firm could do the work. Mr Holden agreed and soon Holden and Frost were looking at orders for 5,000 bodies for Dodge and Buicks for the next five years. Holden at the time did not have the facilities for the production of so many motor bodies. He solved the problem by buying all the available shares in F.T. Hack Ltd, a body building shop in King William Street, Adelaide, S.A. A prototype motor body exhibited at a Dodge distributors conference in Sydney brought orders rolling in. On 25/2/1919 Holden officially formed a new company - Holden's Motor Body Builders - and was run from the King William Street factory, it was incorporated on 1/5/1920. The Holden and Frost firm was left to the horse and carriage business and eventually sold in 1925. In 1921 Tarrant Motors also placed orders for Holden bodies for some of their cars. A minor depression of 1921 slowed chassis imports to almost nil for some months. To supplement lost body production, Holden's accepted an order to build railway carriages for the S.A. Railways. In 1923, Edward Holden toured the United States and Europe. This tour sowed the seeds for the future amalgamation of General Motors Australia and Holden's Motor Body Builder's Ltd. In the same year Holden's also purchased 10 then a further 12 acres at Woodville, S.A. due to increased production and the fact that General Motors announced they were going to use Holden's as sole body builder suppliers for their motor bodies, (10/12/1923). This year 17,000 bodies were produced as compared to 6,621 in 1922 (with 35,892 bodies being produced in 1934). Holden's were now producing 50% of all motor bodies in Australia. GM engineering people were sent over from America to assist in body production and a hydraulic press was installed for a more uniform and smoother panel surface. Between 1924-26 Holden's also made some 59 "W" class trams for Melbourne. Some of these still run today. H.J. Holden died in 1926 and the firm continued to directed by Edward Holden. In the same year GM established themselves in Australia as General Motors (Australia) Pty. Ltd. and intended to set up their own plant in Melbourne. However the GM overseas executive decided to use Holden's. Holden's was being affected by the depression of 1930 and made fruit cases to replace lost body business. In 1931 General Motors purchased Holden's at a cost of 1,111,600 pounds and established General Motors Holden. This firm was managed by Laurence H. Hartnett. At the time it was the largest body shop in the British Empire, excluding Canada, employing 2,600 people and able to produce 35,000 bodies annually. General Motors pursued a policy of purchasing Australian materials where possible. The chassis and engine were imported in disassembled form and were then assembled in one of the five General Motors plants in the major states. In 1934 General Motors Holden's departed from the traditional United States body styles by producing a Chevrolet coupe utility. Following the design of the first ute ever built, this being by Ford (Australia). In 1936 further Government tarrifs and restrictions were introduced to encourage Australian motor industries. These included an establishement of an engine bounty, restricted chassis imports and local manufacturing to be restricted to companies having 50% Australian ownership. An Industries Commission suggested that Australian manufacturers should be encouraged to produce an all Australian motor car. GMH put forward a proposal that was accepted in 1946 and in 1948 the first Holden rolled off the assembly line. Since then over 3 million Holdens of various models have been sold in Australia and overseas. Other contemporary motor body builders included T.J. Richards in Adelaide who went on to become part of the giant factories of Chrysler Limited in South Australia. J.A. Lawton and Son Ltd. went on to specialise in hand made non-standard body work for such vehicles as fire engines, semi-trailers and other industrial vehicles. Ford built their own plant at Geelong, Victoria.

SOURCE

Credit Line

Gift of Holden Motor Body Builders Ltd, 1930

Acquisition Date

25 June 1930

Copyright for the above image is held by the Powerhouse and may be subject to third-party copyright restrictions. Please submit an Image Licensing Enquiry for information regarding reproduction, copyright and fees. Text is released under Attribution-Non Commercial-No Derivative licence.

Image Licensing Enquiry

Object Enquiry