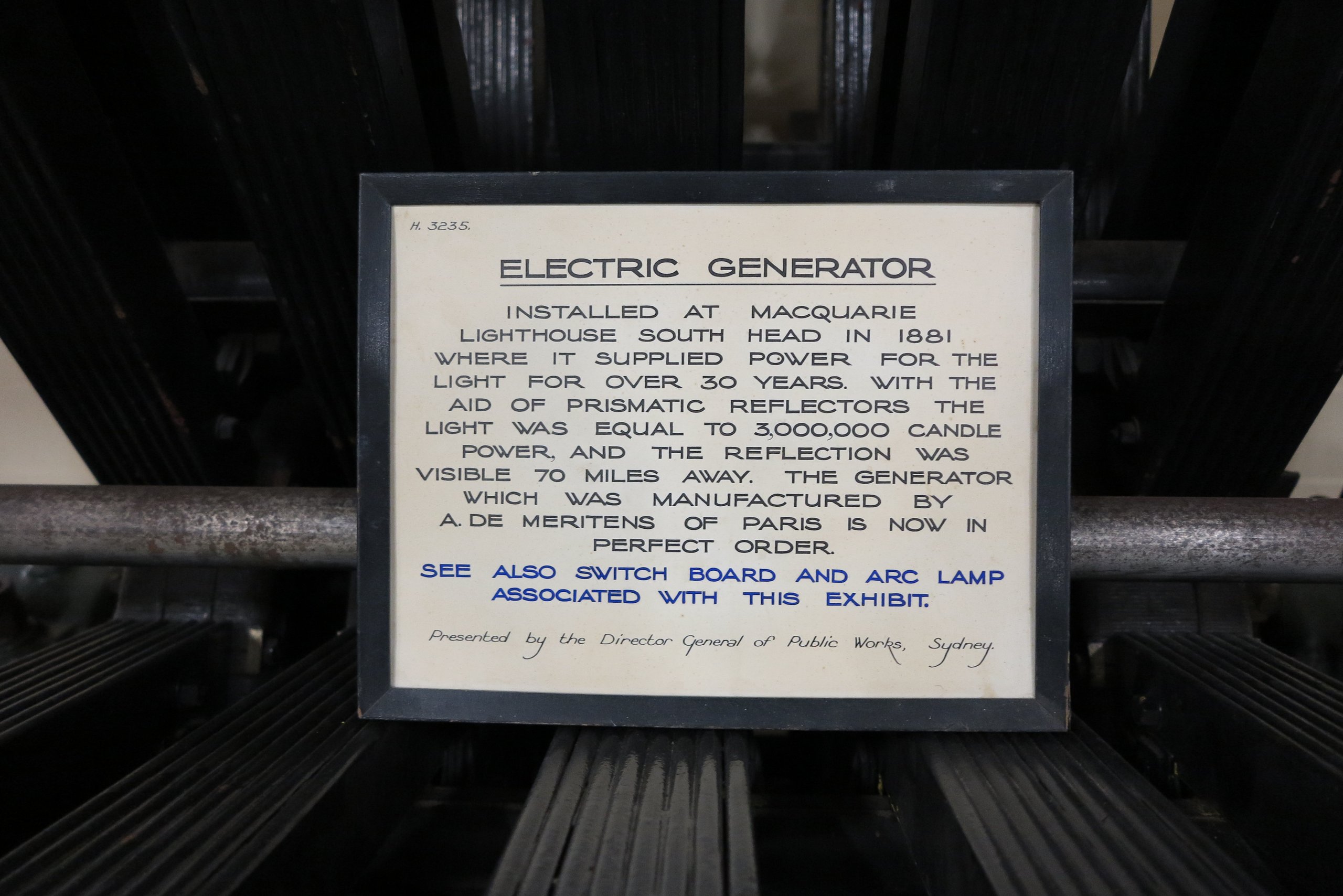

Electricity generator used at Macquarie Lighthouse

Object No. H3235

This is one of the earliest electricity generators used in Australia for a practical purpose. Previously, electricity had been supplied by batteries (for electroplating metal goods, printing by the electrotype process, or ringing bells) and by batteries or small hand-cranked magnetos (for sending messages by telegraph or telephone). In 1883 this magneto-electric alternator came into service, alongside a second identical machine, at Sydney's second Macquarie Lighthouse, powering an arc lamp whose light was reflected out to sea by a large lens. The 1880s also saw the importation of other electricity generators for lighting indoor and outdoor spaces in cities and towns, and for safely lighting underground mines. Several systems and companies competed for business. Some used arc lights, while others used small incandescent light globes made by Swan in the UK or Edison in the USA. The history of the alternator reflects another type of competition: the long-running battle between oil, gas and electricity as means of lighting. The arc lamps it powered replaced the oil lamps that had shone from the original Macquarie Lighthouse since 1818. To save money, the new lighthouse was not run exclusively on electricity; the city's gas main having been extended to the site so the generators could be turned by gas engines, a pipe was built into the tower to feed a gas lamp on clear nights. An oil lamp was available in case the gas supply was interrupted. Again as a cost-cutting measure, the generators and arc lamps were decommissioned in 1912 in favour of an improved kerosene vapour lamp. Electricity finally won the battle in 1933, when the lighthouse was switched to mains-powered electric operation. Oersted in Denmark, Faraday in England, and Ampere in France developed the basic science that links electricity and magnetism. Pixii in France, Nollet in Belgium and Holmes in England, among others, developed magneto-electric technology. This alternator was made in Paris by Auguste de Meritens, whose machines were selected for use in French and British lighthouses. His innovations increased the current output and improved the smoothness of the voltage waveform, and his machines were acclaimed for their efficiency and reliability; one at the Lizard Lighthouse in Cornwall operated from 1881 to 1950. The alternator also represents the work of Chance Brothers of Birmingham, the contractor who made the Macquarie Lighthouse lens, its rotating pedestal and the lantern room that housed the lamp and lens. Chance Brothers selected the gas engines, alternators, switchboard and arc lamps for the lighthouse and sent all components as a package. The company's collaboration with Michael Faraday to improve optical glass gave it an edge that allowed it to equip many lighthouses around the world. Debbie Rudder and Noel Svensson References: Prof J. Tyndall, 'Popular Science Monthly', March 1879. (Popular Science March 1979 Google Books.) Lance Day & Ian McNeil, 'Biographical Dictionary of the History of Technology', p 483, Google Books 1998. 'Tariff of Lighthouse Apparatus, Lanterns and Towers, Constructed by Chance Bros & Co Ltd', Lighthouse Works, near Birmingham, 1908. (PHM Library Catalogue No F623 8942). P H Sydenham, 'Early Australian technology: important lighthouse electrical generating plant', General Engineering Transactions, The Institution of Engineers Australia, pp18 - 24, 1978. THE MACQUARIE NEW LIGHTHOUSE. (1882, January 17). The Sydney Morning Herald (NSW : 1842 - 1954), p. 3. Retrieved October 28, 2018, from http://nla.gov.au/nla.news-article13503133 THE NEW MACQUARIE LIGHTHOUSE. (1883, April 26). The Sydney Morning Herald (NSW : 1842 - 1954), p. 5. Retrieved October 25, 2018, from http://nla.gov.au/nla.news-article28373945

Loading...

Summary

Object Statement

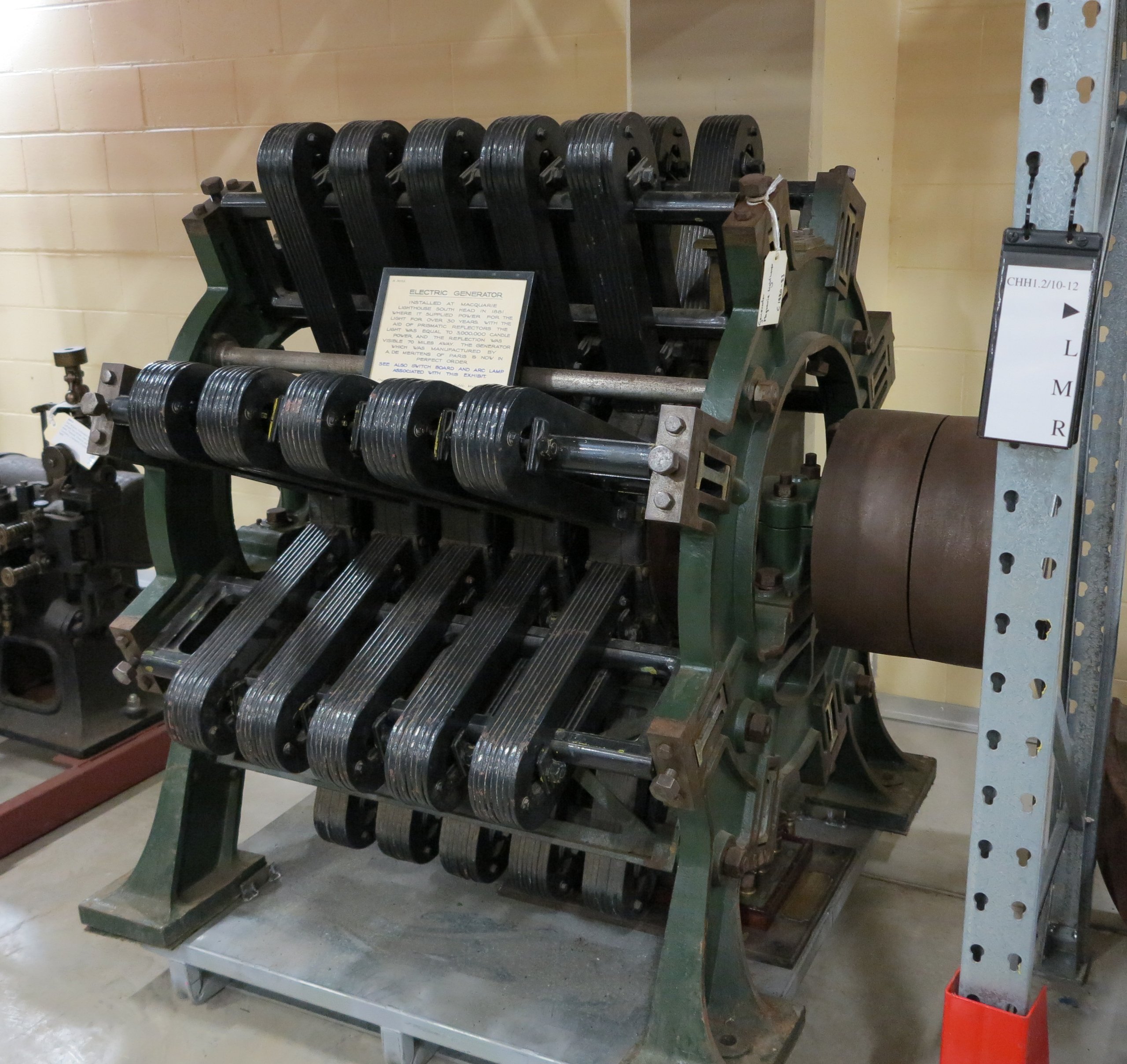

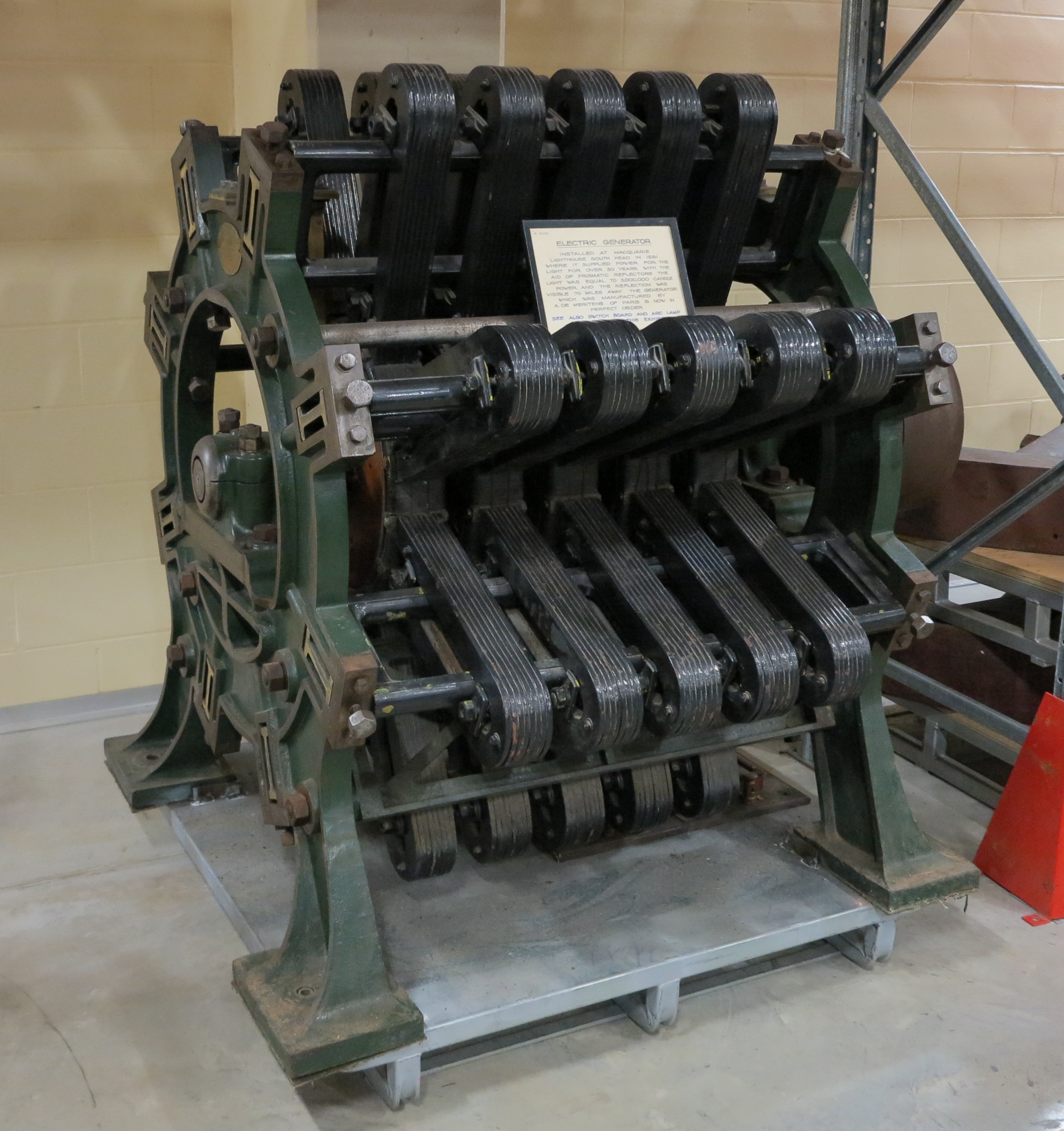

Magneto-electric generator, Magnéto-Electrique No. 16 G, alternating current, metal/wood/insulating fabric/paint, made by Auguste de Meritens, 44 Rue Boursault, Paris, France, 1880-1881, used in Macquarie Lighthouse, South Head, Sydney, New South Wales, Australia, 1883-1912

Physical Description

Five banks of eight radially disposed horse-shoe shaped permanent magnets are arranged uniformly along the length of the machine, with north and south poles alternating around the interior circumference of each bank. Each magnet is made from eight sheets of steel, cut to shape, permanently magnetised and clamped together. Each bank of magnets can be adjusted, radially, to bring them closer to the rotor windings. The rotor consists of five banks (to match the number of banks of magnets) of sixteen separate ring windings of insulated conducting wire carried on the periphery of spoked wheels, through which a single horizontal shaft runs. An alternating current is generated in the windings when the rotor turns within the magnetic field. The ends of the rotor are covered by wooden discs, and the conducting wires are attached to a pair of slip rings on the outer side of each wooden disc. Copper wire brushes adjacent to the slip rings collect the current, which is then conducted to terminals via bus-bars. In the lighthouse, cables connected these terminals to a switchboard (object H3236-2) mounted on a nearby wall. At one end of the horizontal shaft are two pulleys, which were driven by a belt from an 8 horsepower (6 kW) gas engine. The generator is classed as an alternator because it produced alternating current. Turning at 830 rpm, it generated 4.5 kW at 110 A. It powered a modified Serrin type arc lamp (object H3236-1) via the switchboard. The mass of the alternator is about 2.3 tonnes. The installation at Macquarie Lighthouse consisted of two de Meritens magneto-electric alternators driven by two Otto-Crossley 'Silent' gas engines, which were fuelled by coal gas from the city's mains, via an on-site gas holder. During foggy nights, one alternator supplied full power to an arc lamp with two thick carbon rods installed so it produced very bright light as electricity arced across the small gap between them. The other generator and engine were on stand-by, as were five other arc lamps. In hazy conditions, the engine was run at a lower speed to reduce the power supplied by the alternator, and an arc lamp with thin carbon rods was used. In clear weather, a gaslight burner replaced the arc lamp, and an oil lamp was kept on stand-by. This redundancy ensured that light was flashed out to sea to warn sailors regularly throughout every night, while using gas directly for lighting whenever possible improved the economics of the system.

PRODUCTION

Notes

Baron Auguste de Meritens (1834-1898) made this magneto-electric alternator in Paris in 1880 or 1881. Although he is best known for the design and manufacture of lighthouse generators, he also invented the first arc welding process and made equipment that was used to weld lead plates. In 1820 Danish professor Hans Oersted became the first person to observe that electric current creates a magnetic field. In 1831 English scientist Michael Faraday demonstrated that moving a magnet within a cylindrical coil of wire induces a current in the wire, and that rotating a metallic disc within a magnetic field induces a current in the disc. From his observations he formulated the Law of Electromagnetic Induction: that moving a conductor through a stationary magnetic field produces a voltage across the conductor. This work led to the development of useful electric motors and generators. In 1832 French instrument-maker Hippolyte Pixii built a hand-cranked alternator. In 1850 Belgian professor Floris Nollet patented a steam-driven alternator, thus initiating the era of large-scale generation of electricity powered by fossil fuels. Before that time, electricity was supplied by primary batteries or magnetos for uses with low power demand, such as the telegraph and electroplating. Nollet's concept was to use electricity to split water into hydrogen and oxygen, which would be recombined on the spot to create limelight. The British-French Compagnie de l'Alliance later improved on the design of Nollet's alternators and began making them for lighthouses and industrial purposes. These machines were composed of discs, built upon a central revolving shaft. Each disc was fitted at its outer edge with sixteen coils of wire, in which the current was generated by the inductive influence of permanent horse-shoe magnets arranged on fixed frames round the circles in which the coils revolved. Each machine had four or more discs, and a corresponding number of coils and magnets. Working with the Alliance and later on his own, English engineer Frederick Holmes patented and made generators for producing arc light in British lighthouses. He realised that arc lighting would be more convenient than limelight. He was advised by Michael Faraday, who developed methods for testing arc lighting at an experimental lighthouse in London. Auguste de Meritens improved on the design of the Alliance machines by using distributed rotor windings in place of individual bobbins. (French Patent 123766 April 1878, British Patent 3658 September 1878). This improved the voltage waveform and achieved continuous output. He founded the firm of A de Meritens & Cie around 1881, but this generator is just signed with his name. De Meritens alternators are held by the Birmingham Science Museum and the Danish Technical Museum in Helsingor, and London Science Museum holds a Holmes machine. The machine in Birmingham, which was used at the Lizard Lighthouse in Cornwall from 1881 to 1950, is signed 'A de Meritens', but the later one in Helsingor bears the company name and notes that it won a gold medal at the 1881 Paris electrical exposition.

HISTORY

Notes

The most impressive electric lighting system in Australia before Macquarie Lighthouse was at Circular Quay in Sydney, where a steam-powered Brush dynamo housed in a shed on Bennelong Point was connected to arc lamps strung from there to the Mariners' Church, behind the current Overseas Passenger Terminal. From the first day of 1883 these lamps provided light for night-time wharf operations as well as for large numbers of people boarding or alighting from ferries. Chance Brothers was contracted to supply the lighting system and lantern room for the second Macquarie Lighthouse, which began working in 1883 on Sydney Harbour's South Head. The company acquired the alternator from de Meritens to help fulfil this contract. After testing the complete system at its works in Smethwick (near Birmingham UK), Chance Bros dispatched the lighthouse apparatus (engines, alternators, switchboard, arc lamps, Fresnel lens, rotating pedestal and lantern room) from London on 23 November 1881 on board the Royal Mail Steamer (RMS) Khedive. The shipment arrived in Sydney on 16 January 1882. The 1883 lighthouse was designed by NSW Colonial Architect James Barnet to closely resemble the original Francis Greenway building, which had operated from 1818. The original lighthouse was retained while the new one was erected and commissioned on an adjacent site, to ensure continuity of service to shipping. The system was first trialled on 24 Aug 1882. It was in service from 1 June 1883 until July 1912, when the arc lamps were replaced by Australian-designed high efficiency Schmidt-Ford kerosene vapour lamps, which had incandescent mantles. One of these lamps, which were already in service in other NSW lighthouses, had been used at Macquarie Lighthouse during a coal strike in 1910. The kerosene light was cheaper to run than the electric light, it did not need an engine driver or a reliable supply of coal gas, and it did not consume carbon rods or require their frequent replacement. In 1933 the lighthouse was converted to electric operation, using mains power. The alternator was donated to Sydney's Technological Museum in 1917, along with the switchboard and one of the arc lamps. H R Carleton of the New South Wales Public Works Department wrote an excellent description of the lighthouse that is reproduced in the 1987 book, 'Engineers and their works in New South Wales 1884-1914'. He noted that Macquarie Lighthouse was: 'situated immediately in the rear of the old lighthouse at South Head, of Port Jackson. The tower is 61 feet high from the ground to the lantern and is divided into four storeys. It is circular on the plan, 11.5 feet in diameter inside, built of sandstone, dressed both sides, designed to resemble as closely as possible the old lighthouse. The base of the tower, externally, is 23.5 feet square, to a height of 17 feet, above which it is circular, the walls being 4 feet thick near the bottom, tapering to 3 feet thick at the top. Bluestone gallery round lantern, with gun metal railing. Engine room, oil stores, and workrooms are provided in 2 one-storey wings, one on either side of tower and attached to same, the wings being each about 24 feet square, surmounted by domes constructed of woodwork and covered with lead. The engine room contains two 8 hp Crossley's gas engines, and two De Meritens magneto-electric machines, weighing 2.5 tons each. A gasholder, containing 4 or 5 days' supply, is also provided, connected with the mains of the Australian Gas Light Co.' 'The lighthouse cost 19,620 pounds to erect and its light was described as 1st order dioptric, holophotal, revolving white light, electric light, gas or oil; visible between N. by E. quarter and S. by E., showing a flash every minute and making a complete revolution in 16 minutes'. Chance Brothers and Company was founded in 1824. During 1832 the company became the first to adopt the cylinder method of producing sheet glass (see objects A2479 to A2497, stages in that process). In the 1850s one of its engineers collaborated with Michael Faraday to improve the quality of optical glass. Here Faraday (who is usually portrayed as a pure scientist) worked as an applied scientist, as he did when he tested lighthouse lenses at an experimental lighthouse built for him in London. The company became the largest British manufacturer of window and plate glass, lighthouse lenses and optical glasses. It supplied equipment to many lighthouses around the world, even shipping some complete prefabricated lighthouses. Some of its products are still at work today, even though its works closed in 1981. The lens used in conjunction with the alternator was based on an 1822 design by French engineer Augustine-Jean Fresnel that dramatically improved lighthouse illumination. Fresnel replaced multiple lamps and reflectors with a single lamp placed in the focal plane of a large beehive-shaped lens. This had a central panel of magnifying glasses surrounded by concentric rings of prisms and mirrors angled to gather light and direct it towards the focal plane, where it was intensified and projected seaward. The Chance Bros lantern room (also called a lantern) at Macquarie Lighthouse enclosed the arc light and Fresnel lens and protected them from the weather. It was made of glass panels fixed in a diagonal steel lattice, forming a cylinder capped by a hemispherical dome surmounted by a wind vane. The diagonal lattice was chosen to produce the least interference with the light's function. Checking the wind vane allowed the keeper to open the appropriate vents to ensure a draught of fresh air entered the lantern room and carried away the hot gaseous products of arcing or combustion.

SOURCE

Acquisition Date

20 July 1917

Copyright for the above image is held by the Powerhouse and may be subject to third-party copyright restrictions. Please submit an Image Licensing Enquiry for information regarding reproduction, copyright and fees. Text is released under Attribution-Non Commercial-No Derivative licence.

Image Licensing Enquiry

Object Enquiry