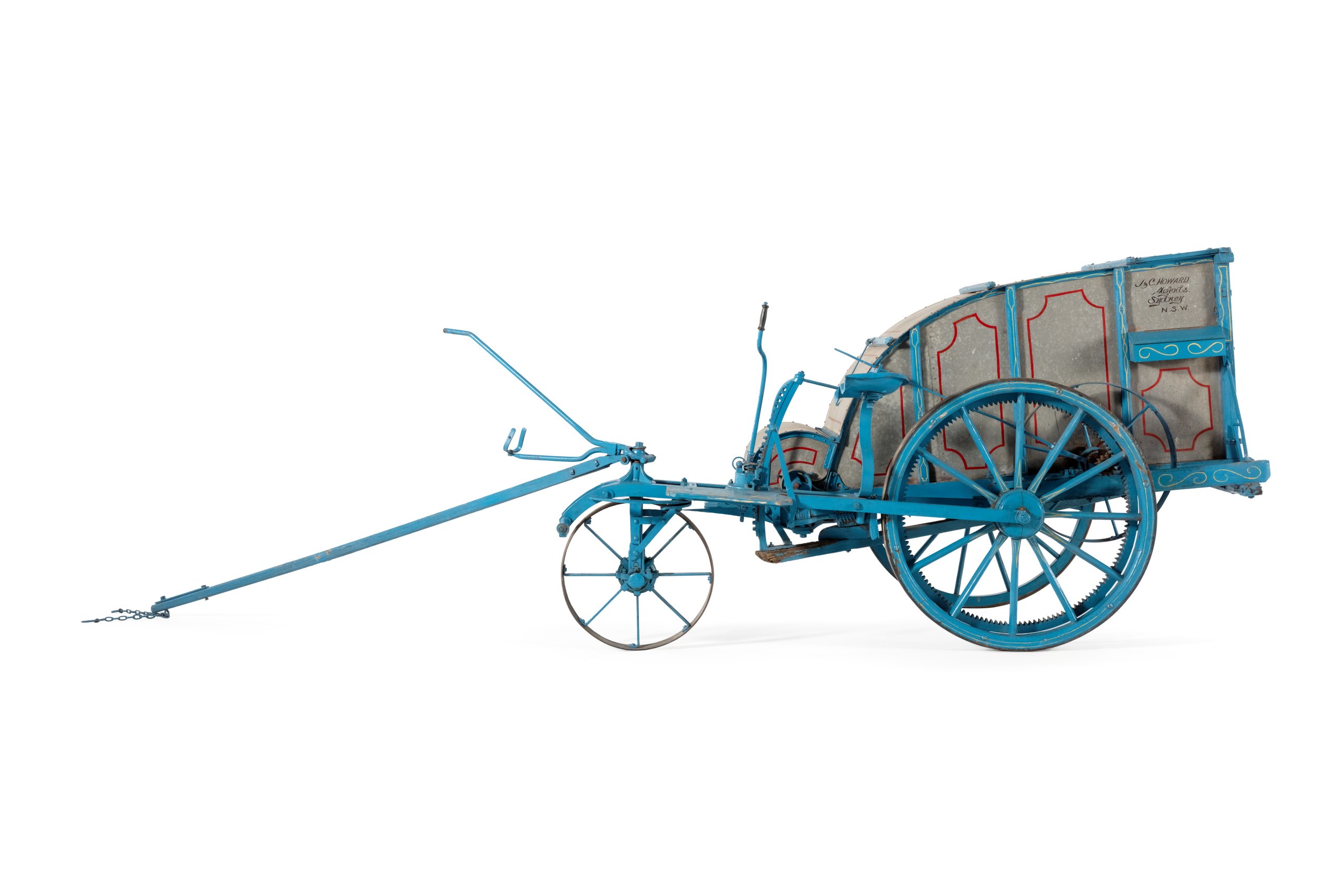

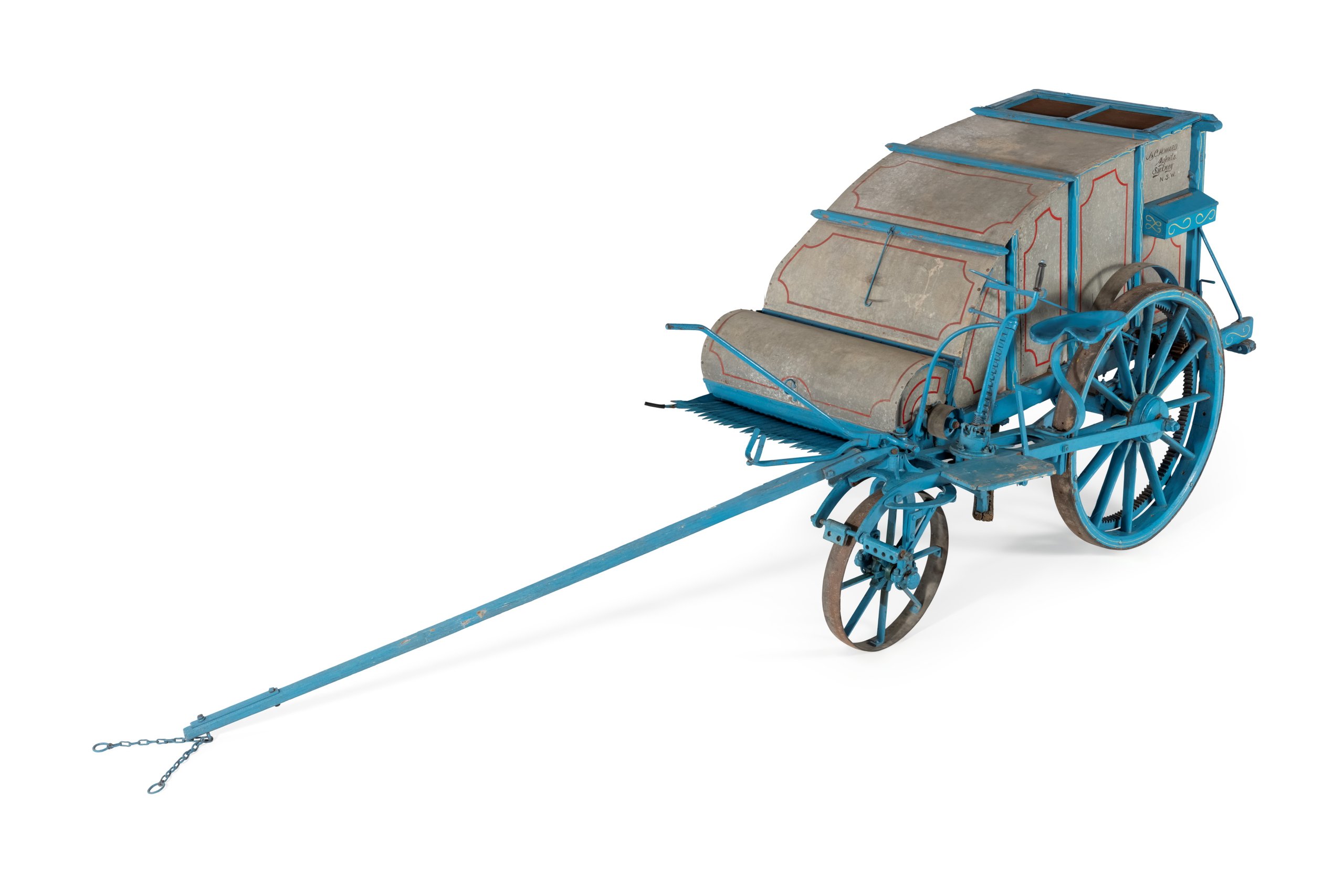

Harvester made by James Martin & Co Ltd

Object No. H10350

The stripper was an Australian invention which revolutionised the harvesting of wheat in the mid. 19th century. It was especially valuable in the hot, dry climate of South Australia where the grain dried on the stalk and the straw was of little value. The stripper not only enabled larger paddocks to be sown with wheat but solved South Australia's chronic labour shortages. Prior to its introduction the crop had to be manually cut laboriously with a sickle or scythe, tied into bundles and placed into stooks in the field to dry before threshing. The stripper was a mechanically simple machine to make in small engineering workshops and inexpensive to purchase. It was so successful in South Australia that by 1864 nearly 90% of the wheat was being harvested with it and 10,000 machines had been sold by 1883. The machine made possible a remarkable expansion of the wheat belt in that State, from 1,000 acres in 1840 to 168,000 acres by 1856. It was the lightness and low cost of the stripper which enabled new farmers to get started on the land and grow wheat well into marginal areas. In other States adoption of the stripper was slower. Western Australia continued using the scythe for harvesting well into the second half of the 19th century while in Queensland the farmers were even more conservative. In 1893 the Queensland Department of Agriculture despaired at introducing either the stripper or reaper-binder as they were thought too costly at 60 pounds each. Instead they urged farmers to use the scythe and cradle. As well as South Australia, the stripper was commonly used in northern Victoria and western New South Wales. It required long hot summers to fully ripen the crops so the heads could be easily "knocked off" as its efficiency depended on the crop being ripe and dry. The machine did not work well in moist areas such as southern Victoria and the New England region of New South Wales where the reaper-binder was preferred. The stripper used less labour than the reaper-binder but the latter could also cut oats and barley as well as wheat and delivered the straw for use as fodder or stock bedding. The Australian farmer habitually burned the straw left standing in the paddock, for which the stripper was ideally suited. The stripper remained in dominant use for harvesting cereal crops in Australia until about 1910 despite the invention of the more complicated and expensive stripper-harvester in 1884. Its popularity continued well into the 20th century until production finally ceased in the 1940s. J. B. Hirst, 'Martin, James (1821 - 1899)', Australian Dictionary of Biography, Volume 5, Melbourne University Press, 1974, pp 219-220. Simpson, Margaret & Phillip, "Old Farm Machinery in Australia : A Fieldguide and Sourcebook", Kangaroo Press, Kenthurst, NSW, 1991, pp.57-61. Margaret Simpson Curator, Science, Technology & Industry September 2009

Loading...

Summary

Object Statement

Horse drawn harvesting machine, full size, stripper, 5 ft cut, A98, metal / timber, made by James Martin & Co Ltd, Phoenix Foundry, Gawler, South Australia, 1899, possibly used in Dubbo area, New South Wales, Australia

Physical Description

The stripper is basically a box on wheels with a comb mounted in front and a rotating beater placed behind the comb. As the stripper was pulled through the crop, generally by a team of three or four horses, the heads of wheat were held by the teen of the comb. Above the comb and covered by a lid is a star-shaped wheel of several branches terminated by a steel bar. The wheel revolved inside a "concave" covered with blunt studs and was driven at considerable speed from one of the main wheels of the machine. This knocked off the heads of the crop and forced them up an inclined plane to the summit of the box where they were fed into the carrying box which holds 20 bushels. The mixture of grain and chaff was then winnowed with a separate winnowing machine.

DIMENSIONS

Height

2010 mm

Width

2200 mm

PRODUCTION

Notes

The basic principle of the stripper was conceived in about 1843 by John Wrathall Bull, a farmer of Balhannah, South Australia. Bull's machine consisted of a long-toothed horizontal projecting comb fixed to the back of a close-bodied cart. It featured four revolving beaters with square edges which would take off the ears of wheat and deposit them into the body of the cart. At the same time John Ridley, an Adelaide miller, was trying to build a reaping machine like the Gallic one described by the Roman historian, Pliny 1773 years earlier. Ridley's experiment was a failure so he used Bull's principle of the comb and beaters with horses pushing the machine from behind. Ridley did not patent his machine so its simple design was taken up by several South Australian implement makers with great success. J. Adamson, from Mount Barker, South Australia, arranged the stripper so that it could be drawn from the front by horses and Joseph Mellor of Adelaide built a light-weight machine which was very popular. By 1850 Ridley's strippers were being exported and by 1855 they were greatly improved. This stripper was made by James Martin & Co. Ltd at the Phoenix Foundry, Gawler, South Australia, in 1899. The company was established by James Martin (1821-1899) who was born in Cornwall and migrated to South Australia in 1847. After working in Adelaide for John Ridley he moved to Gawler in June 1848 and set up in Murray St as a blacksmith and wheelwright making carts and wagons for ore carting and farm use. By 1852 Martin was making strippers with about 250 being made in 1863 which sold for 65 pounds. Martin's company also made a variety of other agricultural implements including drills, chaffcutters, seeders, ploughs, harrows, cultivators and hay rakes. During the 1870s branches were opened at Gladstone and Quorn in South Australia. Frederick May became a partner between 1874 and 1885 which expanded the product range into mining engineering, while railway wagons were added in 1882 and steam locomotives from 1888. The firm reached peak production in 1898 when Martin's works, covering 18 acres (7 ha), employed 700 men. After Martin's death the following year, the firm was taken over by his nephew, John Felix Martin. It became Martin & Co. but went into liquidation in 1907.

HISTORY

Notes

It is believed this stripper operated in New South Wales, as the Sydney agent's name, J. & C. Howard, is painted on the side. The stripper may have worked in the Dubbo area as it was purchased at an auction of the contents of the Merrilea Farm Museum, Dubbo, in 1984.

SOURCE

Credit Line

Purchased 1984

Acquisition Date

16 August 1984

Copyright for the above image is held by the Powerhouse and may be subject to third-party copyright restrictions. Please submit an Image Licensing Enquiry for information regarding reproduction, copyright and fees. Text is released under Attribution-Non Commercial-No Derivative licence.

Image Licensing Enquiry

Object Enquiry