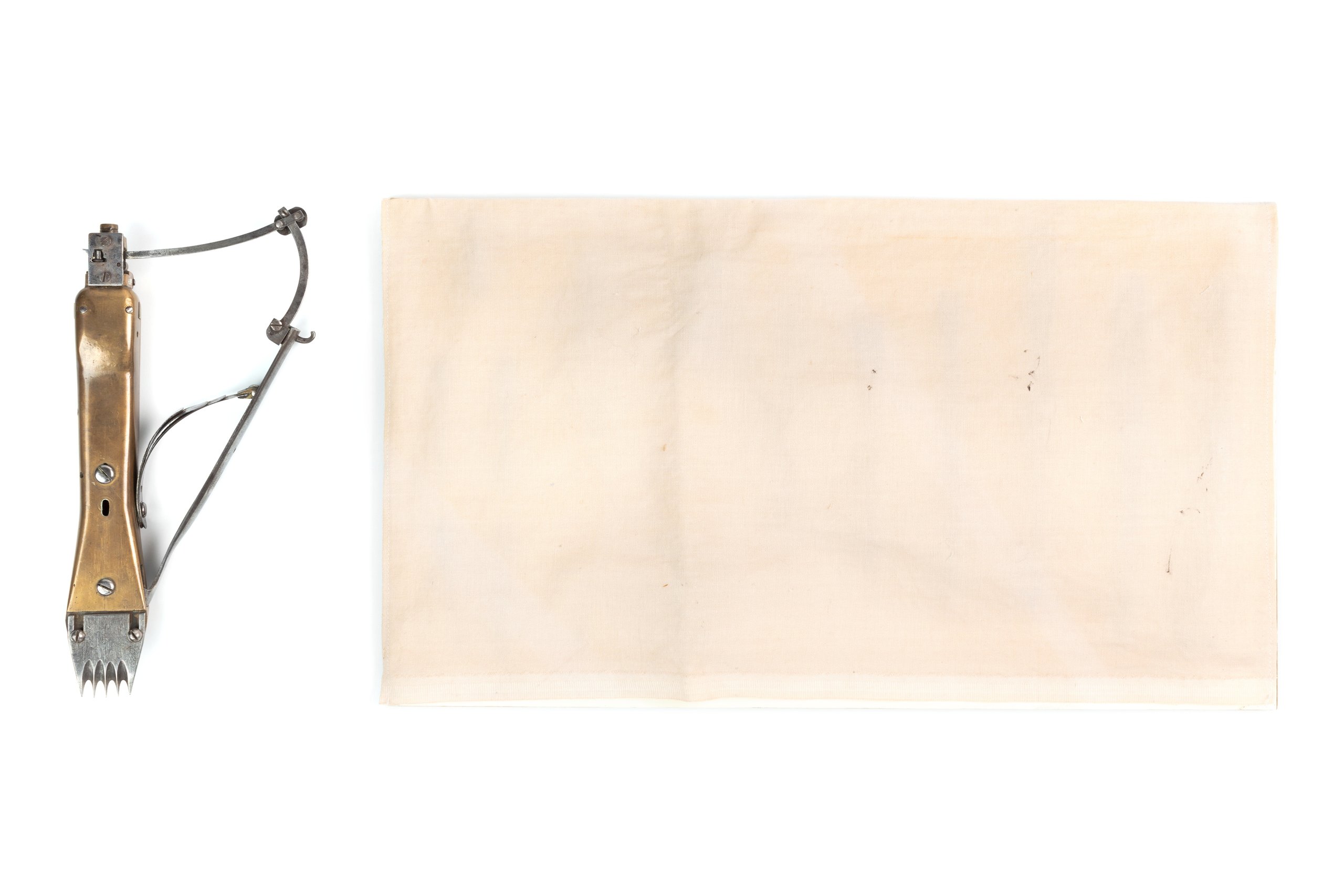

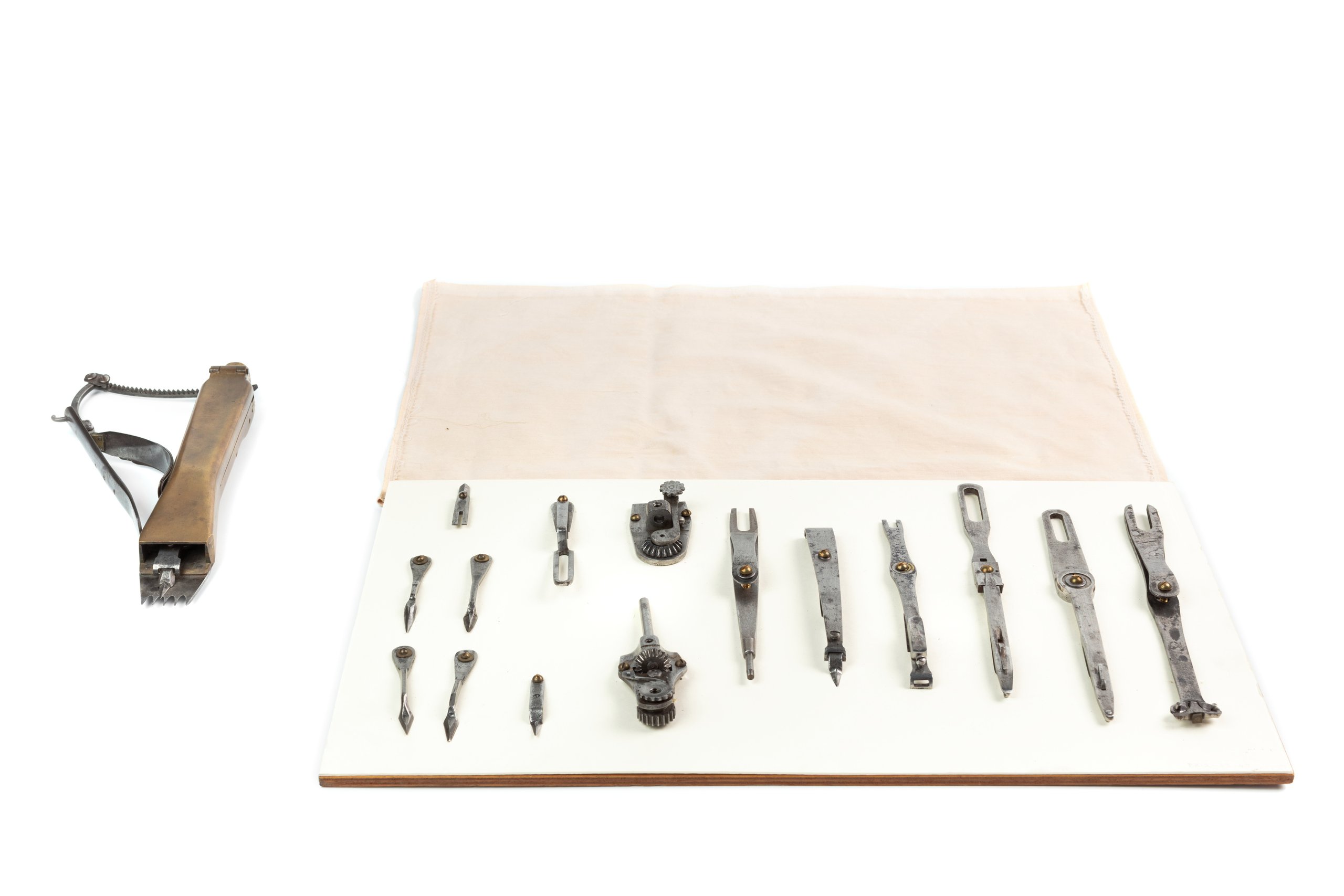

Collection of mechanical sheep shearing equipment

Object No. B812

This is a collection of sheepshearing equipment including mechanical shears, 28 sheepshearing combs mounted on a board and 15 pieces of sheepshearing equipment mounted on a board. Mechanical shears, introduced in 1888, were an Australian innovation that meant that more wool could be shorn from each sheep, and more sheep could be shorn each day. A single engine powered several handsets. Australia's first patent for a shearing machine was granted to James Higham in 1867. The growing sheep population provided ample incentive for inventors to create a machine that would save shearers from the tyranny and agony of hand shears. Steam power and compressed air were both explored, with circular and reciprocating combs and blades. The combs and blades on this board are some of those experimental pieces, and are representative of an endeavour that continued for twenty years. After Fredrick York Wolseley demonstrated his successful machine in 1887, shearing machines were installed in 14 large sheds within a year. Their strongest selling point at the time was that they removed more wool from an animal than did handshears. Although shearers initially regarded them with suspicion and disdain, mechanised shears changed the wool industry. The work was easier and faster for shearers, sheep suffered fewer injuries, the yield of wool was greater from each sheep, and the fleece was cut at a uniform length. The latter affected the value of the wool to textile producers and hence the price of each fleece. Sandra McEwen, Curator, 2007 and Debbie Rudder, Curator, 2014

Loading...

Summary

Object Statement

Sheep shearing equipment, metal / wood, maker unknown, Australia, before 1933

Physical Description

Sheep shearing equipment, maker unknown, Australia, before 1933

DIMENSIONS

Height

9 mm

Width

542 mm

HISTORY

Notes

Capt Arthur Phillip brought 100 sheep from Cape Town when he established the colony of NSW. Unfortunately only 29 survived the journey and these died within a short time of arrival. Nevertheless the sheep population in Australia increased from 105 in 1792 to 100 million by 1892 and the demand for wool increased dramatically. With the greatly increased sheep population and demand for wool came a need for increased productivity in sheep shearing. Consequently there was a surge in development of mechanical means for the shearing of sheep. The shearing of sheep using hand shears has been dramatically depicted in Tom Roberts famous 1890 painting "Shearing the Rams". (This painting is on display at the National Gallery of Victoria). In a similar vein the shearing of sheep using mechanical means has been depicted in "Full Swing on the Board", a painting by Jan Hendrik Scheltema. This painting was probably completed about 1910 when Wolseley's shearing machines were near their peak of interest. (This painting is at the Benalla Regional Art Gallery). James Higham patented the first sheep shearing machine in 1867 (Victorian patent No. 1072); its shearing handpiece comprised a rotary cutter driven by a small turbine using air, steam or water as the source of energy. The rotating cutter design was not successful since the fleece was drawn into the spaces near the sides of the comb and caused tearing and jamming. The second Australian patent (Victorian patent No. 1377, April 1872) was for a complete machine invented by J E A Gwynne. Here the flexibility of the drive was improved by a bevel gear form of universal joint. The comb was circular with a rotary two-bladed cutter and suffered the same fate as that of the James Higham patent. Frederick Wolseley and Robert Savage patented a sheep shearing machine, "Improvements in machine for shearing sheep and clipping horses", in 1877 (Victorian patent No. 2449). This machine also used a revolving cutter and was driven from a rope drive and installed at Euroka station near Walgett, New South Wales. A second patent awarded to Wolseley was for an oscillating cutter, which proved to be more successful in wool severance. In 1884 Wolseley and Park patented improvements to both the handpiece and the flexible driving gear, incorporating a geared universal joint between the drive shaft and the handpiece (Victorian patents 3861 and 3874). During 1886 and 1887 the Wolseley machine was demonstrated in many shearing stations in NSW and Queensland and at Goldsborough Mort Store at Circular Quay in Sydney. As a result of the success of the Wolseley machine, the Wolseley Sheep Shearing Machine Company Ltd was founded by Frederick Yorke Wolseley in Sydney in 1887. A number of patents, issued between 1874 and 1905 to inventors in Australia, England and the United States, were essentially for improvements to the details of shearing handpieces rather than to the mechanism itself. The first operational mechanical handpiece appeared in 1888 at a 40 stand shearing shed at 'Dunlop' station on the Darling River near Louth, NSW where an entire flock of 184,000 sheep were shorn by mechanical means. Another 15 stands used the Wolseley machine at 'Toganmain' station on the Murrumbidgee river near Hay. The future shape of shearing machinery was also determined by Wolseley with the introduction of line shafting and friction wheels to drive individual shearing stations. The use of line shafting allowed a single prime-mover to drive a number of shearing stations, whilst the friction wheels allowed the shearers to operate their shearing handpieces independently. In the late 19th century steam engines provided the power to the line-shaft, but these were replaced by internal combustion engines in the early 20th century. Modern shearing handpieces are likely to be driven by small electric motors using a flexible drive-shaft. The articulated flexible drive-shaft was an important contribution to the development of mechanical shearing since it allowed the shearer to control the handpiece according to the requirements of the occasion. In 1888 James Davidson joined Wolseley and eventually became manager of the sheep shearing machine workshop which was under the control of Dangar, Gedye & Co from 1893. In 1889 William Silver of Tamworth patented, in England, a 'Sheep Shearing Machine' which incorporated a flexible drive shaft to the handpiece. Wolseley's invention proved a timely one for the Australian wool industry, meeting with rapid success. The success of Wolseley's sheep shearer encouraged the company to transfer its operations to England, where Wolseley became managing director of the new Wolseley Engineering Ltd. in Birmingham in 1889. By the end of the century many shearing sheds having 40 to 90 stands were in operation using Wolseley shearing machines. In 1901 Wolseley Engineering Ltd decided to devote itself to its sheep shearing and other agricultural equipment. Wolseley's sales of its sheep shearing machinery continued to build for some time into the new century and, by 1907, the company had sold more than 20,000 in all. Wolseley Engineering Ltd underwent a number of changes and eventually became Wolseley plc in 1986. At about the same time as Wolseley was developing his sheep shearing machinery, another inventor was actively pursuing his ideas for mechanical handpieces which were not dissimilar to those patented by Wolseley. Robert Dangar Dixon (1850 - 1930), an orphan, was brought up by his aunt, Mrs Henry Dangar, and in school holidays enjoyed time at Henry Dangar's station 'Neotsfield' in the Hunter Valley. He worked for some years on various properties and eventually, whilst working near Nundle in the Clarence valley, turned his attention to the invention of a sheep shearing machine. His first step was to build a lathe on a frame of iron-bark with a bullock bow for the spindle. Most components for his experimental shears were made on this lathe, supplemented by hand forging combs and cutters from cross-cut saws blades. Unfortunately his experiments never proved to be successful and in 1905 he realised that others had achieved his dream. In 1909 Dangar, Gedye & Co arranged with R A Lister & Co to manufacture new sheep shearing machines with James Davidson as manager. Davidson continued with patented improvements to handpieces from 1911 to 1936, when he died. During the 20th century several manufacturers produced sheep shearing machines which, in the main, involved improvements to the Wolseley concept. The most significant improvements were the so-called tension pin and the 'chicken claw' fork yoke. This yoke provided further support to maintain close contact between the cutter and comb, and also controlled the oscillatory motion of the cutter blade. The tension pin provided a means for adjusting the contact between the cutter blade and the comb in order to achieve a clean cut of the wool. The initial designs for handpieces used rotary cutters as this seemed to be the most appropriate concept. They were, however, replaced by the oscillatory motion that is now universal. Another attempt to study the applicability of the rotary cutter was conducted in 1978. The basic flaws in the oscillatory cutting action were vibration and noise but also an inability to discriminate between wool and skin and wool build-up at each end of the cutter oscillation, which required larger comb forks. Unfortunately the rotary cutter suffered from its own problems such as un-cut fibres being the cause of seizure and an inability to shear fine Merino wool. Further information: The catalogues of Lister, Buzzacott, Moffat-Virtue and Cooper, issued in the mid 1930s, showed that line shafting systems were distributed by these companies. The Dangar, Gedye General Catalogue no 53, 1935 dealt with Lister Sheep Shearing Machine Co (Lister Bluebeard handpiece). The knife specialist manufacturer, Burgon & Ball Ltd of Sheffield established the Burgon Sheep Shearing Machine Co in Regent St, Sydney to market its version of the Wolseley pattern handpiece. References: "This Century of Ours", Dangar, Gedye & Malloch "Sheep Shearing Experting", LD Ryan, PHM Library number 636.30833 RYA "Robots for Shearing Sheep", J P Trevelyan, PHM Library number 636.3145 TRE (see p133) "Digging Stick to Rotary Hoe", Francis Wheelhouse, Rigby Ltd. Noel Svensson, Powerhouse Volunteer, October 2007

SOURCE

Credit Line

Gift of Mr S A Spencer, 1938

Acquisition Date

17 October 1939

Copyright for the above image is held by the Powerhouse and may be subject to third-party copyright restrictions. Please submit an Image Licensing Enquiry for information regarding reproduction, copyright and fees. Text is released under Attribution-Non Commercial-No Derivative licence.

Image Licensing Enquiry

Object Enquiry