1913 Sheffield Simplex Type 7B tourer

Object No. B2533

This Sheffield Simplex automobile, built in 1913, is a rare surviving example of the luxury touring cars built in England by the Sheffield Simplex Motor Works Ltd of Tinsley, near Sheffield. Only two other cars of this make are known to exist. The Sheffield Simplex evolved from the Brotherhood car made by the London based Brotherhood Engineering Company. That car's designer, Percy Richardson, encouraged the wealthy Earl Fitzwilliam to finance a new company to produce the "best car in the world" to compete with Rolls Royce. The name of the company was carefully chosen, incorporating "Sheffield", which played on the reputation of the world-famous steel-producing city, and "Simplex", which conveyed the simplicity of running the car. The first Sheffield Simplex, which had a 45 horsepower engine, was built in 1909. The 30 horsepower model, of which the museum's car is an example, was first produced in 1913. Each car was painstakingly built from quality materials and components. Assembly took one week, and final testing often took several weeks, with frequent stripping down of the transmission to make sure each car ran as quietly as possible. Each Sheffield Simplex car was built to the client's specifications for body style, accessories and colours. The seats were built exactly to the client's requirements, with the assistance of an adjustable mannequin to ensure they would suit the planned occupants. During the First World War the company made reduction gears for airships, naval shells, magnetic sea mines, chassis for armoured cars, and ABC Wasp and Dragonfly aero engines. Car production resumed after the war, but the bottom had fallen out of the luxury car market and few orders were taken after the 1920 Olympia Motor Show. Between 1921 and 1926 the Sheffield Simplex company made its curious Ner-a-Car motorcycle, of which the museum has an example. Its last car was probably one made in 1925 for Earl Fitzwilliam, who is said to have lost a quarter of a million pounds by investing in the company. Very little is known about the history of the museum's Sheffield Simplex. One owner was almost certainly Sir Samuel Henry Egerton Barraclough (1871-1958), professor of mechanical engineering at the University of Sydney. The Sheffield Simplex formed part of a collection which included gas engines, aero engines and models used as teaching resources in the Engineering School at the University; many significant items from this collection were later donated to the museum. Margaret Simpson

Loading...

Summary

Object Statement

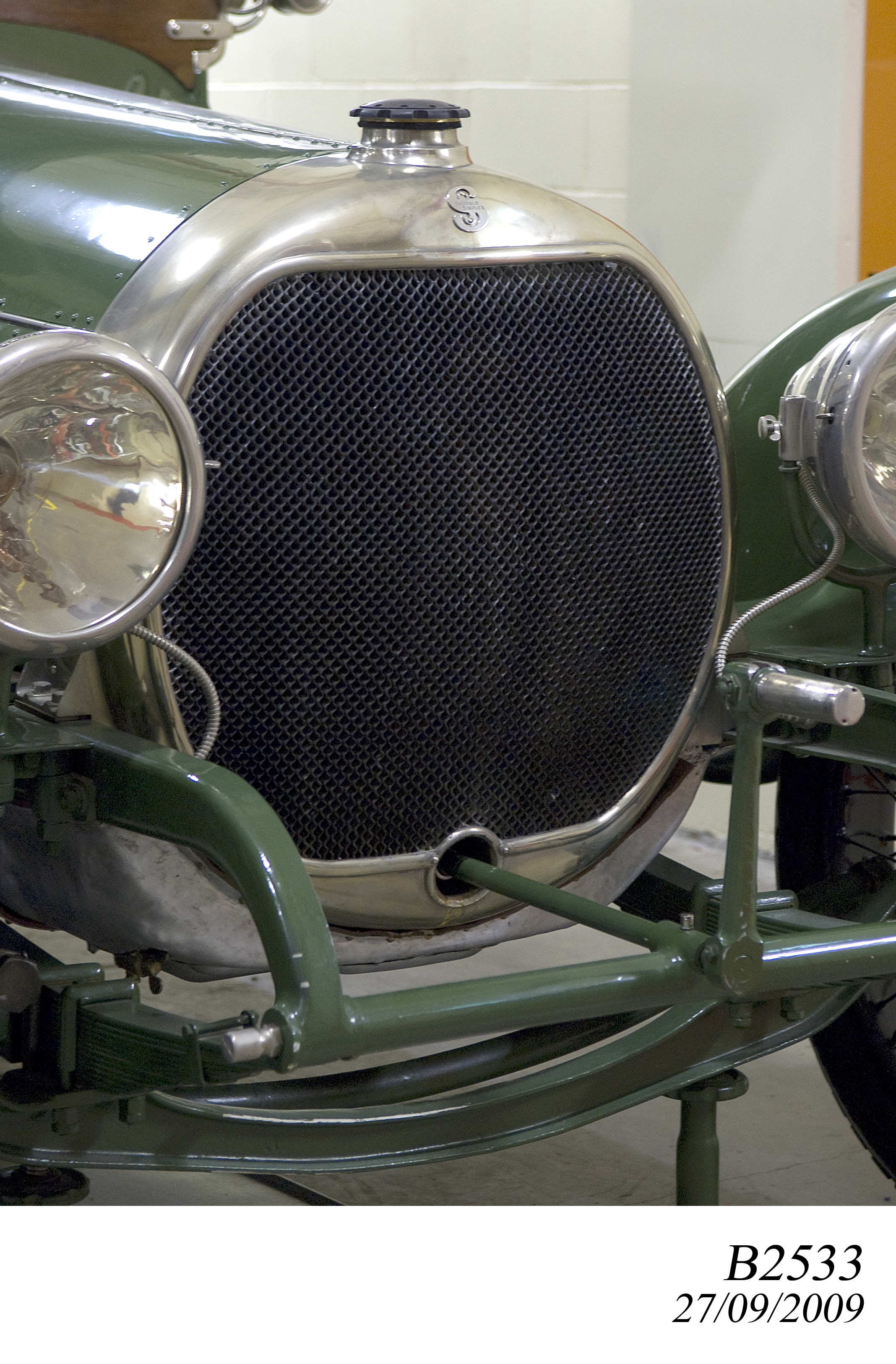

Automobile, full size, Sheffield Simplex, Type 7B, open four seater torpedo touring body and 6 cylinder engine, chassis made by Sheffield Simplex Motor Works Ltd, body made by Van den Plas, England, 1913.

Physical Description

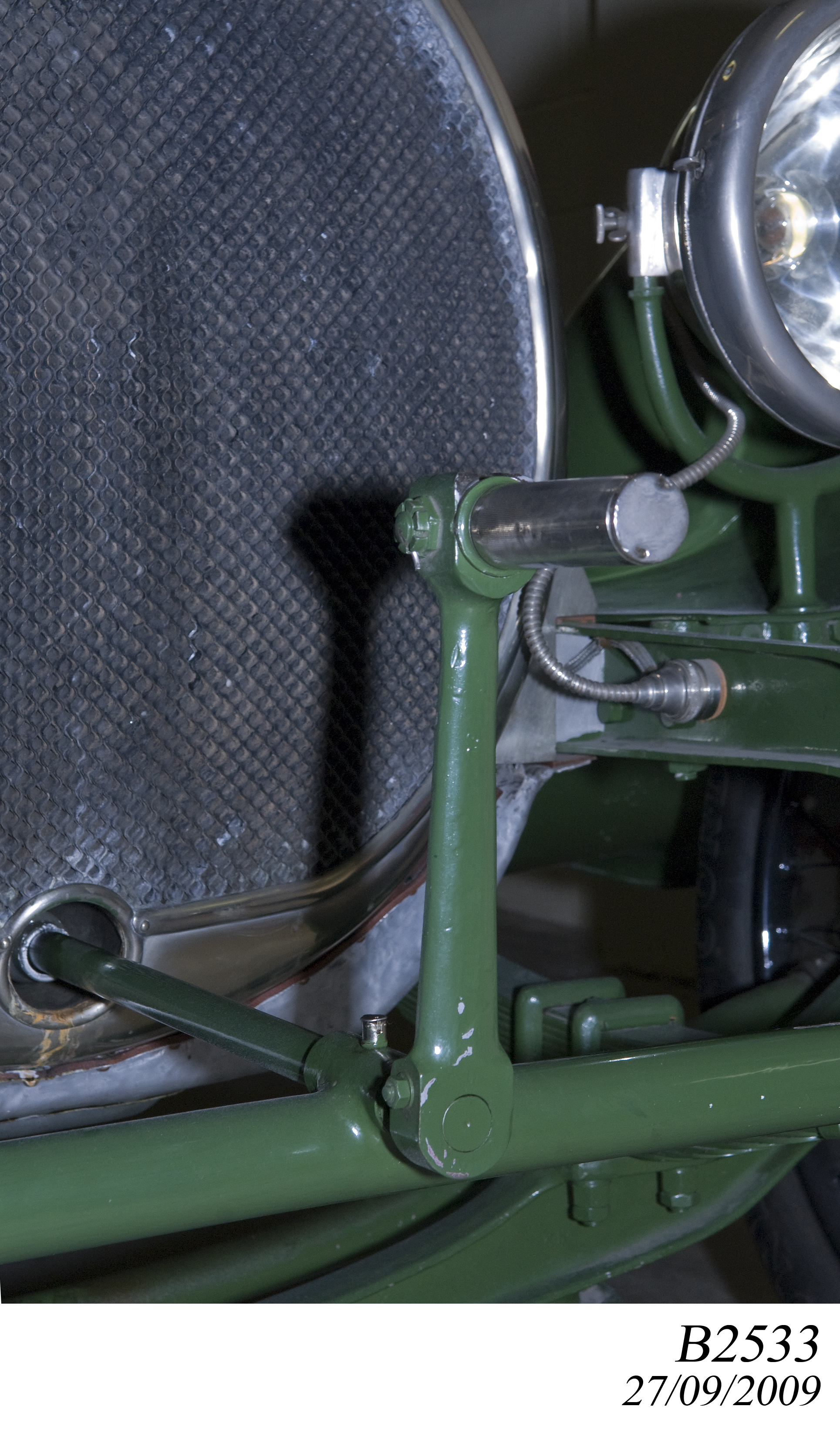

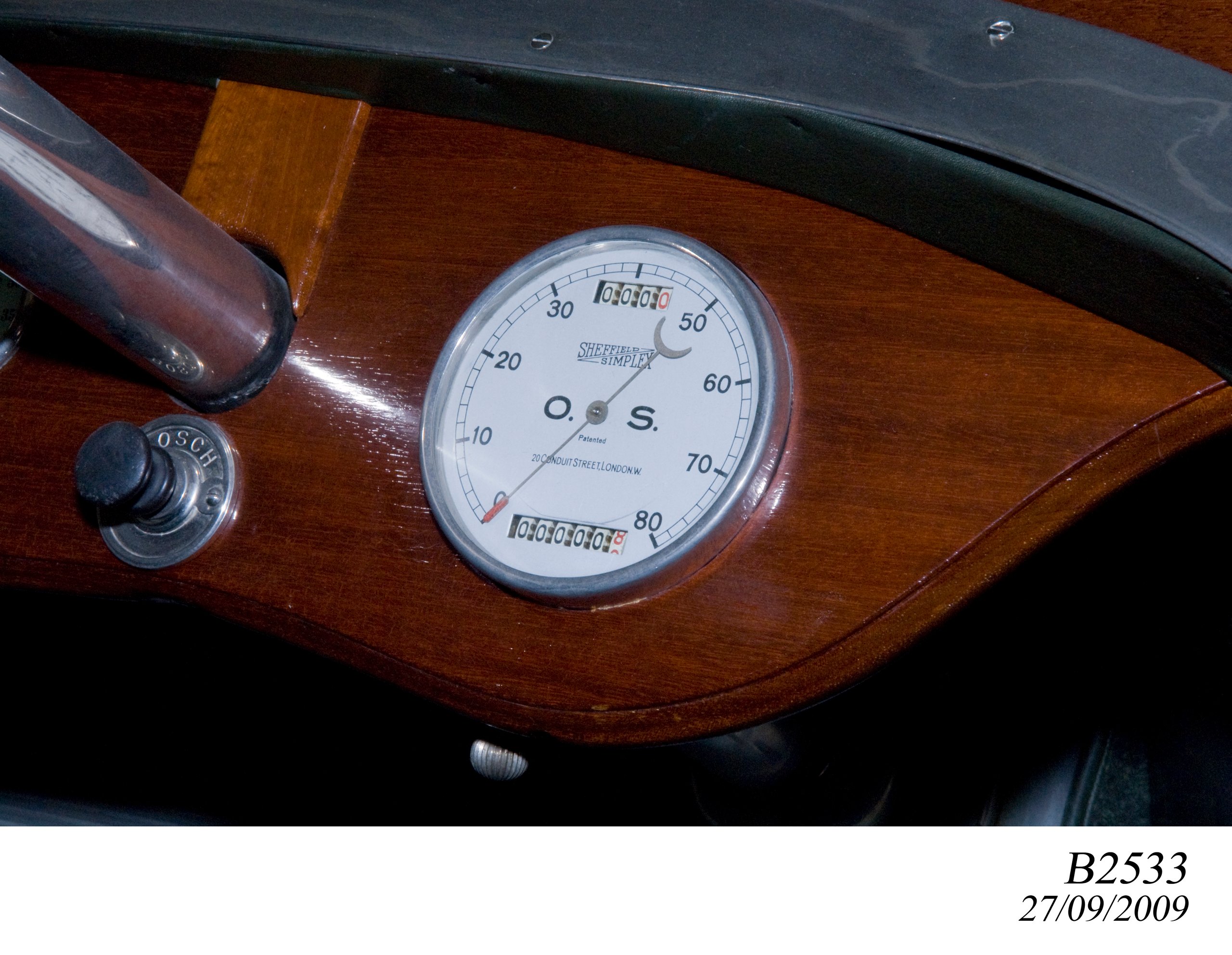

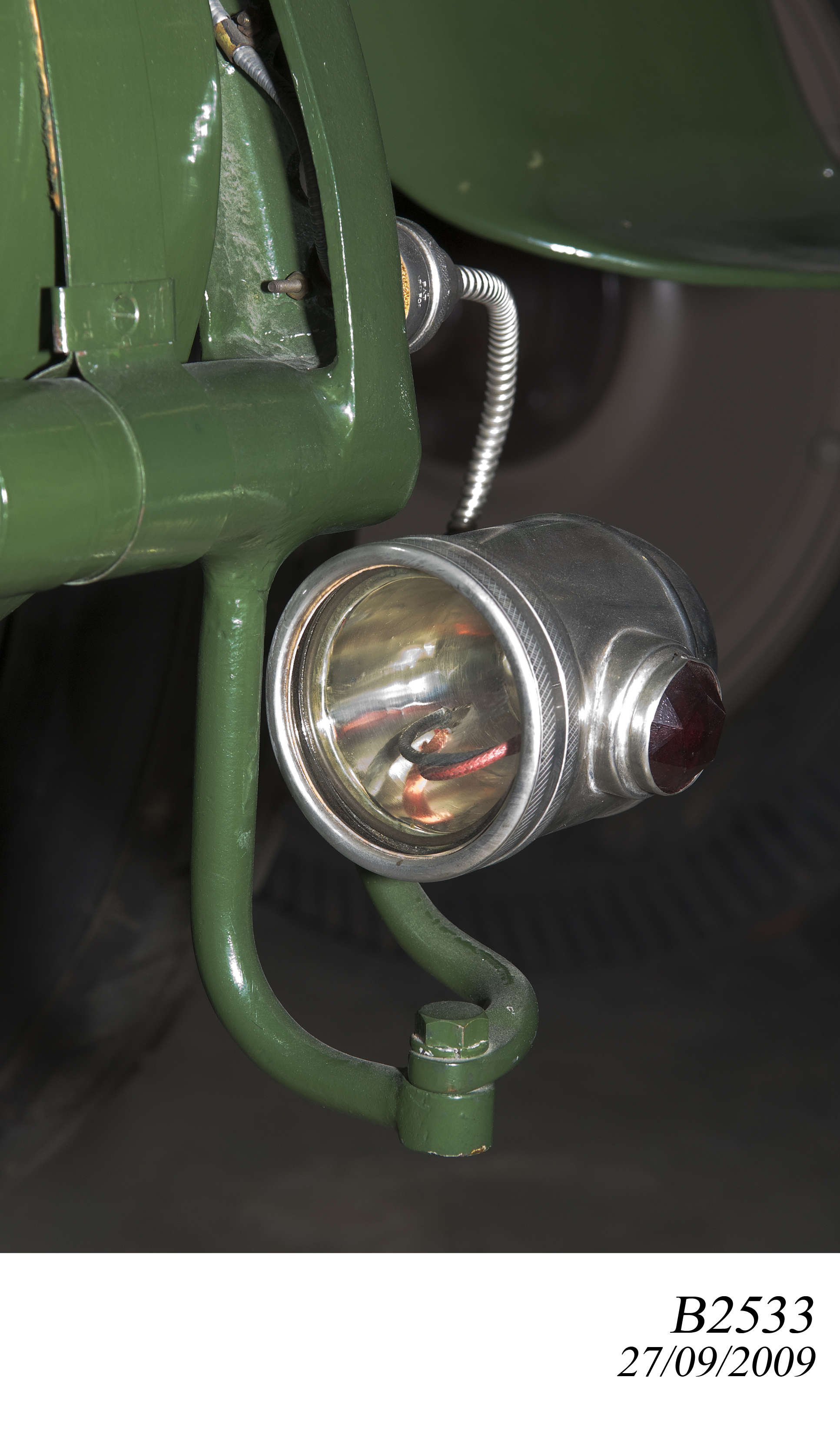

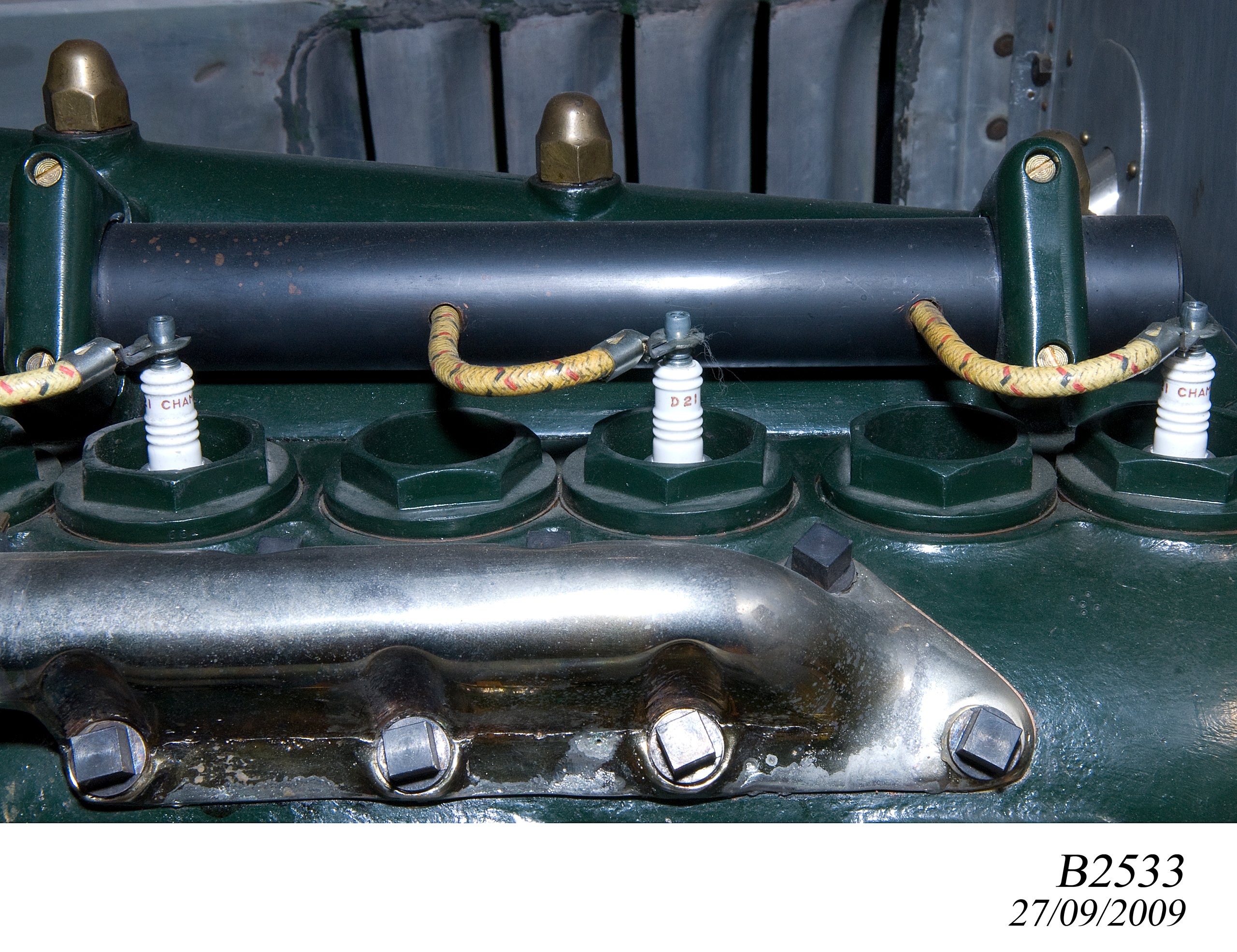

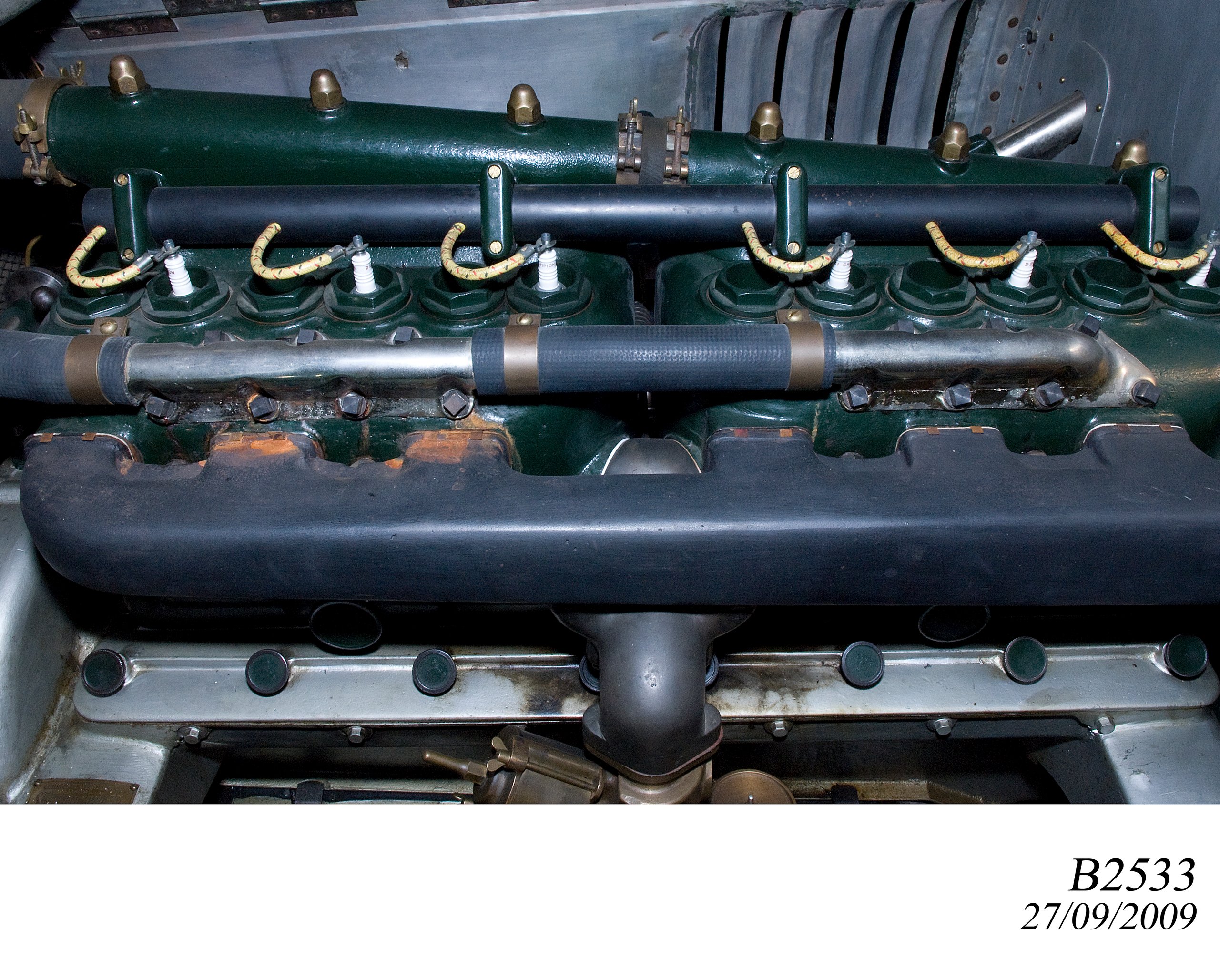

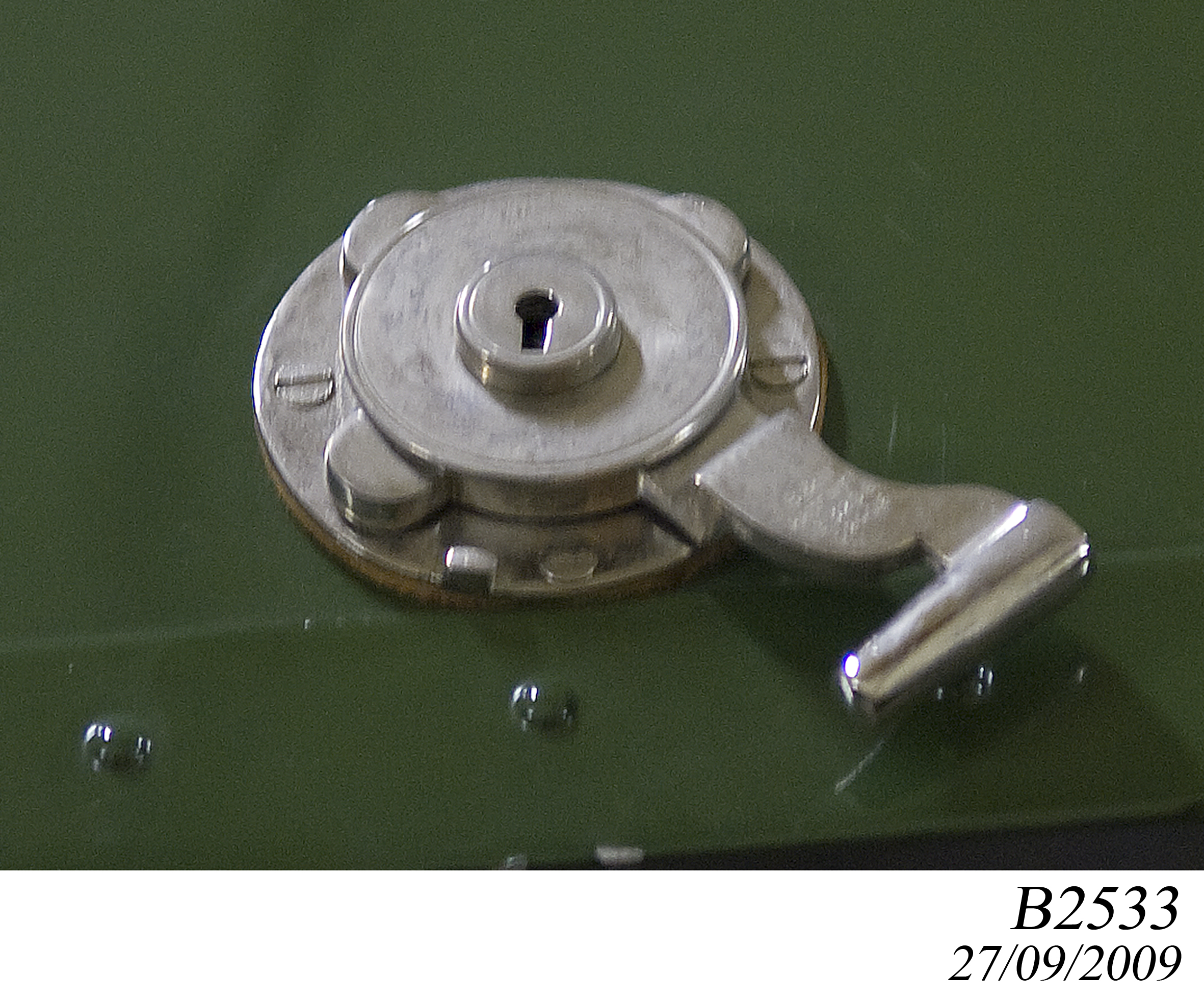

The coachwork is by Van den Plas of London and is an open, four-seater torpedo touring body with four doors and a detachable hood. The body is made of aluminium and the side panels are flush, with the door handles being located on the inside only. The hood is made of khaki-coloured Birkmyre canvas with a bevelled glass oval window at the back. The seats are bench types back and front, upholstered in dark green leather with diamond pattern buttoning. They are covered with khaki Birkmyre canvas seat covers, and the interior door panels also have detachable canvas covers. The aluminium step, or running board, on the passenger side holds the timber battery box. The spare wheel is carried in a well on the step beside the driver's door; it is kept upright with a special bracket and secured with a thin leather strap. The windscreen is split horizontally and can be detached from the car. The engine has six cylinders cast in two groups of three with non-detachable cylinder heads, screw-in valve caps, enclosed side valves and a chain-driven camshaft. The carburettor is a Zenith compensating type with a diaphragm piston. The gearbox has four forward gears and one reverse gear, and the gate change and gear lever are mounted on the driver's right hand side. Lubrication is by a pinion pump driven by an extension of the inclined worm shaft. This circulated oil to the seven main crankshaft bearings. Oil thrown out of the bearings flowed to troughs under the big ends and splashed oil to the rest of the engine. Specifications Builder: Sheffield Simplex Motor Works Ltd, Tinsley, Sheffield, England, Year: 1913 Type: 7B Power: 30 horsepower Identification No. (on fire wall): 1081 Identification No. (on chassis): 1090 Number of cylinders: 6 Bore and stroke: 3.5 inches x 5 inches (89 mm x 127 mm) Capacity: 4741 cc Carburettor: Zenith Cooling: Thermo-syphon Lubrication: forced Clutch: disc Weight: approx. 2 tonnes

DIMENSIONS

Height

1900 mm

Width

1900 mm

PRODUCTION

Notes

The Sheffield Simplex evolved from the Brotherhood car made by the London based Brotherhood Engineering Company. This company had its beginnings in steam engineering in the nineteenth century. The firm began making motorcars towards the end of 1904 under the leadership of designer Percy Richardson, the ex-Daimler company London manager, and under the name of Brotherhood-Crocker. The company's first car, a conventional 20 horsepower 4 cylinder chain-driven machine similar to Mercedes, was constructed at a purpose-built factory at West Norwood near London. In 1906 it was decided to move the factory to Tinsley, on the road between Rotherham and Sheffield, on land provided by one of the Board of Directors, Earl Fitzwilliam. By the time the new factory was built the motor industry had gone into decline, causing Brotherhood to withdraw from the industry. Percy Richardson fired the imagination of the wealthy Earl Fitzwilliam to finance a separate company and produce the "best car in the world", comparable with Rolls Royce. Percy Richardson ran the company as both designer and managing director. He subsequently took on C.R. Garrand, previously of the Clement-Talbot Company, as his works manager. The factory at Tinsley had five main bays which housed blacksmiths, engine testing, car testing, running shed and pattern shop. The front of the building was occupied by administrative offices, the boardroom and the drawing offices. The factory was fully equipped with up-to-date machinery from all over Europe. Until a completely new design could be brought out, the newly formed Sheffield Simplex company produced, in 1908, what were really 20 horsepower Brotherhood cars. Later it produced a six-cylinder car known as the 20/30 and a smaller car, the 14/20, both of which were copies of contemporary Renaults. The first true Sheffield Simplex was built in 1909 and was a 45 horsepower model. It had a seven litre engine and six cylinders grouped into two sets of three in the same way as the Rolls Royce cars of the time. The side valves were all on the near side, timing was by enclosed spur gears, and ignition was by magneto. A two-pedal control system, pioneered by Richardson on the Brotherhood, was again used, as was an unusual sliding accelerator pedal and combined clutch and brake pedal. The model was promoted as "The Gearless Car", and operation in top gear was normal due to the large amount of torque developed by the engine. The "gearless car" was popular with its clientele, but critics pointed out that the gearing limited the speed to around 60 miles per hour (96.6 km/h). To enable a higher maximum speed to be obtained without sacrificing the machine's overall refinement, Richardson was forced in 1911 to abandon this feature and adopt a three-speed gearbox mounted on the rear axle. The 30 horsepower model produced in 1913, of which the Museum's vehicle is an example, has been described as possibly the company's greatest car. Each automobile was painstakingly built with quality materials and components. Assembly took one week, while final testing would often take several weeks with frequent strip downs of the transmission to ensure quietness of operation in each vehicle. The chassis frames were made in the factory, but the cast iron engine blocks were made by Henry Wallwork at Newcastle, brass bushing and brass and alloy castings were from William Brothers of Green Lane, Sheffield, and the distinctive radiator was made by Orme Evans at the Phoenix Works at Wolverhampton. However, the Sheffield Simplex company cut its own gears, and camshafts and made its own bonnets and spark plugs. A number of car chassis were dispatched by rail, as the factory had its own railway siding. Road testing of vehicles involved a circuit of some of the local notorious hills. On the roadside at a place called Tatley Rise, a sign stated that the Sheffield Simplex could climb this incline in top gear. The strongest indication that Sheffield Simplex had its sights firmly on the Rolls Royce market was the fact that by 1913 it had acquired London showrooms at 20 Conduit Street, five doors down from Rolls Royce. In 1979, 20 Conduit Street was the office of the German Tourist Board, but the Rolls Royce showroom was still nearby. Each car body was built to the client's specifications for style, accessories and colours. The seats were custom built exactly to the client's requirements and placed correctly in position by means of an adjustable mannequin. Two of the coachbuilders used by Sheffield Simplex were Van den Plas of London and Cunand's of Putney (in London). The coachwork on the Museum's Sheffield Simplex is by Van den Plas. This company was founded in Brussels in about 1870, and the British arm of the firm was established in 1912. In 1946 Van den Plas was purchased by Austin, later to become part of British Leyland. Earl Fitzwilliam was the chairman and sole proprietor of the company, and it was said that he personally vetted all "applicants" who wished to purchase his cars. It is doubtful whether this in fact occurred but rather was a story put around to imply greater exclusiveness for the Sheffield Simplex over its rivals. Just before the First World War, Sheffield Simplex conducted experiments for the War Office involving the 30 horsepower models towing field guns. When war broke out the factory was taken over by the British Air Ministry, and reduction gears for R31 and R31 airships were made there. It appears that the design was influenced by a German airship engine from Zeppelin l31, which was brought down near London. An old employee of the company recalled the airship engine arriving at the works and the havoc it caused upon operation. A special rig was built to hold the vast engine and, on firing-up, the rush of air from the huge propeller blew the door and windows out of the Test Building. The engine was then turned around, only to rip off part of the roof. During the war naval shells, the factory produced 18 pound (8.2 kg) armour piercing shells, magnetic sea mines and ABC Wasp and Dragonfly aero engines. After the war a large number of aero engines were left over at the factory, and nobody in Government circles appeared to want them. Consequently, a large pit was dug in the factory yard and the engines were dumped into it. During the war 12 armoured vehicles were produced in the factory and sent to Russia in July 1916. These were hurriedly assembled from spare parts and made with rough steel plate bodies. Two of them were fitted with barbed wire cutters worked by levers from within. Previously, the armoured cars had been shown to the British War Department, which apparently showed no interest. Car production resumed after the war with the 30 horsepower model, but the bottom had fallen out of the luxury car market and few orders were taken after the 1920 Olympia Motor Show. The factory moved to a new building in Canbury Road, Kingston-on-Thames in Surrey, an old Sopwith Aviation Co. building. It was here that the curious Ner-a-Car motorcycle was produced from 1921 to 1926. The Museum has an example of a Ner-a-Car motorcycle (B1577). The final years of production are something of a mystery, and probably the last model built was in 1925 for Earl Fitzwilliam. The Tinsley factory was involved in the manufacture of 30 hundredweight (1.5 tonne) petrol lorries for Commers of Luton. However, a slump after 1919 saw both firms in serious difficulties. Earl Fitzwilliam pulled out the Sheffield Simplex company, but not before reputedly losing a quarter of a million pounds. The Tinsley factory was taken over by a local businessman named Kuernerick for the manufacture of razor blades. The factory still survives today largely as built, and in 1979 bore the name Darwins Magnets International in place of the Sheffield Simplex Motor Works Ltd. The occupants retained the address as the Fitzwilliam Works as a reminder of an illustrious past.

HISTORY

Notes

Very little is known about the history of the museum's Sheffield Simplex. An early owner is said to have been the Australian sportsman and showman, Reginald Leslie (Snowy) Baker (1884-1953), but this has not been verified. A later owner was almost certainly Sir Samuel Henry Egerton Barraclough (1871-1958). Barraclough was a mechanical engineer who taught applied physics at Sydney Technical College and in 1915 was appointed professor of mechanical engineering at the University of Sydney. In October 1899 Barraclough was commissioned in the Corps of Australian Engineers, and he transferred to the Australian Intelligence Corps in 1908. During the war he served with Intelligence and helped the British war effort by taking some 5,000 Australian skilled workers to England to make munitions. The Sheffield Simplex formed part of a collection which included gas engines, aero engines, and models illustrating mining and civil engineering principles, which were used as teaching resources in the Engineering School at the University. In 1943 the then Professor of Mechanical Engineering, George McDonald, organised for some of the collection, including the Sheffield Simplex, to be lent to the Museum. The car was presented to the museum by the University of Sydney in 1983 and subsequently restored to running condition. The car was part of the initial display in the Transport exhibition when the Powerhouse Museum opened in 1988. It had been planned to enter it in the International Australian Bicentennial Veteran Car Rally in that year, but the museum's 1912 Rover was entered instead.

SOURCE

Credit Line

Presented by the University of Sydney, 1983

Acquisition Date

16 August 1983

Copyright for the above image is held by the Powerhouse and may be subject to third-party copyright restrictions. Please submit an Image Licensing Enquiry for information regarding reproduction, copyright and fees. Text is released under Attribution-Non Commercial-No Derivative licence.

Image Licensing Enquiry

Object Enquiry