Marshall 'Britannia' portable steam engine

Object No. B2386

The introduction of portable engines opened a wider market to the use of steam power. Steam engines had previously been stationary and often dedicated to a single task; they required investment in a separate boiler to supply steam; and they had to be dismantled before being relocated. A land-owner could purchase a portable engine and so obtain a power plant, with self-contained boiler, that could be moved about the property to power different tasks according to the season; or a contractor could purchase an engine and hire it out for use on different properties. Richard Trevithick introduced the practice of employing high-pressure steam. Around 1812 he designed the first portable engines, but they did not achieve commercial success. It was not until the 1840s that the portable engine began to achieve acceptance, with several English firms making variations on the same basic design. Companies in other countries, including Australia, later began manufacturing similar engines. Many thousands of portable steam engines were made between the 1840s and 1920s. Most were used in agriculture, and some were used to drive equipment in factories. Marshall, Sons & Co Ltd and several other companies made engines with 'colonial' boilers for overseas sale; this particular engine is representative of the type, being also fitted with a log-burning grate. The engine was imported in 1914 to power sheep-shearing machinery at Curraburrama, a property located on the western slopes of NSW. Thus the engine is representative of practice in the wool industry, which was then the State's major industry, as most sheep were shorn at shearing stands consisting of several shearing sets powered by a single engine. However, steam power in rural areas was in decline, with oil and gas engines already outnumbering steam engines. The engine met a typical fate, being replaced by a more efficient and convenient diesel engine around 1945. The next phases of the engine's lifetime were also typical: left outdoors, it was gradually stripped of parts and allowed to decay; and then it was rescued and restored. The restorer researched and used appropriate materials, techniques, and finishes, including application of a transfer obtained from the company, which still existed as the tractor manufacturer Track Marshall Ltd. The transfer represents Marshall's pride in its British origins, through the figure of Britannia triumphant in technology, and in its workmanship, as proven by the medals it had won at various exhibitions. Debbie Rudder, Curator, 2007

Loading...

Summary

Object Statement

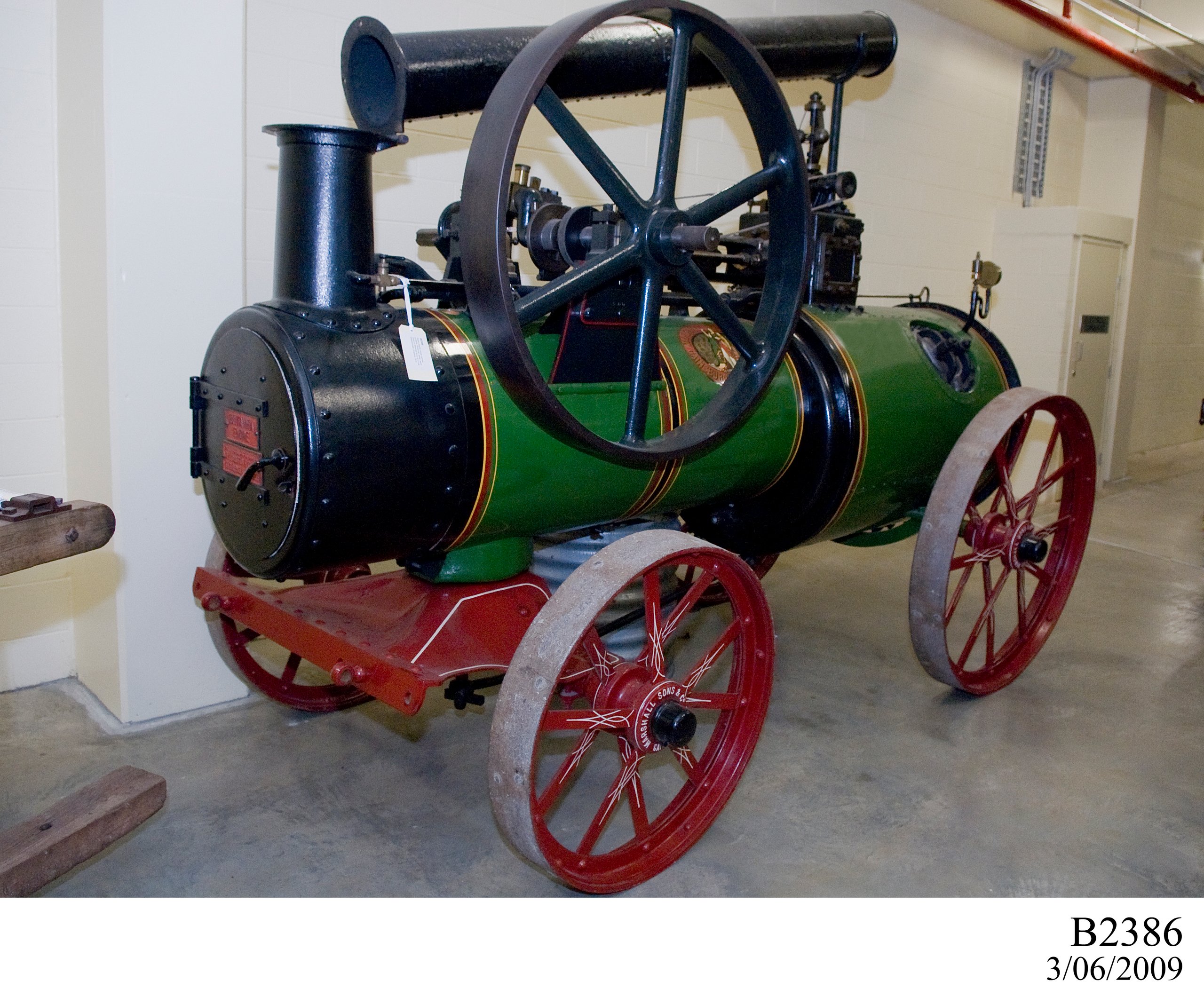

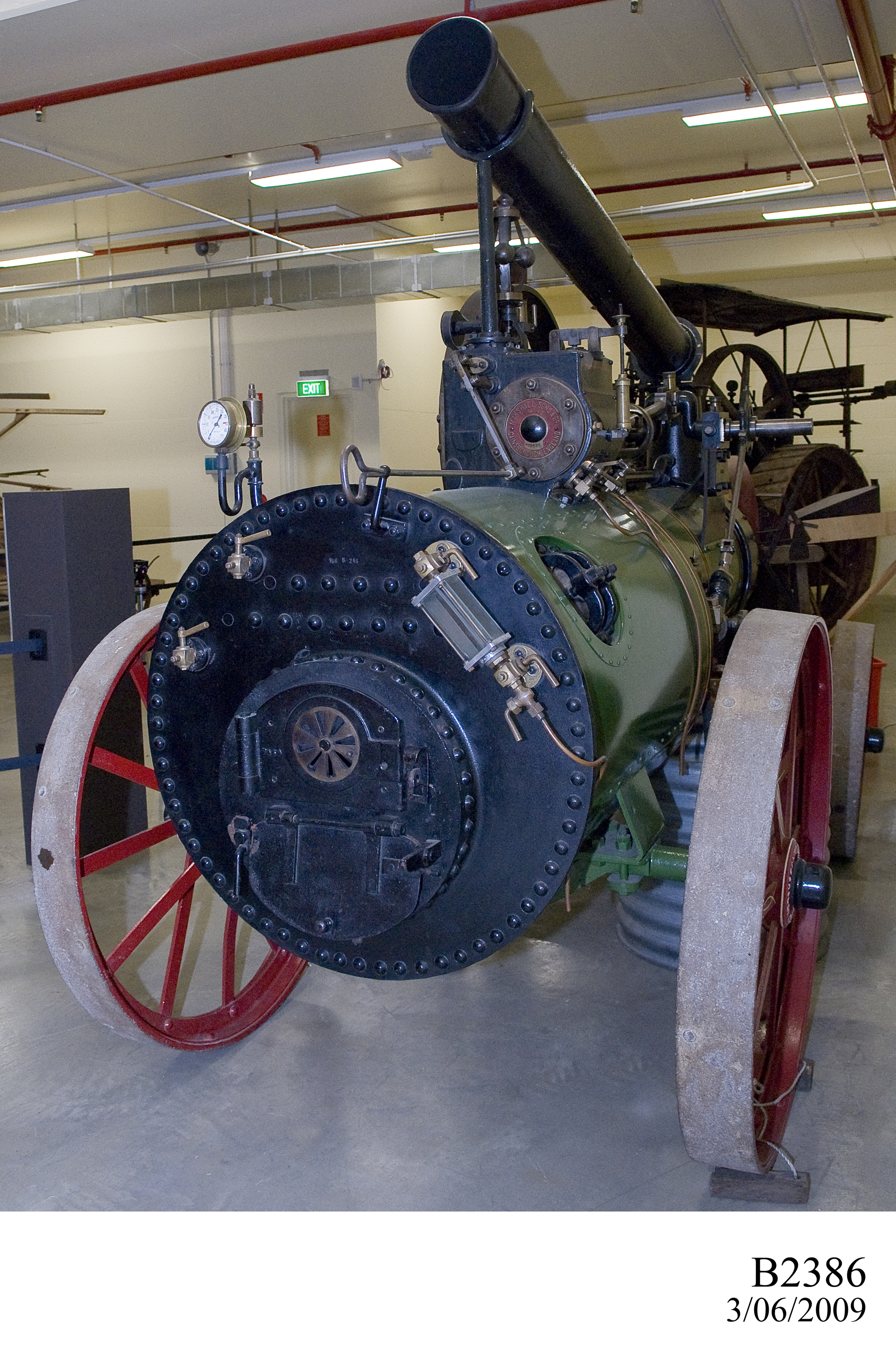

Portable steam engine, single cylinder, 'Britannia', metal / paint, made by Marshall Sons & Co Ltd, Gainsborough, England, 1914

Physical Description

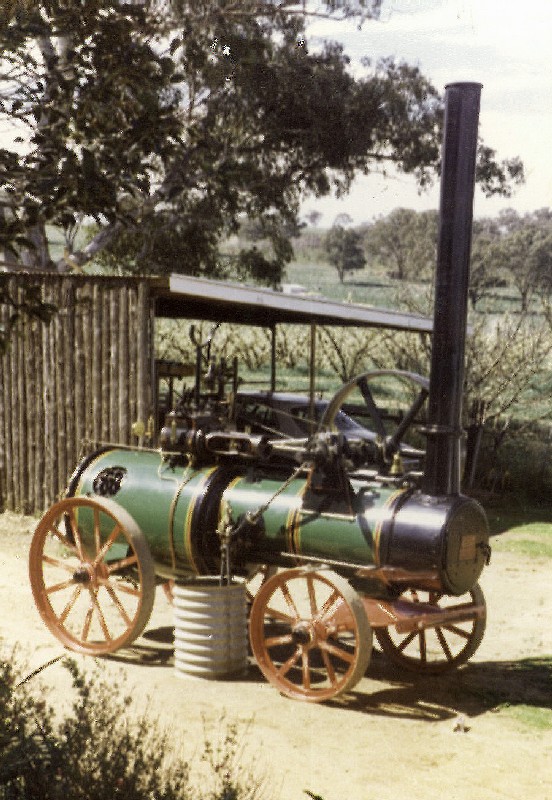

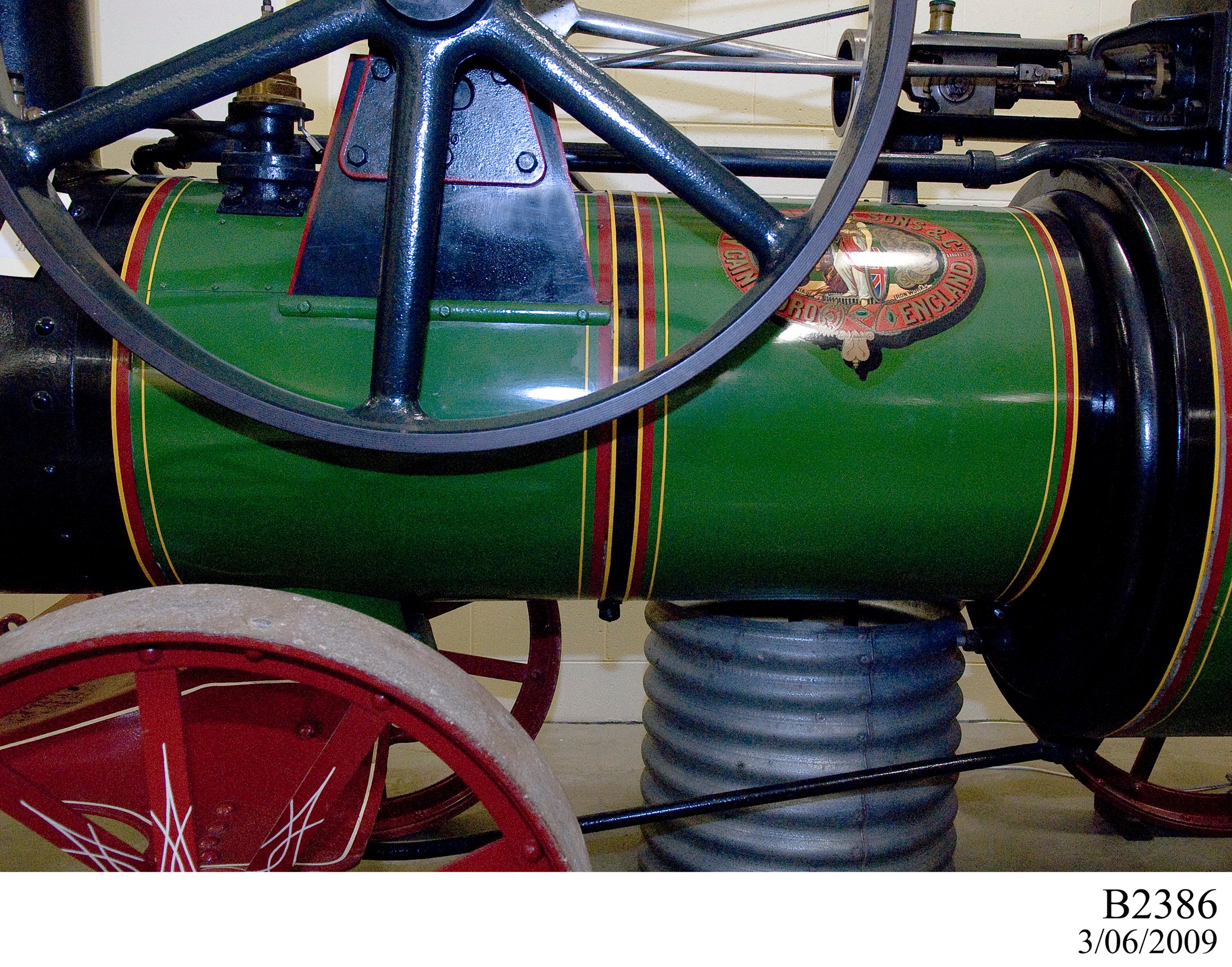

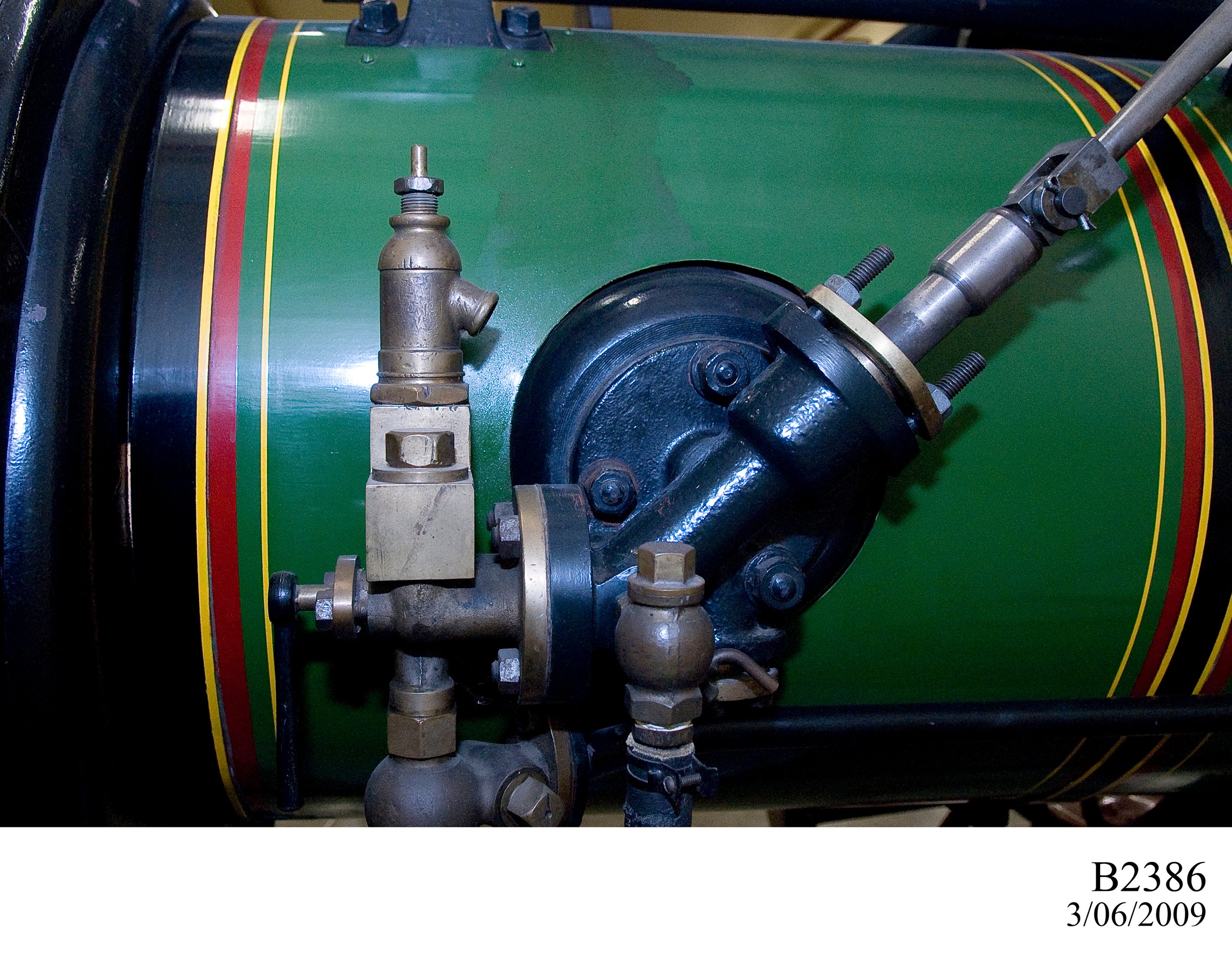

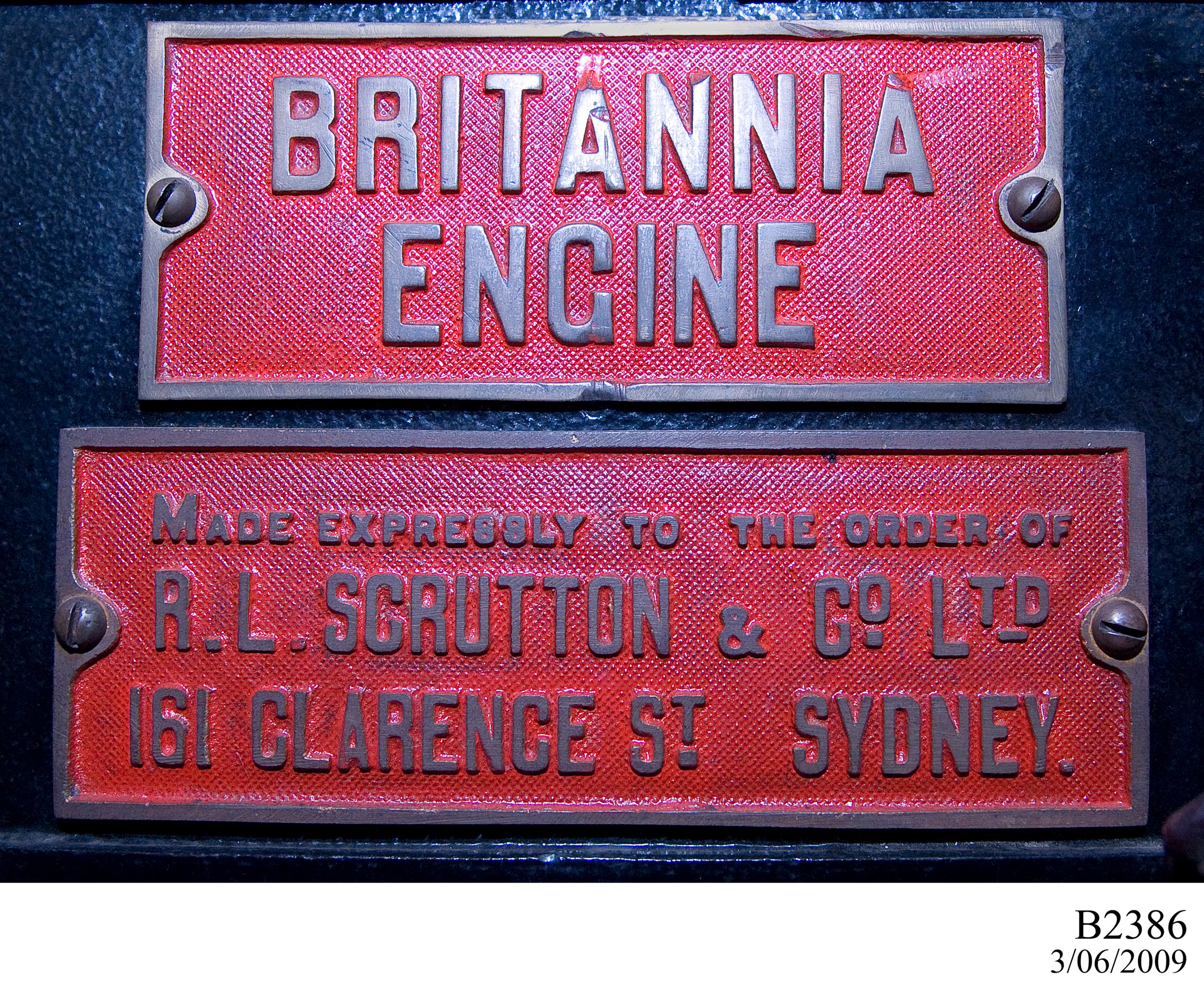

The engine's horizontal cylinder, containing the piston, sits on top of a much larger cylindrical body which is mounted on four road wheels. The piston is connected to an elevated flywheel which serves also as the drive wheel; a belt can be wound around its rim and connected to the equipment it is required to drive. The body is made up of: a cylindrical firebox with log-burning grate, where fuel is burnt; in front of that a fire-tube boiler where water is converted to steam; and in front of that a smoke-box surmounted by a tall stack that carries smoke away, creating a draught of air through the firebox that ensures efficient combustion. Three doors provide access: on the back of the firebox, for introducing fuel; on the side of the firebox, for emptying the ash pan; and on the front of the smoke-box, for cleaning and maintenance. A drawbar mounted between the front wheels allows the engine to be hauled from place to place, and the stack can be folded back at its base to prepare the engine for transit or storage. The engine is painted in green, black and red, with yellow and red hoops around the green boiler and firebox, and white detail on the red wheels. A manufacturer's transfer is affixed to the boiler. It depicts Britannia as a warrior with trident, shield and seated lion; she is standing on a toothed wheel and is surrounded by exhibition medals. The engine, number 65311, has 150 mm (6 inch) bore and 250 mm (10 inch) stroke. It is fitted with a slide valve, a mechanical oiler and a Pickering governor. It operated at 830 kPa (120 psi) and had nominal output of 3 kW (4 horsepower). The boiler has two safety valves and was supplied with water by a feed pump powered via an eccentric on the crankshaft. Inside their riveted sheet-metal exterior, the boiler and firebox are lagged with closely laid long timber strips nailed onto widely spaced timber hoops.

DIMENSIONS

Height

4240 mm

Width

1900 mm

PRODUCTION

Notes

The engine was made at Marshall's Britannia Iron Works, Gainsborough, England in 1914. The build date is recorded as 18th April. William Marshall set up in business as a millwright and engineer at Gainsborough in 1848. By 1849 he was making, and winning an award for, portable threshing machines, which separated grain from chaff and straw in a single operation. William's sons soon joined him in the business, James in 1849 and Henry in 1853. They moved to larger premises in 1855 and established the Britannia Iron Works, which was to grow into a major enterprise making a wide range of engines, boilers, tractors and other machines. In 1857 Marshalls began making portable engines capable of powering threshing machines and other farm machinery. William died in 1861, and the firm was incorporated as Marshall, Sons & Co Ltd in 1862. Its peak year for portable engine production was 1913, when it sold 1300 of them. Many were sold overseas, and it was for these markets that the 'colonial' boiler was designed. Unlike engines with the more usual square-cross-section firebox, the colonial type has high clearance to enable it to negotiate rough tracks; if fitted with a longer grate as this one is, it can be fed with logs rather than short billets of wood. Marshall Britannia portables ranged in output from 3 to 14 horsepower.

HISTORY

Notes

The engine was imported in 1914 by R L Scrutton of 161 Clarence Street, Sydney, agent for Marshall and other British machinery manufacturers. It spent its whole working life at the Bolger family's Curraburrama sheep station at Quandialla, near Grenfell in NSW. It was used to power sheep shearing machinery until about 1945, when it was replaced by a diesel engine; the decision to retire the engine was made because its boiler required repairs and there was a shortage of boiler tubes. The engine was left outdoors. Most parts rusted and some were stripped off it. In 1977 Graham Clegg purchased the derelict engine and took it to Young, where he restored it as closely as possible to original condition and appearance. The Museum purchased it from him in 1981 and the same year lent it to a NSW government department for display at Sydney's Royal Easter Show.

SOURCE

Credit Line

Purchased 1980

Acquisition Date

23 December 1980

Copyright for the above image is held by the Powerhouse and may be subject to third-party copyright restrictions. Please submit an Image Licensing Enquiry for information regarding reproduction, copyright and fees. Text is released under Attribution-Non Commercial-No Derivative licence.

Image Licensing Enquiry

Object Enquiry