Aveling & Porter steam tip wagon

Object No. B1509

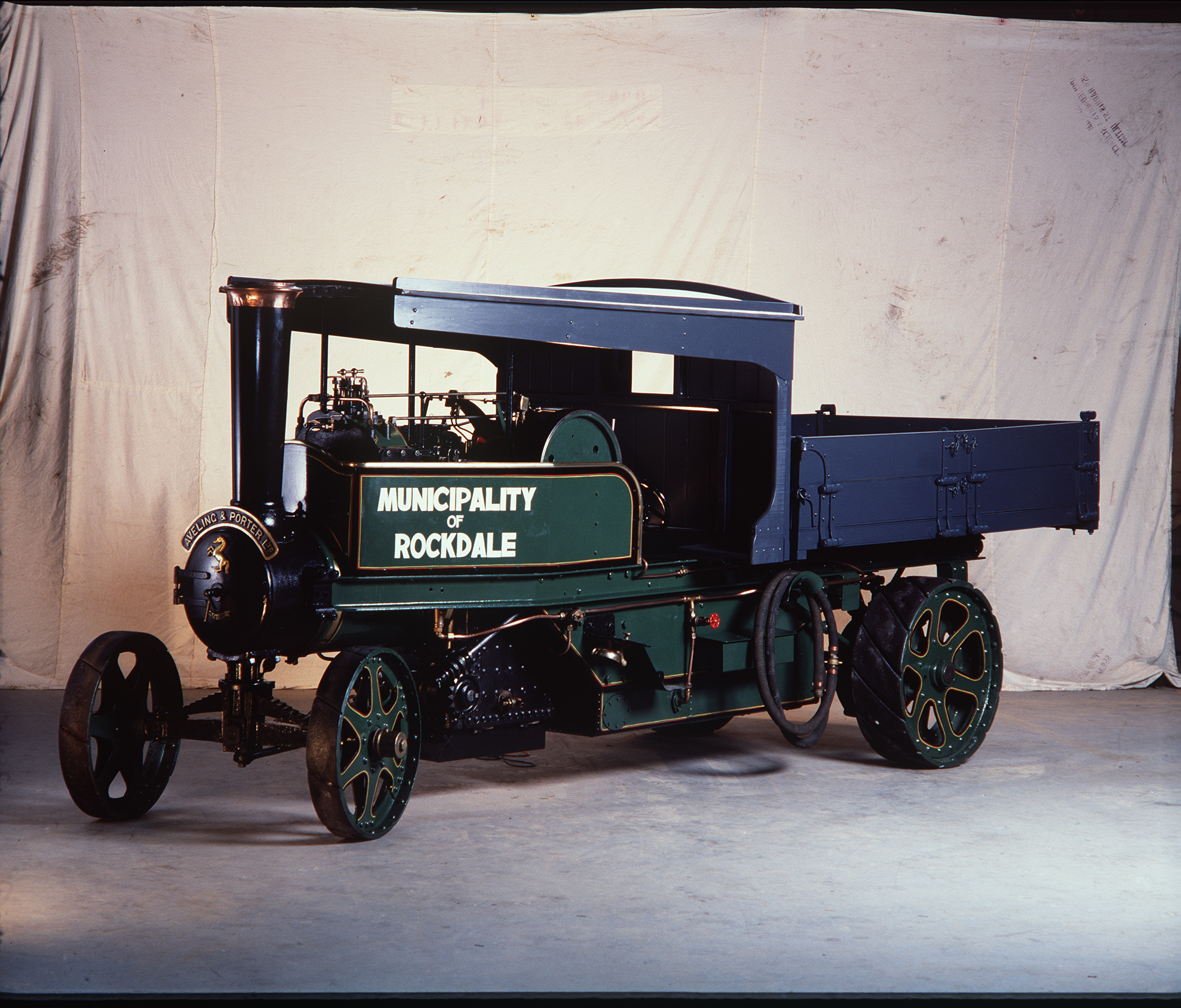

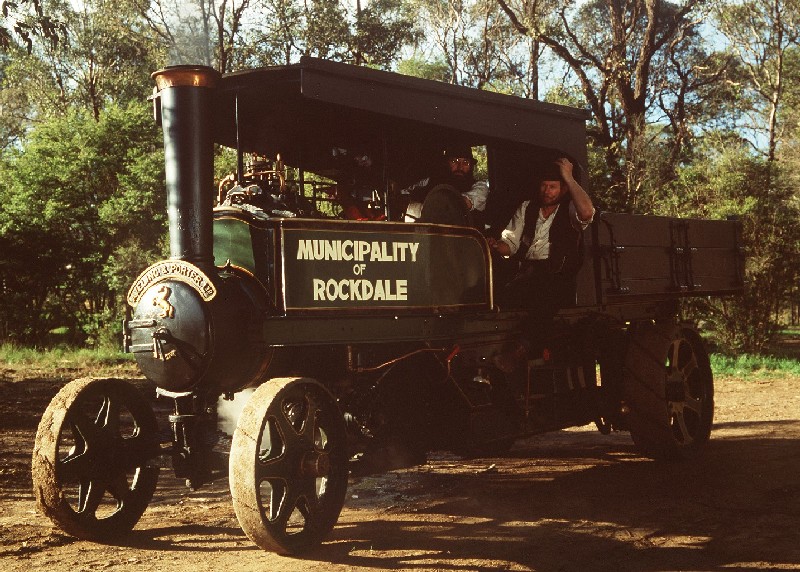

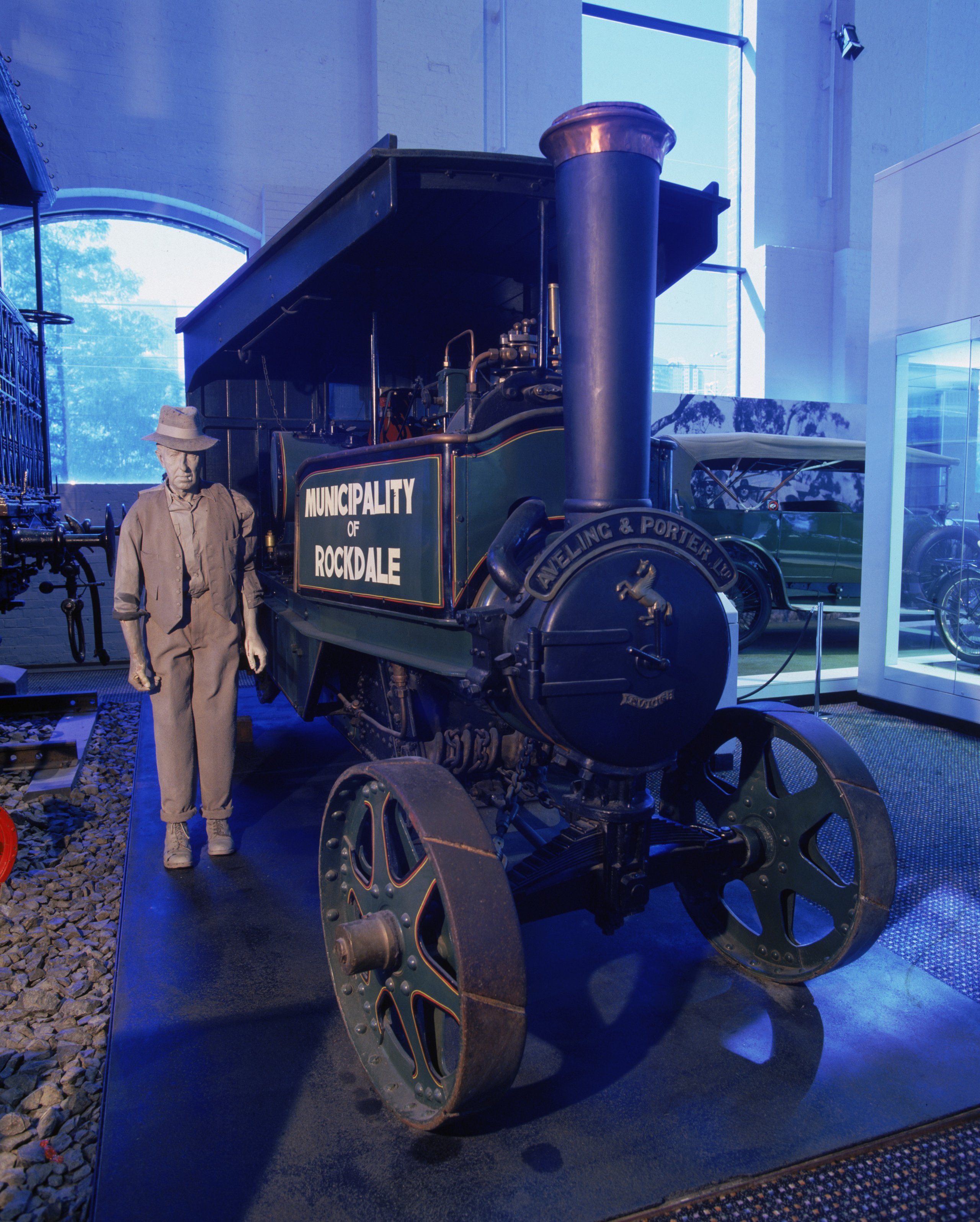

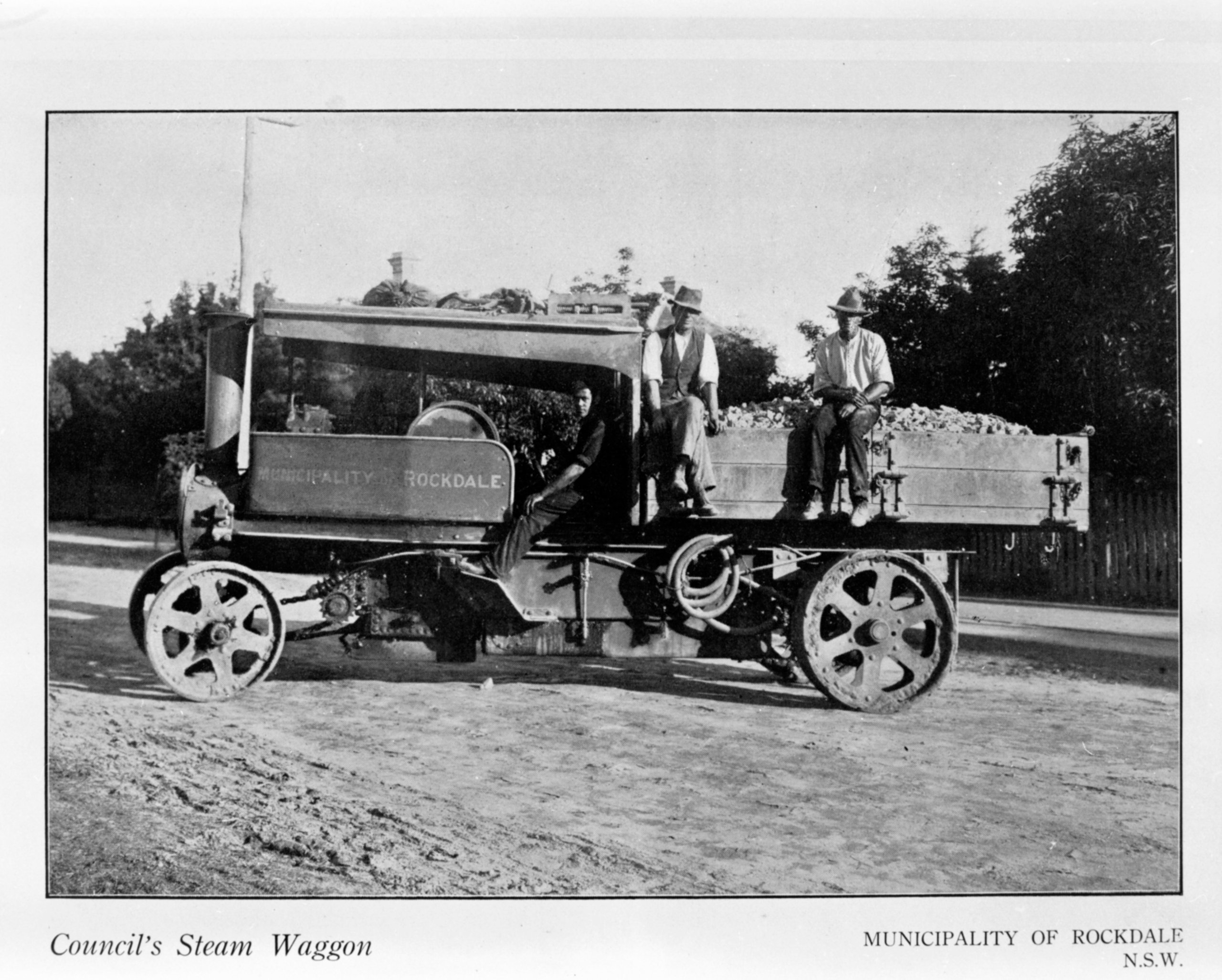

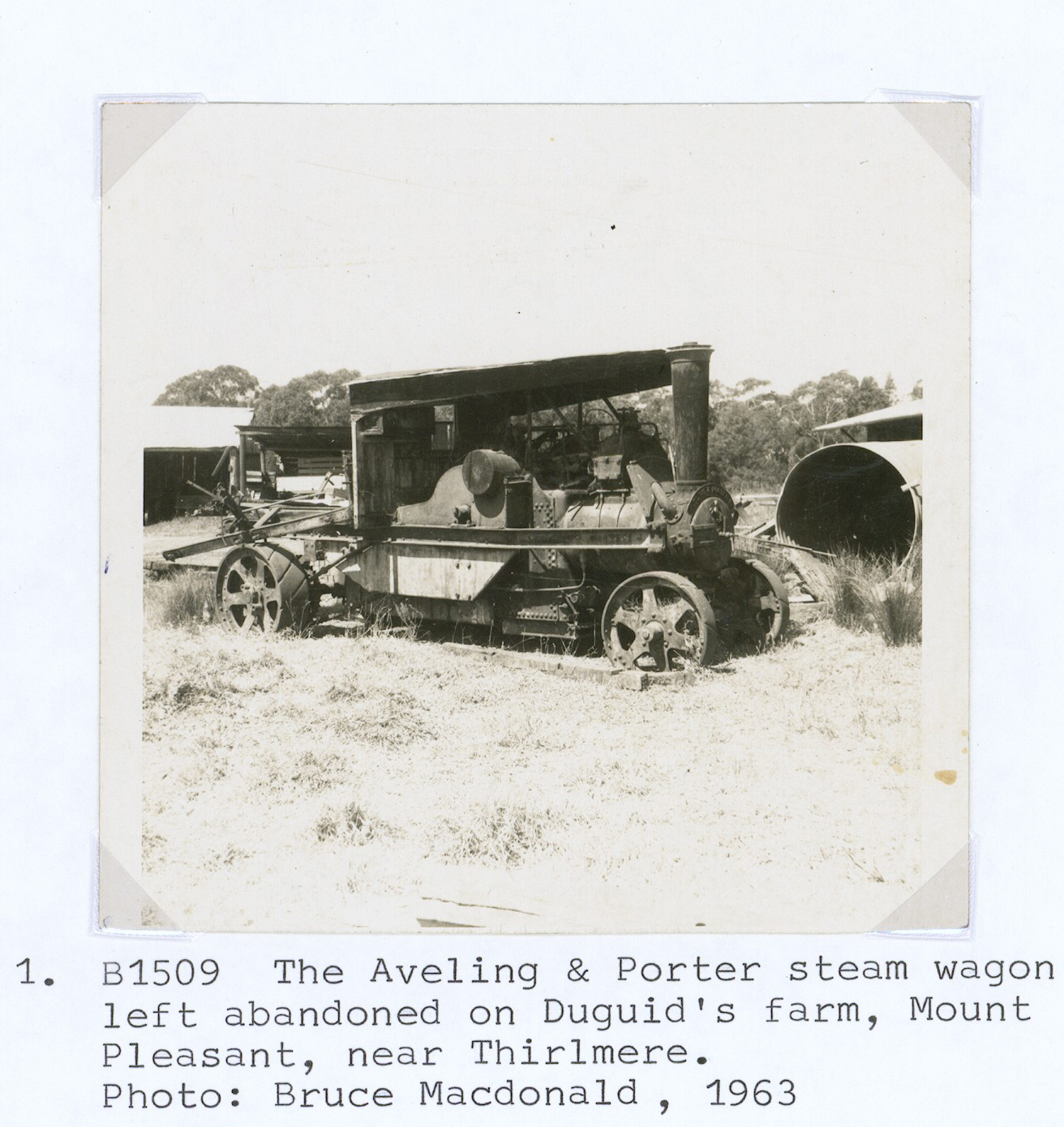

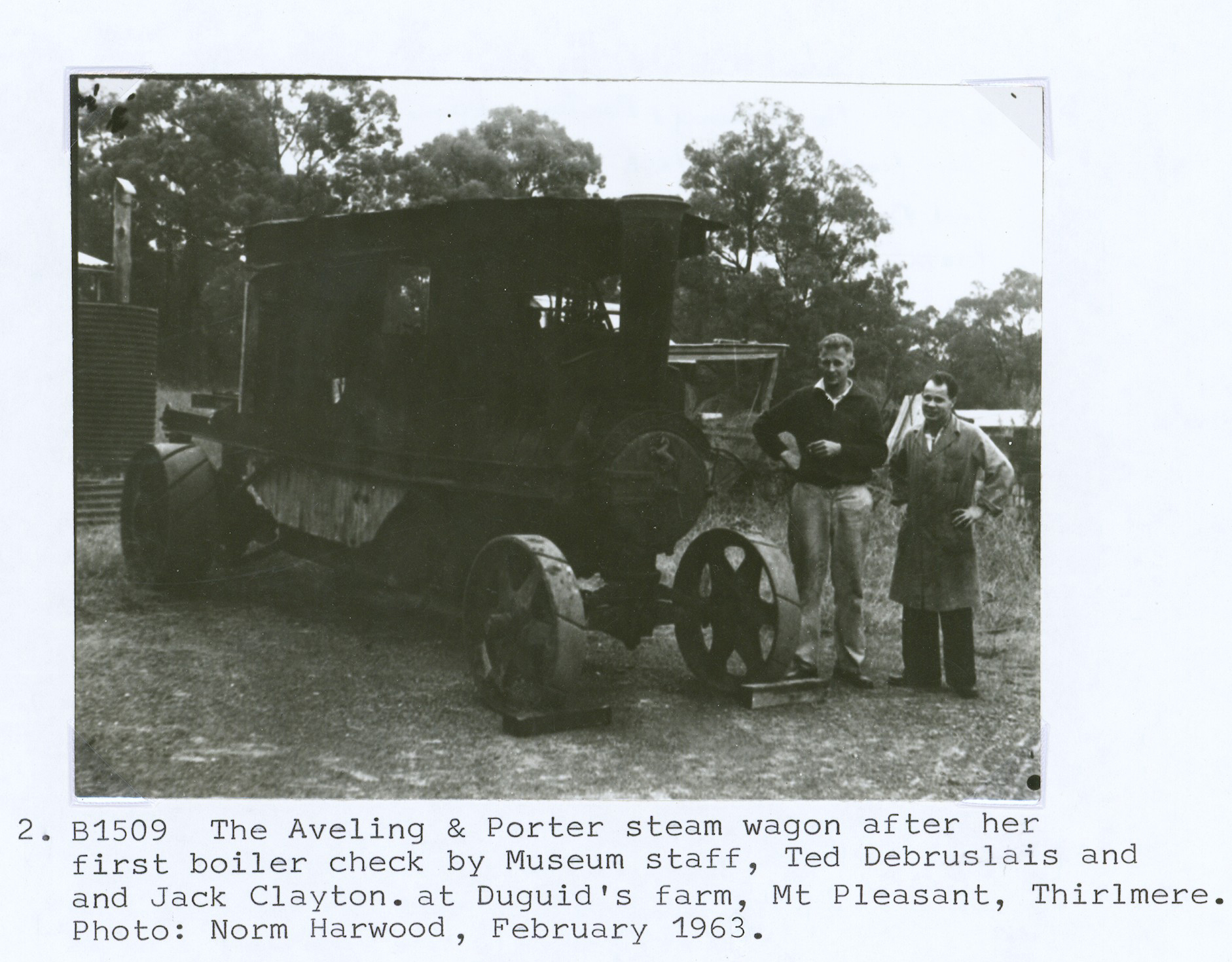

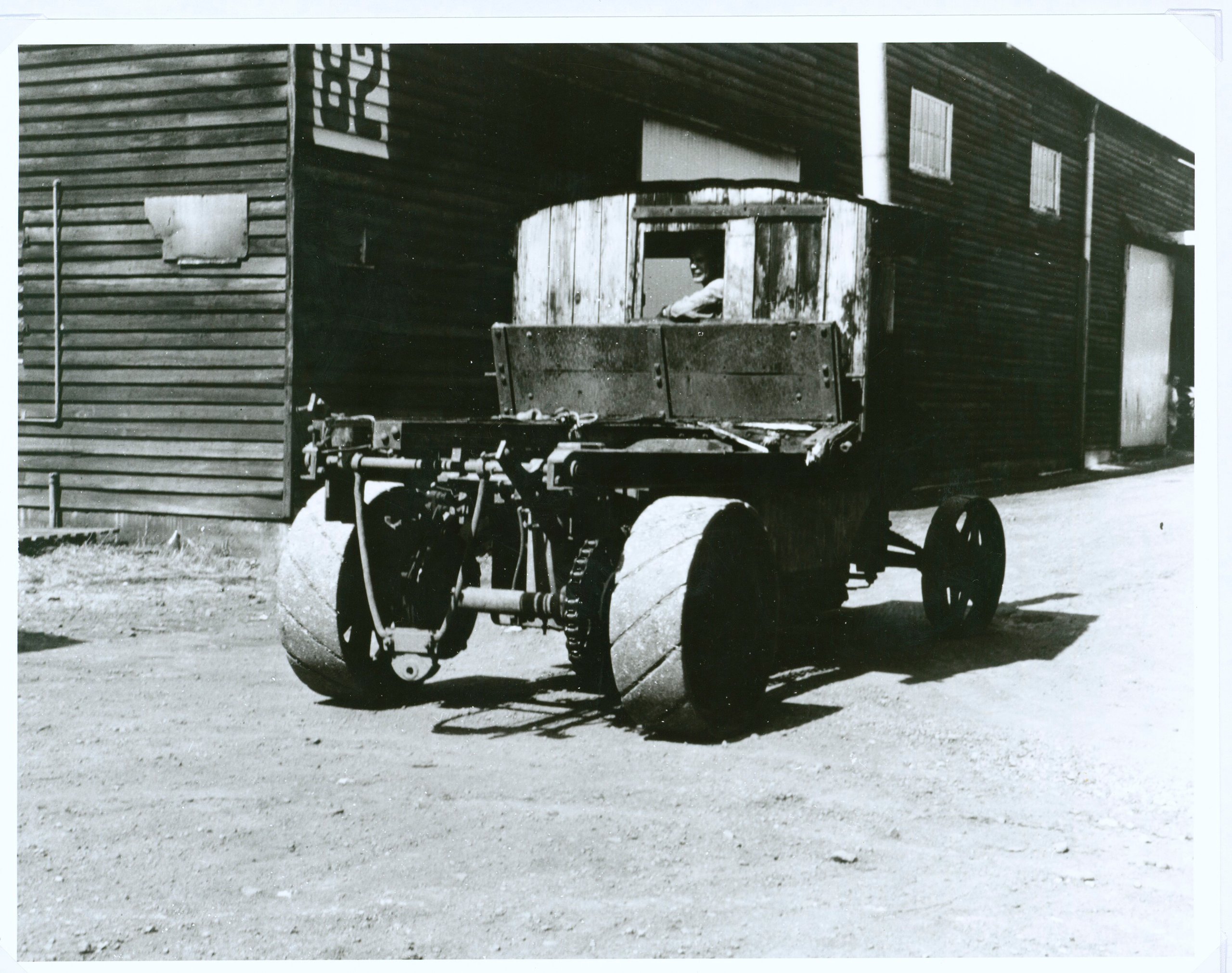

This steam wagon was made in England and used by Rockdale Council, in southern Sydney, as part of the equipment for making and repairing roads in the 1920s. It was a great improvement on the horsedrawn vehicles then in use as it could haul approximately four times the load. It was used to cart various materials including rock, blue metal and blocks of sandstone curbing for road building and surfacing within the municipality. From the late nineteenth century to the first decade of the twentieth century the steam wagon was the accepted machine for road haulage in the 5 ton and over class and a serious challenge to its internal combustion engine rival. However after the considerable use of motor lorries by the British Army during World War I and the subsequent surplus at the end of the war, the popularity of the steam wagon began to diminish. The Museum's overtype steam tip wagon was built in 1920 by the English company famous for their road rollers, Aveling & Porter of Rochester in Kent. It has builder's number 9247 and is known as a Type FGR. The steam wagon was dispatched from London to Rockdale Council and operated there in conjunction with several horsedrawn tip wagons and a steam roller. The steam wagon was operated by a qualified driver who had both a driver's licence and steam ticket. He was aided by an "offsider", usually a labourer, who not only shovelled out the load but helped the driver stoke the firebox and grease and oil the wagon. Daily coke consumption was about five 70 to 80 pound bags which were carried on the canopy roof. The 150 gallon water tank would last about two to three hours depending on the work. It then needed to be refilled from fire hydrants in the street, if water was laid on, or from creeks if working out of town. The steam wagon was in operation on the road five days per week but on Saturday mornings remained in the council depot where the firetubes were cleaned out and the oil reservoirs filled. In about 1924 Rockdale Council ordered two new steam wagons made by the Sentinel Wagon Works at Shrewsbury, England. These were undertype wagons with vertical boilers and were a great improvement on the Aveling & Porter wagon as they used less coke and operated at a higher speed. In about 1926 Council sold the steam wagon to Mr W. Duguid for use on his property at Mt Pleasant, near Thirlmere, NSW. It was used for hauling timber, pulling out tree stumps and driving machinery on the farm until 1946 before being discarded for a conventional tractor. The Museum was informed of the wagon's location in 1962 and after an inspection by staff members the owners agreed to donate the wagon. However, the problem of transporting it had to be overcome as the wagon had been left abandoned on a hillside which was unapproachable by a low loader as it could only be reached via a narrow unmade road with a hairpin bend. It was necessary to repair the wagon sufficiently to enable it to be steamed down the mountain under its own power to reach the low loader. Once safely in Sydney, the steam wagon was placed in storage until 1984 when it was restored to steaming condition and displayed in the Transport exhibition of the Museum from 1988 until 1999. It has subsequently been steamed at various rallies in New South Wales and Victoria. Of the 292 Aveling & Porter steam wagons built between 1909 and 1925 only four are known to survive worldwide. Margaret Simpson Kelly, Maurice A. "The Overtype Steam Road Wagon", Goose & Son Ltd, Norwich, England, 1971. Clark, Ronald H., "The Development of the English Steam Wagon", Goose & Son Ltd, Norwich, England, 1963. Simpson, Margaret, 'The Restoration of an Aveling & Porter Steam Wagon', in "Steam Restorer: N.S.W. Steam Preservation Co-op Society Ltd", Vol. 15 No.1, March 1985.

Loading...

Summary

Object Statement

Steam tip wagon, overtype, full size, Type FGR, serial number 9247, boiler test number 8273, metal / timber, made by Aveling & Porter Limited, Invicta Works, Rochester, Kent, England, 1920, used by Municipality of Rockdale, New South Wales, Australia

Physical Description

The steam wagon is an example of an overtype steam wagon in that it has a traction engine locomotive-type boiler with the cylinders and valve gear mounted on top of the boiler. The boiler is a Belpaire locomotive type which operated at a maximum steam pressure of 200 p.s.i. It is fitted with Aveling patent safety-valves and mountings. The engine features compound cylinders and slide valves controlled by Stephenson-Howe link motion. The link motion and the drive to the road wheels is taken through countershaft gearing to a long roller chain which drives the rear axle via a differential gear. The rear wheels are perforated and staked (steel strips diagonally riveted on to act as "tyres". The steam wagon has two road speeds with gears to reduce the top speed from 6.3 m.p.h. to 5 m.p.h. The two-way tipping mechanism is hydraulically operated and is controlled by a three-way cock on the output side of the standard Aveling feedwater pump. The steam wagon was ordered from the manufacturers without a body, which was subsequently constructed in Australia. The tip tray is spotted gum finished in dark grey and was probably lined with steel to enable rock and gravel to be carried. The canopy over the cab extends over the cylinders almost to the chimney, and paint-impregnated canvas was applied to the roof of the canopy to protect it against the weather. The wagon is finished in green and black. Specifications Type : FGR Cylinder: Compound (slide valve type) Cylinder bore: 3.75 in. (95 mm) and 6.125 in. (155 mm) Cylinder stroke: 6 in. (152 mm) Boiler: Belpair type, locomotive Boiler barrel: 1 ft 9.75 in. (552 mm) diameter Boiler heating surface: 52 sq. ft. (15.8m²) Boiler grate area: 2.73 sq. ft. (0.83m²) Rev. per minute of crankshaft : 300 (31.5 radian per second) B.H.P.: 20½ Weight empty: 6 tons (6.5 tonnes) Weight loaded: 9 tons (9.9 tonnes) Tipper body length : 10 ft (3048 mm) Tipper body width: 7 ft (2133 mm) Tipper body depth: 1 ft 6 in. (457 mm) Flywheel diameter: 2 ft (609 mm) Working Pressure: 200 lbs per sq. in. (1378 kPa) Front wheels: 2 ft 9 in. diam. by 6 in. wide (838 mm x 152 mm) Rear wheels: 3 ft 3 in. diam. by 12 in. wide (990 mm x 304 mm) Road speeds: 2.18 mph & 5 mph (3.5 km/h & 8 km/h) Wheelbase: 13 ft 6 in. (4114 mm) Overall Length: 19 ft 9½ in. (6032 mm) Overall width: 6 ft 8 in. (2032 mm) The export directions stencilled on the wagon comprised: 'A P N / H 1303 / SYDNEY / 7494'. Additional information added 2011 Steam for the wagon is generated in a locomotive-type Belpair boiler with grate area of 2.73 square feet and heating surface of 52 square feet. The boiler is fitted with Aveling patent safety-vales and mountings and the engine features compound cylinders of 3.75 and 6.125 inch bore by 6-inch strokes, with slide valves controlled by Stephenson-Howe link motion. The engine originally operated at 300 rpm and 200 psi. The drive from the engine to the road-wheels is taken through countershaft gearing to a long roller chain which drives the rear axle via a differential gear. The diameter of the rear axle shaft is 4.5 inches and steering is by chain. Braking is on the rear wheels only and is of the screw-down, external contracting type on the live axle. The fore-carriage is suspended on transverse leaf springs while the rear end has semi elliptic springs. These are shackled to pins which are free to slide in slotted brackets when deflected by the load. The road wheels are of perforated plate with iron tyres, the rear ones being straked for greater adhesion. Aveling & Porter steam wagons were capable of two road speeds, 6.3 mph. and 2.18 mph. However, the Museum's wagon was ordered with special reduction gears to reduce the top speed to 5 mph. Channel framing along the sides of the wagon carries all the gear, radius rods and water tank. The two-way tipping mechanism is hydraulically operated and controlled by a three-way cock on the output side of the standard Aveling feedwater pump. The tray, cab and canopy are of timber. The tray is double-hinged on the sides and the rear flap is hinged at the top. The canopy over the cab extends over the cylinders almost to the chimney and has two small holes to drain rainwater. A covering of paint-impregnated canvas protects the timber roof from weather. The wagon was originally fitted with kerosene lamps attached to brackets on either side of the smokebox door while a particularly quaint feature is the foot-operated warning bell located beneath the driver's footrest.

DIMENSIONS

Height

2200 mm

Width

2000 mm

Depth

6100 mm

PRODUCTION

Notes

In the late nineteenth century and the first decade of the twentieth century the steam wagon was a serious competitor to its internal combustion engine rivals. Prior to the First World War, steam wagons were the accepted machines for haulage in the 5 tons and over class. The first steam wagon, known as a "steam cart", was designed by P.J. Parmiter, a manufacturer of agricultural implements at Tisbury, Wiltshire, England, and patented in 1880. In 1898 Parmiter's design was manufactured by Messrs Mann and the pioneer overtype steam wagon was born. The manufacture was influenced by the passing of the 1896 Motor Car Act and the subsequent trials held by the Liverpool Self-propelled Traffic Association. From these trials emerged a distinct variety of steam wagon, which although popular for twenty-five years, were made only in Britain. The vehicle was known as an 'overtype' wagon, because the engine was mounted on top of a short locomotive boiler, in a similar manner to a traction engine. This steam wagon was built in 1920 by Aveling & Porter Limited at their Invicta Works, at Rochester, Kent, England, with builder's No. 9247. The Aveling & Porter company was renowned for its invention and manufacture of road rollers, of which this Museum also has an example. The company was founded by Thomas Aveling who was born at Elm, Cambridgeshire, in 1824. As a young man he moved to Kent where he founded a small agricultural engineering business in Rochester, in 1850. The first traction engine made in his works appeared at the Leeds Show in 1861, and in 1865 he produced the world's first road roller constructed in its familiar form. Progress in design was rapid, and within a decade the general steam roller appearance was accepted. In 1862, Thomas Aveling was joined in partnership by Richard T. Porter and the company was then known as Aveling & Porter. Like many other traction engine builders, Aveling & Porter entered the wagon business and despatched their first overtype steam wagon on 1909. Two models were offered, the type FGR 3- ton wagon, whose payload was later increased to 3-4 tons, and the type FGP 5-ton wagon. The Aveling wagon followed the usual overtype configuration, with a 3-ton locomotive boiler. One interesting constructional detail of these boilers was the elimination of crown stays in the firebox. This was achieved by tying the inner and outer flat crownplates by rows of screwed stays. The first tipping body supplied by the company was mounted on the wagon that had works No. 7951, dispatched in 1913. This was a manually operated screw type. On 3 August 1915 Aveling introduced their first hydraulically operated tipping system in wagon No. 8618. In all 292 steam wagons were built by Aveling & Porter and production of wagons ceased in 1925. Twelve of them were erected from parts supplied by Avelings to Messrs Richard Garrett Ltd of Leiston when the two firms were embraced by the abortive Agricultural and General Engineers Ltd combine. The works numbers of these twelve were consecutively 9270-9282 less No. 9281. The final wagon built at Rochester, No. 11111, had a boiler made by Garretts and was delivered on 14 January 1925. The last wagon sent out was No. 9452 on 30 November 1925. The decline and eventual cessation of steam wagon manufacture was largely influenced by the choice made by the British Army during the First World War to employ mostly internal combustion engine motor lorries. Some of these were built in Britain and some in America. The advantages of these motor lorries were that they were lighter, used less bulky fuel, required less attention for operation and were easy to get on the move at short notice. After the war, surplus motor lorries became available in Britain at low cost. Of the 292 Aveling & Porter steam wagons built only four are known to survive.

HISTORY

Notes

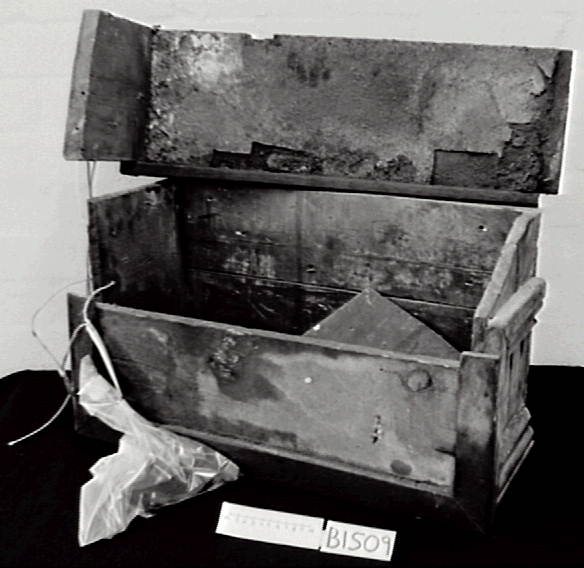

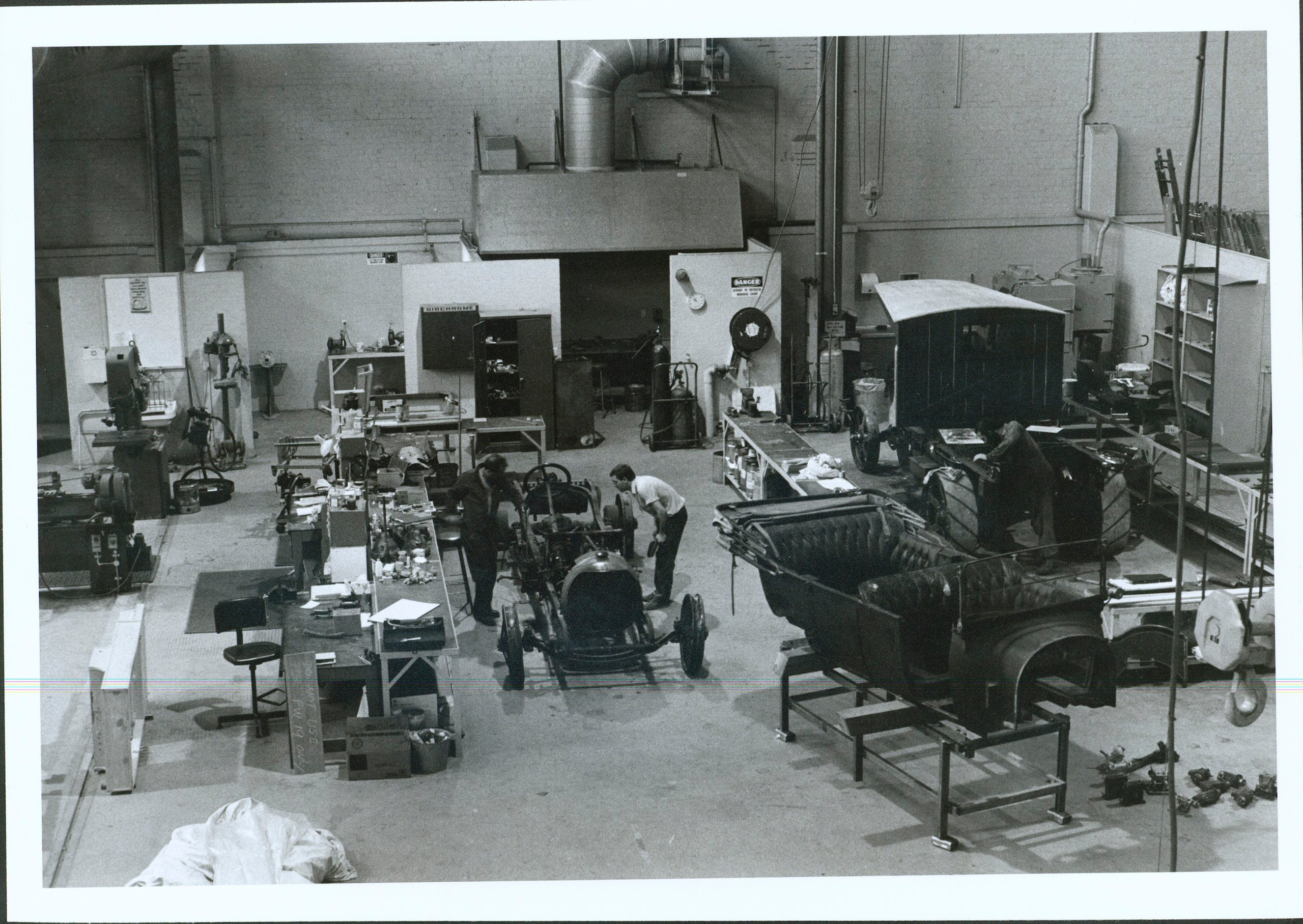

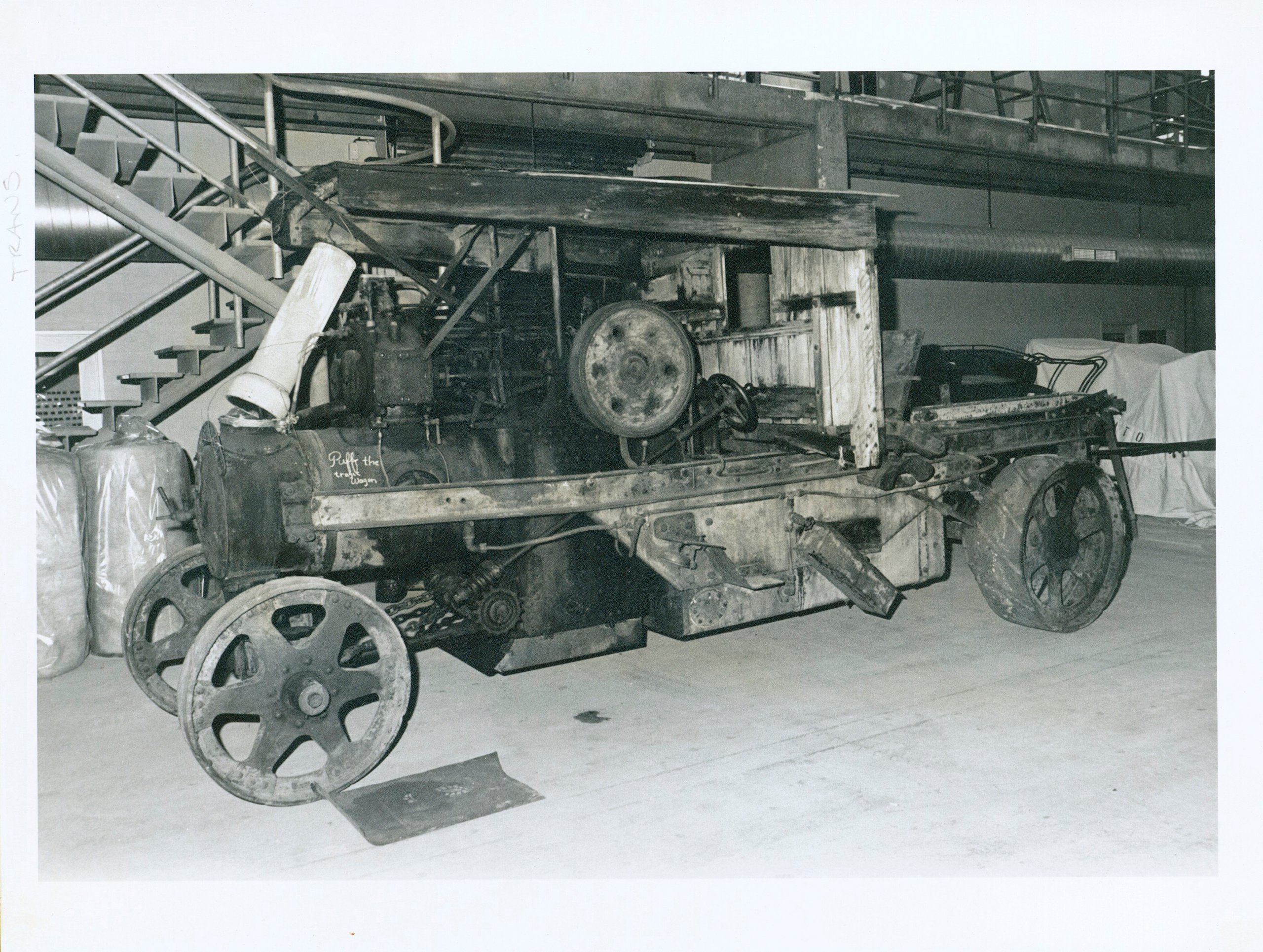

The Aveling & Porter steam wagon was dispatched to the Municipality of Rockdale, in Sydney, on the 25th September, 1920, through the shipping agents, James Pollock, Sons & Co. Ltd., of London. Aveling & Porter company records also show that the wagon was ordered without any timber bodywork. As the timber is mostly of Australian native types, this confirmed that the cab, canopy and tray were locally built, probably in Sydney. The vehicle was the first steam wagon to be used by Rockdale Council and, despite its slow speed, was a vast improvement on the horse-drawn tip wagons then in service. Some of the steam wagon's duties included hauling rock, sand and gravel for road construction and sandstone blocks for curbing. The wagon was operated by a qualified council driver, aided by an "offsider", usually a labourer, whose duties included helping to shovel out the load, stoke the firebox, and oil and grease the wagon. The driver's day started at about 6.30 am and it took about an hour to get the wagon steamed up and ready for the job. First, coal in the firebox from the night before was raked out and the new fire started from kindling. Following this, wood was applied and finally fine coal of 0.75 inch to 1.5-inch grade was added. Once underway similar grade coke was used for the rest of the day, except for when the wagon had been idle for a couple of hours and coal was used to restart the fire. Daily fuel consumption was about five bags of coke, all carried on top of the wagon's roof. The driver also checked the water tank level, and this was topped up if necessary at the council yard. The 150-gallon capacity water tank would last two or three hours depending on the work. Refilling during the day was undertaken at street hydrants, or from creeks when working out of town. Weekly maintenance on the wagon was carried out on Saturday mornings by the driver who would clean out the fire-tubes. During the early 1920s Rockdale Council ordered two Sentinel undertype steam wagons, built in Shrewsbury, England. The Sentinels were an improvement on the Aveling wagon because they used less coke and operated faster. After finishing with the council in the mid-1920s the Aveling & Porter wagon apparently was sent out to work at the mines at Cobar, in western NSW, before ending up in a second-hand machinery yard back in Sydney in about 1929. It was then purchased by Mr W. Duguid for use on his farm at Mt Pleasant, near Thirlmere, 84 km SW of Sydney. The wagon was sent by rail to Thirlmere and unloaded at a siding used by a local timber mill, now the site of the current NSW Rail Transport Museum. As Mr Duguid's brother wrote to the author in 1985 "We got the wagon unloaded, the boiler steamed and on our way. [What followed were] three days of adventure taking the wagon three miles to our property [which can be] summed up in three words, amusement, vexation and satisfaction. The amusing part, children at the school ran out without permission lining the fence with mouths open to watch a strange engine running up the main street. The vexing part, about halfway to our property was a sandy strip of track 200 yards beside one of the Thirlmere Lakes. As soon as we hit the sand everything came to a stop. The wagon could not be steered, so we had to go home and get the horse and cart and go into the railway station and see if the station master could put us onto a load of rail sleepers. There we had some luck, back to the wagon which we had to jack up to get the sleepers in below. Then the job of laying them in the front and lifting them at the back and so on. This took us two days and on the final day we got to solid ground where the wagon took off up a steep hill which included a very sharp hairpin bend which proved no trouble. At the top we changed gear and finished the journey at a reckless 5 mph." Duguid had been a marine engineer so knew how to keep the wagon in good order. It proved very useful for pulling up tree stumps, hauling timber to his sawmill and cutting it up, and driving machinery including a chaffcutter, a grist mill and emery wheel. The boiler also provided steam to clean and sterilize chicken brooding equipment and for a honey house, honey tank and extractors as honey had to be kept warm for straining. After excellent service Duguid discarded the wagon in 1946 for a diesel engine. In 1962 the Powerhouse Museum was notified of the abandoned wagon and the Duguid family agreed to its donation. The Museum was then faced with the problem of moving the wagon which had been left for 16 years on the Mt Pleasant farm in a fairly inaccessible location. After an inspection in 1963 it was discovered that a low loader could not be brought directly to the wagon site because of a narrow, un-made road and back down that tight hairpin bend. The only solution was to repair the wagon sufficiently to enable it to be driven under its own steam down the mountainside. Many hours were spent by Museum staff repairing the water tank, removing rust from all the moving parts, removing valve covers to clean and oil the valve spindles and refitting a new gasket to the boiler inspection cover. Next, the water tank and boiler were filled with water and a successful hydrostatic test carried out. The wagon was then chocked with railway sleepers, steam raised to half the tested pressure and the engine made to turn over for an hour before attempting to move. When the gears were engaged the wagon would not move, so more steam had to be raised. Two more hours of steaming at the increased pressure had to be done before the fire was drawn to undertake the journey. This time the wagon finally moved and steamed down the mountain, successfully negotiating the dreaded hairpin bend much to everyone's relief. On safely reaching the low loader at the bottom, the wagon was secured for the trip to Sydney. Research For about 20 years the wagon was held in one of the Museum's stores before the decision was made to restore it. The policy adopted was to restore the wagon as accurately as possible to within the first few years of service with Rockdale council. However, before that the wagon had to be thoroughly researched which involved corresponding with the original builders, and various steam experts in Britain as well as making personal contact with Australian steam enthusiasts. Specifications and photographs were researched from books, journals and reprints of contemporary company catalogues. One of the most difficult problems to overcome was the reconstruction of the tip tray, of which very little remained, and no timber on the sides or back was left to determine the exact configuration. Copies of overall drawings were obtained from England showing the tray arrangement of wagons built entirely by Aveling & Porter. However, this did not tally with the various hinges, bolts and chains which arrived with the Museum's wagon. Since the tray was locally built a determined search for photographs of the wagon was undertaken to work out the appearance of the tray. With great luck two photos were found depicting Aveling & Porter steam wagons in use at another Sydney council yard at Leichhardt in about 1920. The photographs were from the J.G. Park Collection, part of the Historic Photograph Collection at the Macleay Museum in the University of Sydney. Access to the fine-grained 10 by 8-inch glass-plate negatives enabled considerable enlargement which revealed the tray arrangement of the Leichhardt wagons was identical to the remaining pieces of ironwork on the Museum's Rockdale wagon. The puzzle had been solved and the reconstruction of the tray could proceed based entirely on the discovery and clarity of the historic photographs. One more problem remained however. The historic photographs were of course in monochrome so the correct colour and finish of the tray, cab and canopy were still unknown. Paint samples were examined under a microscope in the Museum's Conservation Department to analyse the various paint layers but the results were inconclusive. It was decided to make a public appeal in the "St George and Sutherland Shire Leader", the local newspaper in the area where the steam wagon had operated in Sydney. The response was excellent and 26 people contacted the Museum with all sorts of information. Two were particularly helpful, one man had driven steam wagons in Sydney in the 1920s while the other a horse-drawn tip wagon for Rockdale Council alongside the Museum's steam wagon in 1923. As a result of their assistance all the final problems of colour and finish were solved. A great deal of invaluable oral history was also obtained regarding the operation, maintenance and social history surrounding the steam wagon at Rockdale. Restoration The complete restoration of the wagon to steaming condition was largely undertaken by Museum staff in our large workshop. The wagon was fairly complete except for the water tank, fire bars, smokestack, tray, cab, cab support brackets, engine side guards, lock bar, smoke box, suction hose and ball, and the manufacturer's plate which all had to be replaced. To start with the wagon was dismantled and all "bolted on" items removed except for rivet joints, which were not disturbed unless necessary. The boiler was chemically cleaned and de-scaled then sandblasted inside and out. The fire-tubes were removed, and tests carried out on the shell, firebox, rivets and seams. Luckily no major damage or corrosion was found. The boiler was then re-tubed and hydrostatically tested and inspected by a boiler inspector, re-sandblasted and finally painted with Dulux Hi-Temp 600. The engine was stripped down, cleaned and thoroughly examined. Very little wear was found except for the valve rods which were ground down, hard chromed then reground to size. The frame, wheels, axles and all small painted parts were bead blasted, primed, undercoated and given two topcoats of paint by brush. The gear selection yoke was repaired, and the drive chain sprocket replaced. The water tank was beyond repair so a new tank was made up and riveted by the Sydney Maritime Museum. This was then bead blasted to remove mill scale, primed and also given an undercoat and two topcoats of paint. The water pump plunger and drive gear bush were badly worn, so replacements were made and fitted. It was found that the front wheel bushes were badly worn and had to be replaced. These were turned out of bronze cored bar and fitted together with new felt seals. The rear wheel bearing housings needed to be pad welded and re-machined. Cracked bronze slippers were repaired and refitted while the rear wheel pin holes were bored oversize, fitted with a sleeve and then welded into place to return them to standard size. The steering auger was bent and had to be straightened and the worm and worm wheel were worn. Consequently, a new worm was made, and the worm wheel built up and re-machined to match. All bushes in the steering assembly needed replacement and in some cases the castings were bored, sleeved and excess play removed. All brass and copper pipework, valves and fittings were degreased, cleaned then polished by hand. The fire-door required a new baffle and this was made, fitted and riveted into place and a new ash pan and fire bars were made. The smoke box door locking mechanism was missing. With the aid of sketches supplied by the only other owner of a complete Aveling & Porter steam wagon in Australia, a 5-ton type PGP tip wagon No. 7758 built in 1912, a suitable replacement of 0.75 inch by 4.0 inch flat bar was made. A rubbing of the builder's plate from this wagon was also obtained to make up a replica for the Museum's plate. The original timber work on the wagon was analysed by the Forestry Commission of NSW who reported that the boiler lagging slats were Larix SP (Larch), the tray and cab rails were Eucalyptus Maculata (Spotted Gum) and the cab planks were Agahis SP (Kauri). Since the cab canopy and tray were rotten and in some cases non existent, these had to be made up. The canopy roof was painted and while still wet was covered with canvas. The cab and tray were primed, undercoated and given two top coats of Dulux Charcoal while the canopy roof was finished in Dulux Biscuit. The cab was then lowered in place and the tray bolted together using similar coach bolts made to the original design. It was necessary to have all but two of the original hinges remade to the same design by a local blacksmith. The chimney stack also needed replacing due to corrosion. It was rolled from16 gauge mild steel and hand riveted using mild steel rivets. The copper bezel was beaten back into shape and hand riveted on with copper rivets. A new front stay also had to be made up which was fabricated from steel pipe and plate. Two new toolboxes were built using the original materials and specifications. One was of 16-gauge mild steel and fitted to the outside of the wagon and the other was timber (spotted gum) and fitted inside the cab. The safety valves required stripping, cleaning and relapping with new springs and they were set to blow off at 100 psi. The steam gauge glass on the wagon was broken and a new, but obsolete, glass was found which had to be ground down to size before fitting. The rear brake had to be re-aligned to the drum and one strut and four pins needed replacement. The drive chain was partly worn but as the size is no longer manufactured it was decided to leave the chain as it was. The final step in the restoration was to undertake a test fire. The unit was filled with water and gas was used to fire the boiler. However, it was found that a proper fire of coke was needed to supply the necessary heat. After a number of successful steamings the wagon was put on permanent display as one of the highlights in the Transport exhibition of the Powerhouse Museum from 1988 until 1999. For some years after that it was regularly steamed at rallies including Steamfest at Maitland, NSW, and is still operational. The Powerhouse Museum has undertaken the restoration of a number of transport objects over the years but it is considered that this one was the most sympathetically done because of the completeness of the existing wagon, the extensive research undertaken and the care involved to ensure the authenticity of the replaced components. This was largely achieved through the use of original photographs of the wagon while in use during its early working life. Margaret Simpson Curator, Science Technology & Industry, updated 2011

SOURCE

Credit Line

Gift of Mr W Duguid, 1962

Acquisition Date

21 March 1963

Copyright for the above image is held by the Powerhouse and may be subject to third-party copyright restrictions. Please submit an Image Licensing Enquiry for information regarding reproduction, copyright and fees. Text is released under Attribution-Non Commercial-No Derivative licence.

Image Licensing Enquiry

Object Enquiry