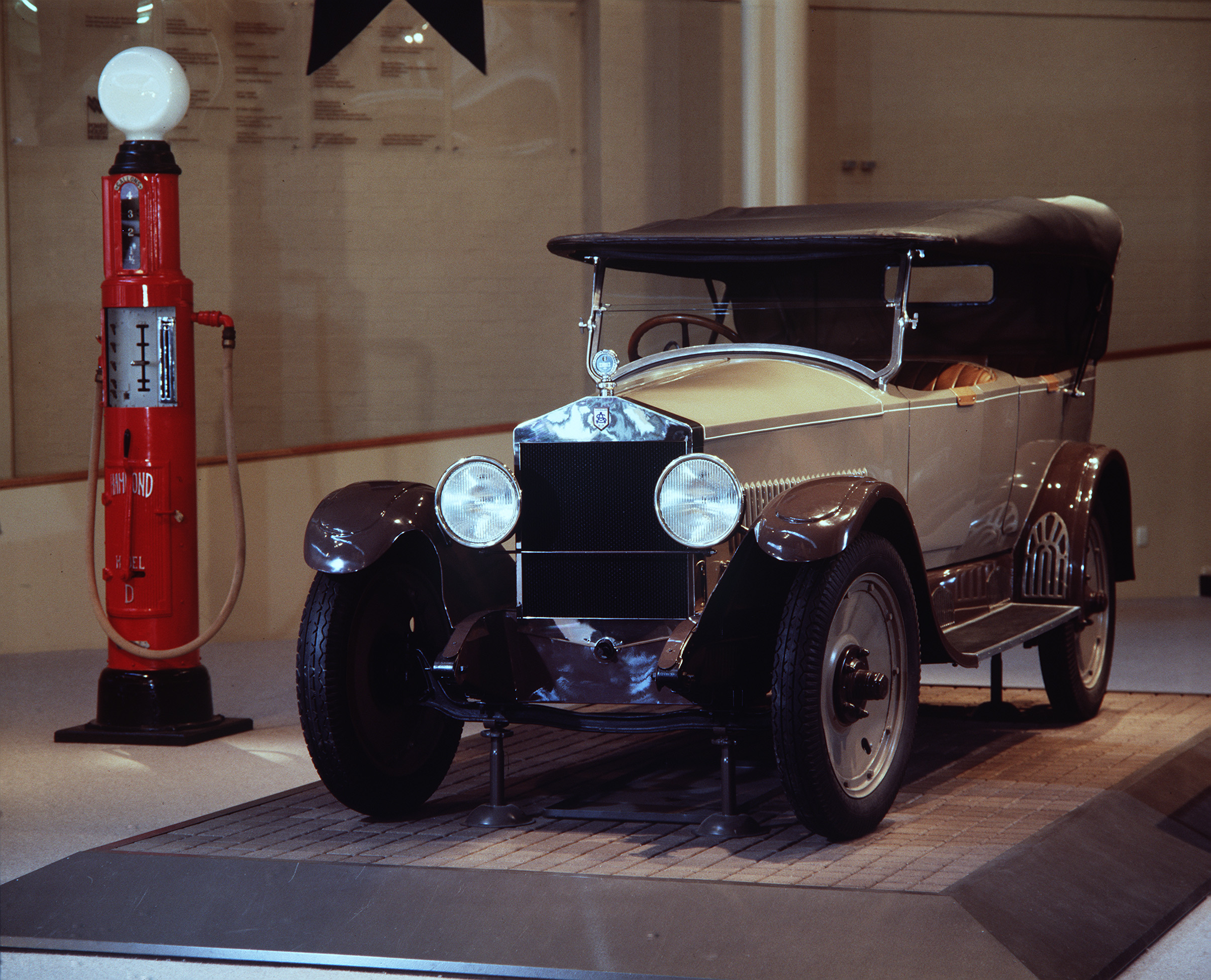

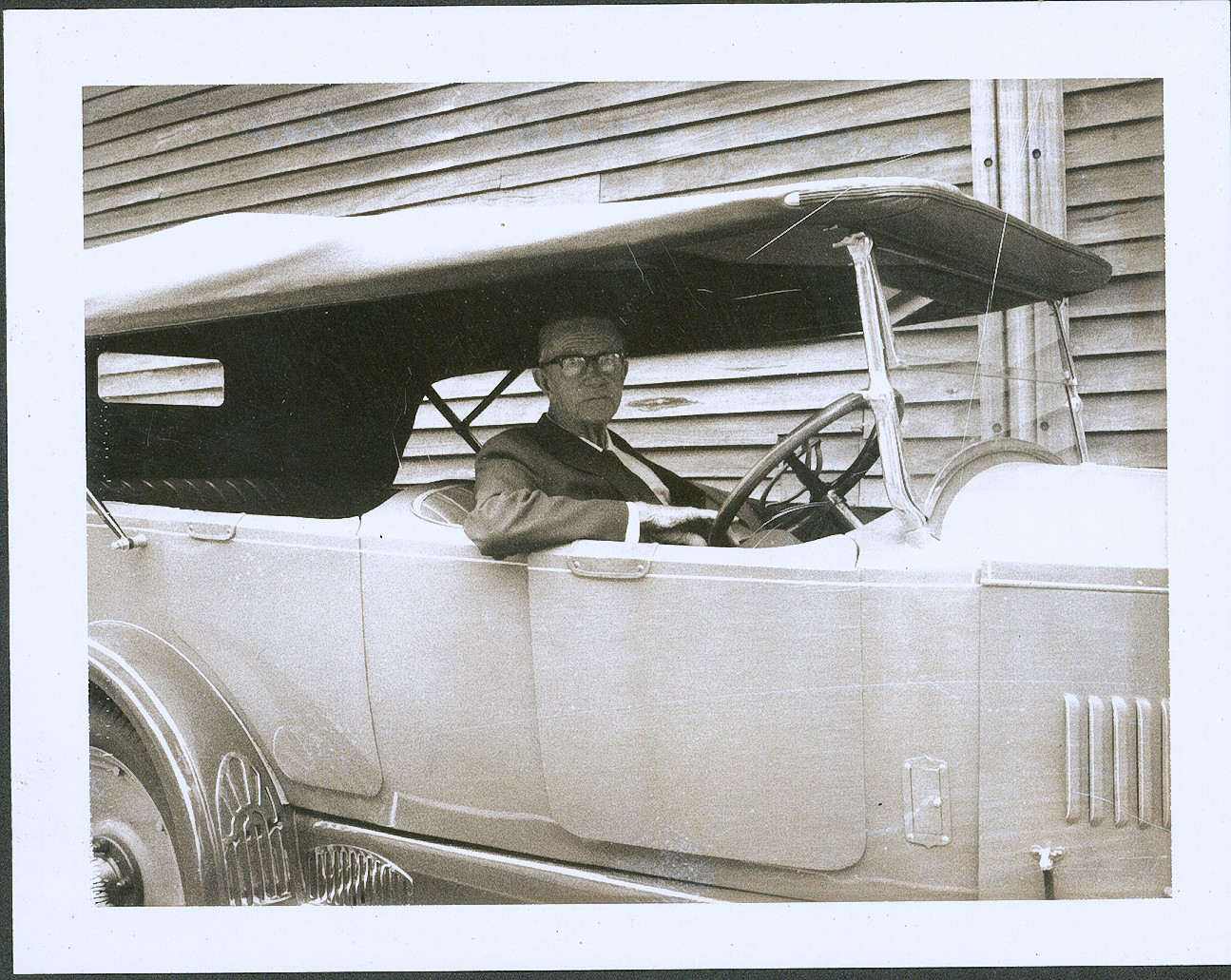

1923 Australian Six model H23 tourer

Object No. B1507

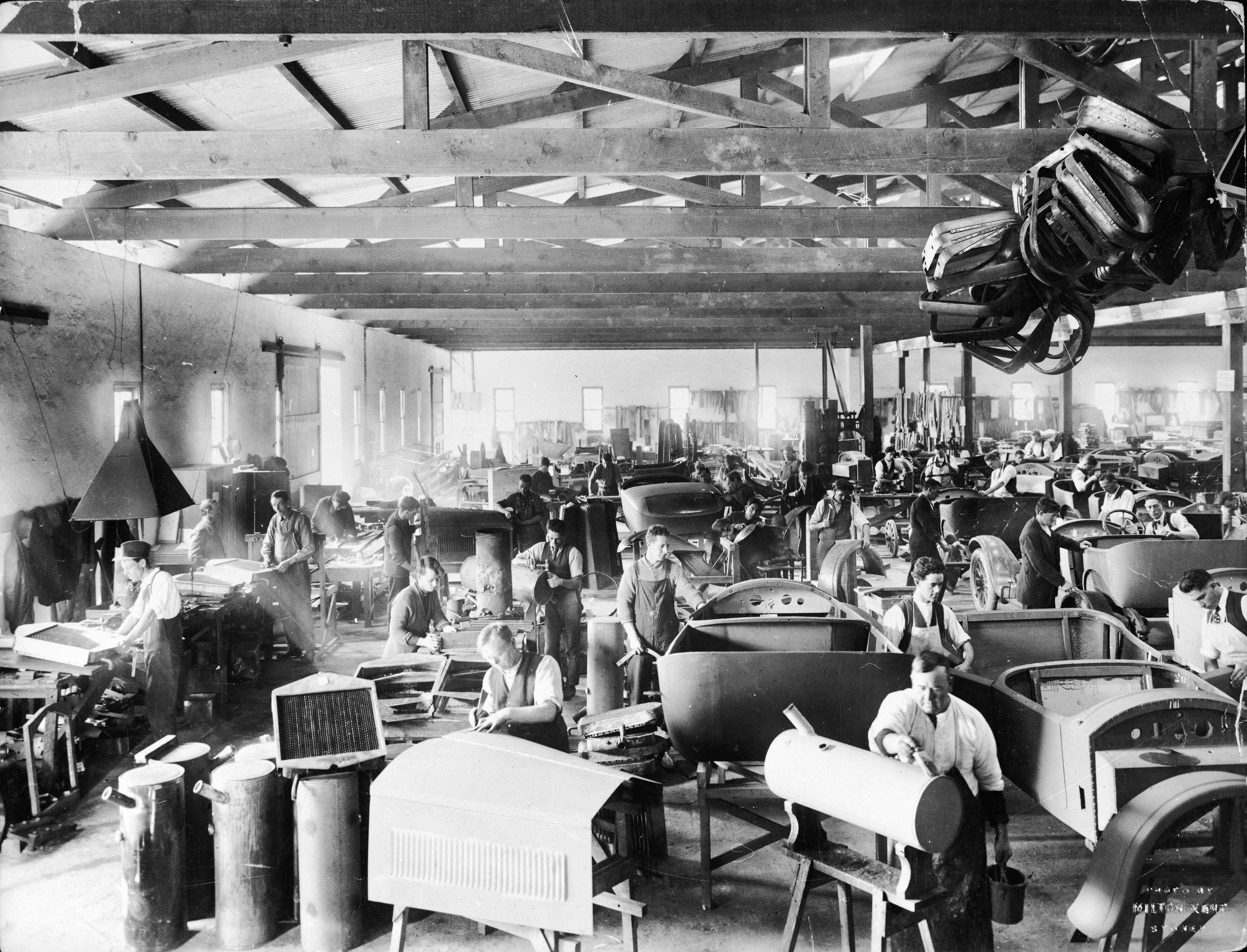

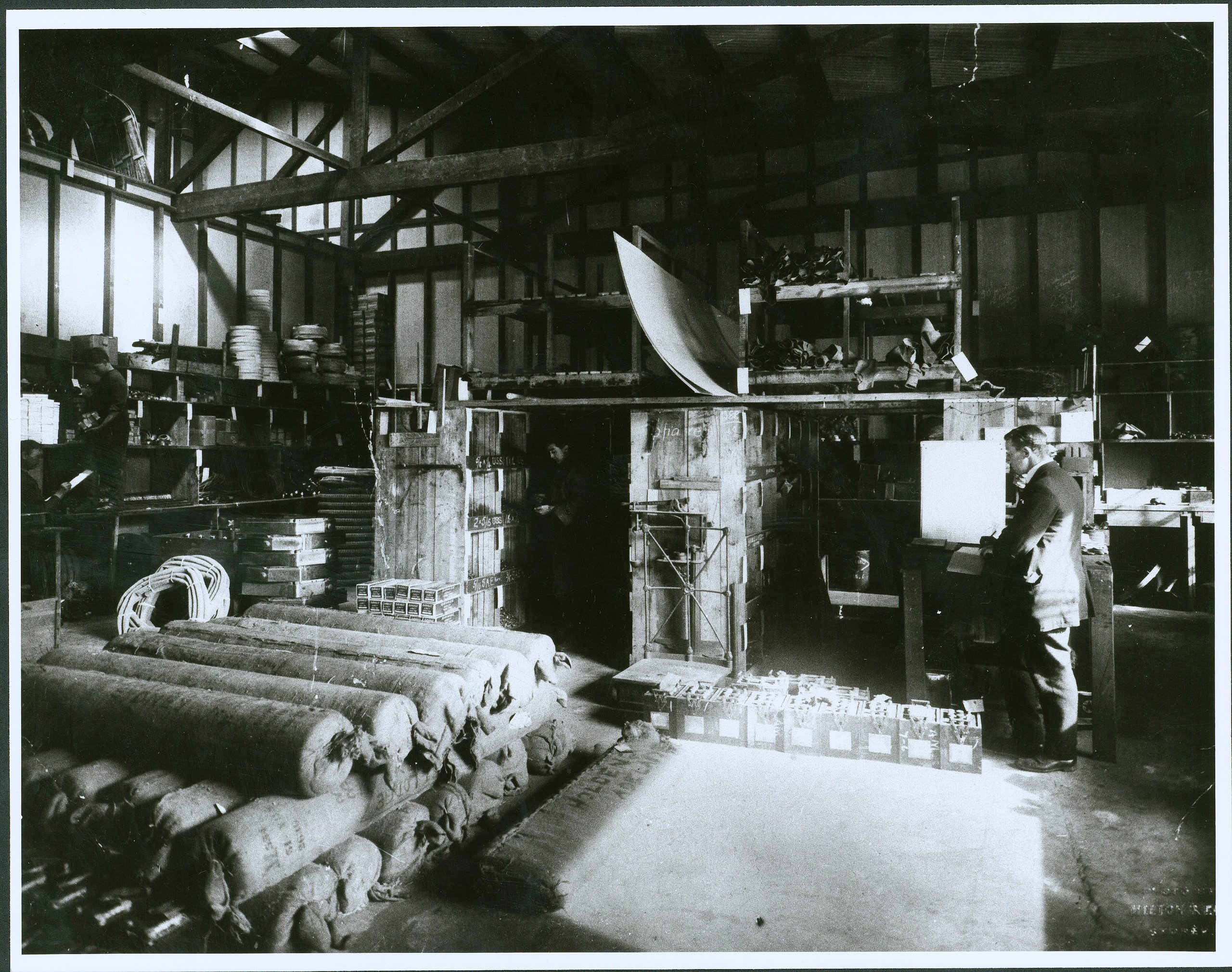

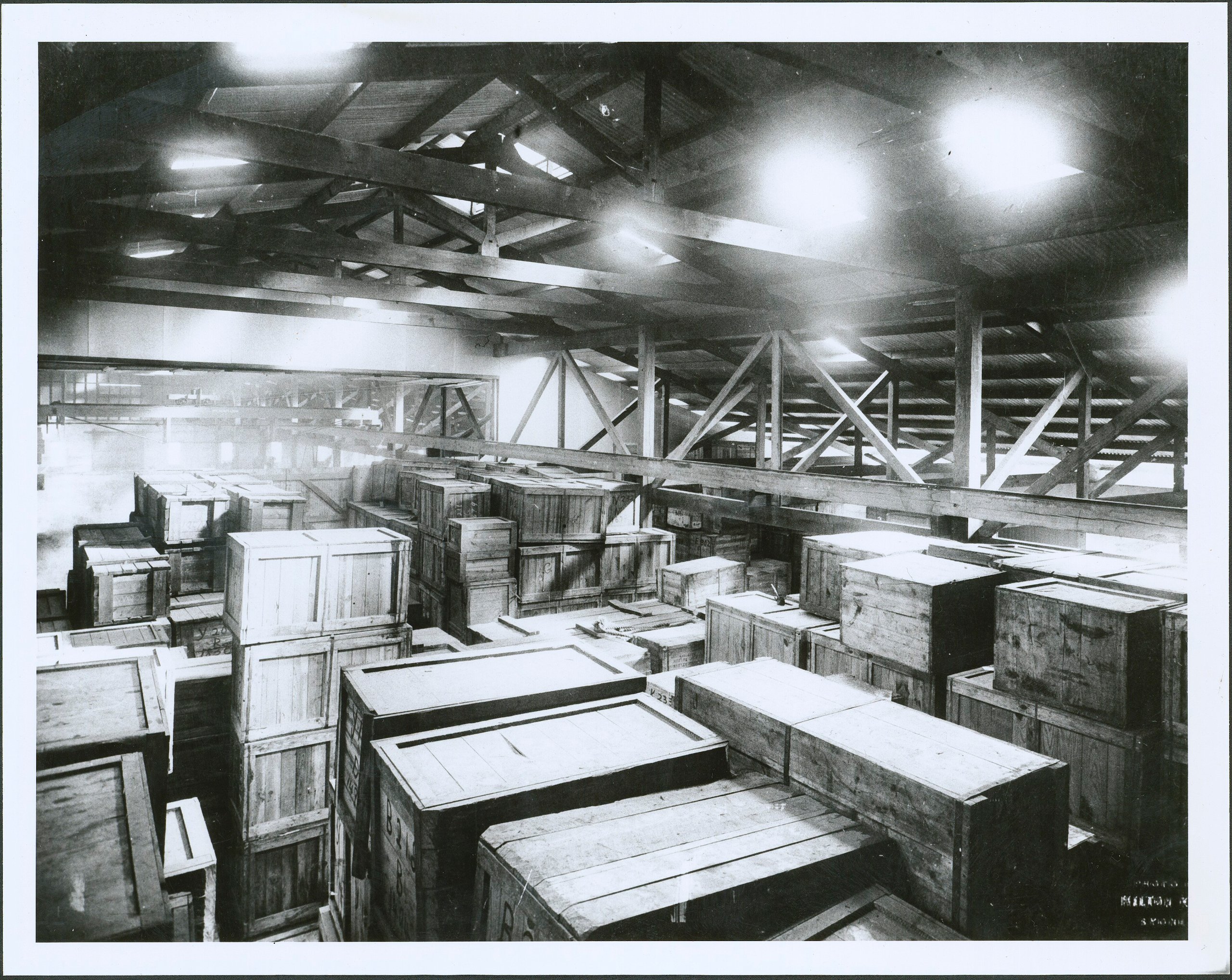

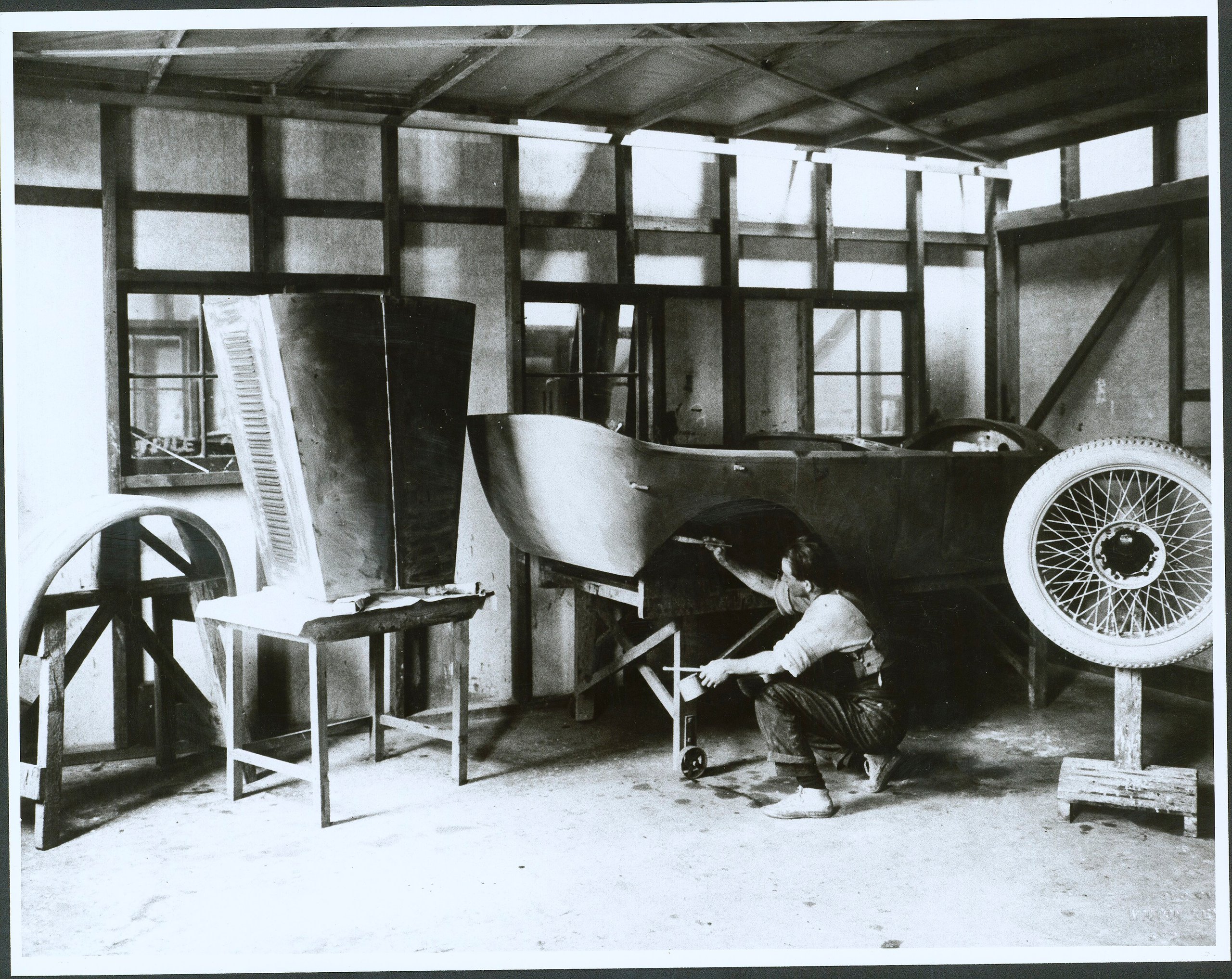

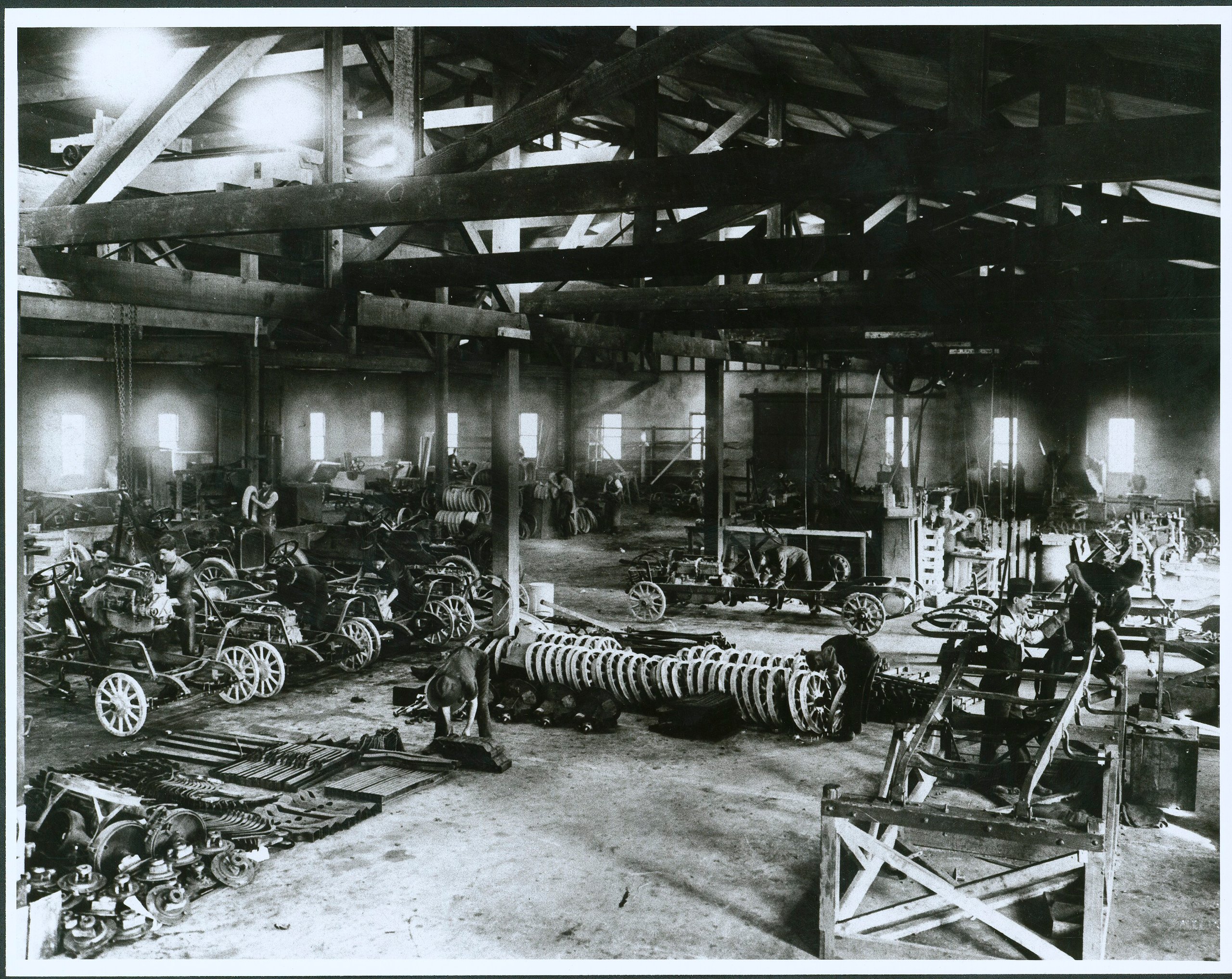

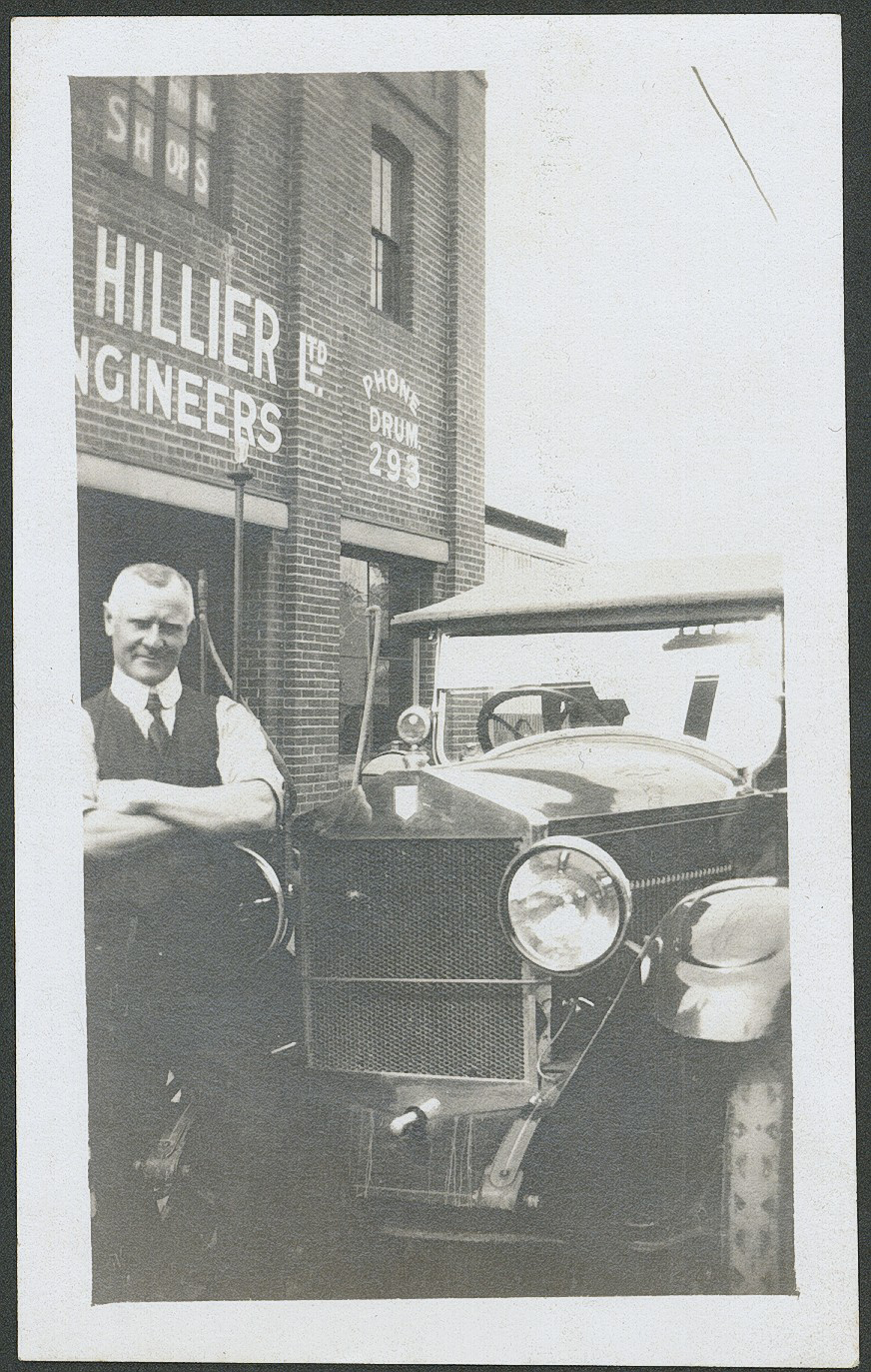

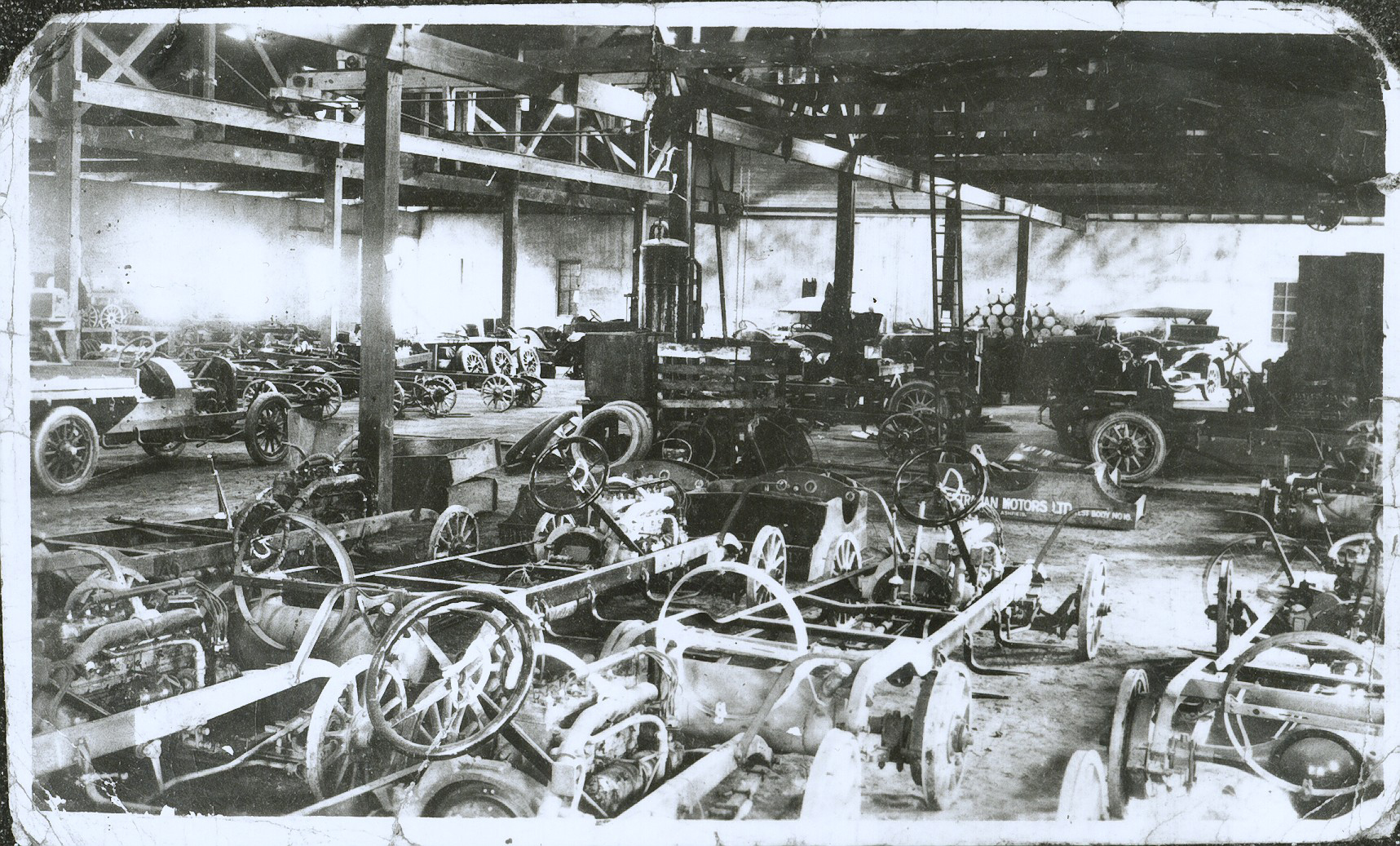

This 1923 Australian Six car is one of only sixteen known survivors of the first serious attempt to develop an Australian automotive industry in the early decades of the twentieth century. On 29 November 1948, Prime Minister Ben Chifley launched Australia's first successfully mass produced car, the Holden, in Melbourne. However, between 1918 and 1925, Australian Motors Ltd had reputedly produced some 500 Australian Six automobiles in Sydney. The entrepreneur behind the venture was Frederick Hugh Gordon who organised for car parts to be bought from America and shipped to Australia for assembly together with parts made locally. The company that began assembly of the Australian Six was F. H. Gordon & Co Ltd, which later merged with Australian Motors Ltd. This company was succeeded by Australian Six Motors Ltd and finally Harkness & Hillier Ltd. The early Australian Six cars were assembled in Sydney at Fred Gordon's workshop and service station in McLauglin Avenue, Rushcutters Bay. Early in 1920 a large factory was established at Parramatta Road, Ashfield, the largest plant of its kind in Australasia containing the latest machinery. It was claimed that every part of the car that could be made locally and economically was made on the premises from Australian materials and by Australian labour, with returned soldiers given preference in the 200-strong workforce. The company's motto was 'Made in Australia, by Australians, for Australia'. The cars built at Ashfield had distinctive 'Rolls Royce' style Grecian-shaped radiators made in Australia. Six different body styles were available, including 8-seat special service cars. These vehicles were popular as hire cars; Rolf's Hire Car Co. offered Sydneysiders a day's motoring from Katoomba station to the Jenolan Caves including a souvenir photograph in the Australian Six taken outside Hartley Court House. The Museum's Australian Six features a four-door, factory-built seven-seat tourer body with fold-down seats, tan paintwork and upholstery. It was built in 1923 and purchased secondhand in 1930 by Leslie (Les) C. McAlpine, a grazier from Windeyer, near Mudgee, New South Wales. He used the car for 22 years and modified it by cutting down the body into a utility. For nine years it was left outside in the weather, but a letter to the 'Modern Motor' magazine in 1963 by a reader alerted the magazine to the car's existence. The historic car was purchased by 'Modern Motor' and subsequently presented to the Museum. During the mid-1960s it was restored under the guidance of Donald Harkness using parts from a spare Australian Six chassis that the Museum had previously acquired from Toukley, New South Wales. Despite this, there are a number of incomplete and missing items. Margaret Simpson, revised 5 December 2007

Loading...

Summary

Object Statement

Automobile, full size, Australian Six, model No. H23, chassis No. 426, four-door tourer body, 6-cylinder, made by Australian Six Motors Ltd, Ashfield, New South Wales, Australia, 1923, used by Leslie McAlpine, Windeyer, New South Wales, Australia, 1930-1952

Physical Description

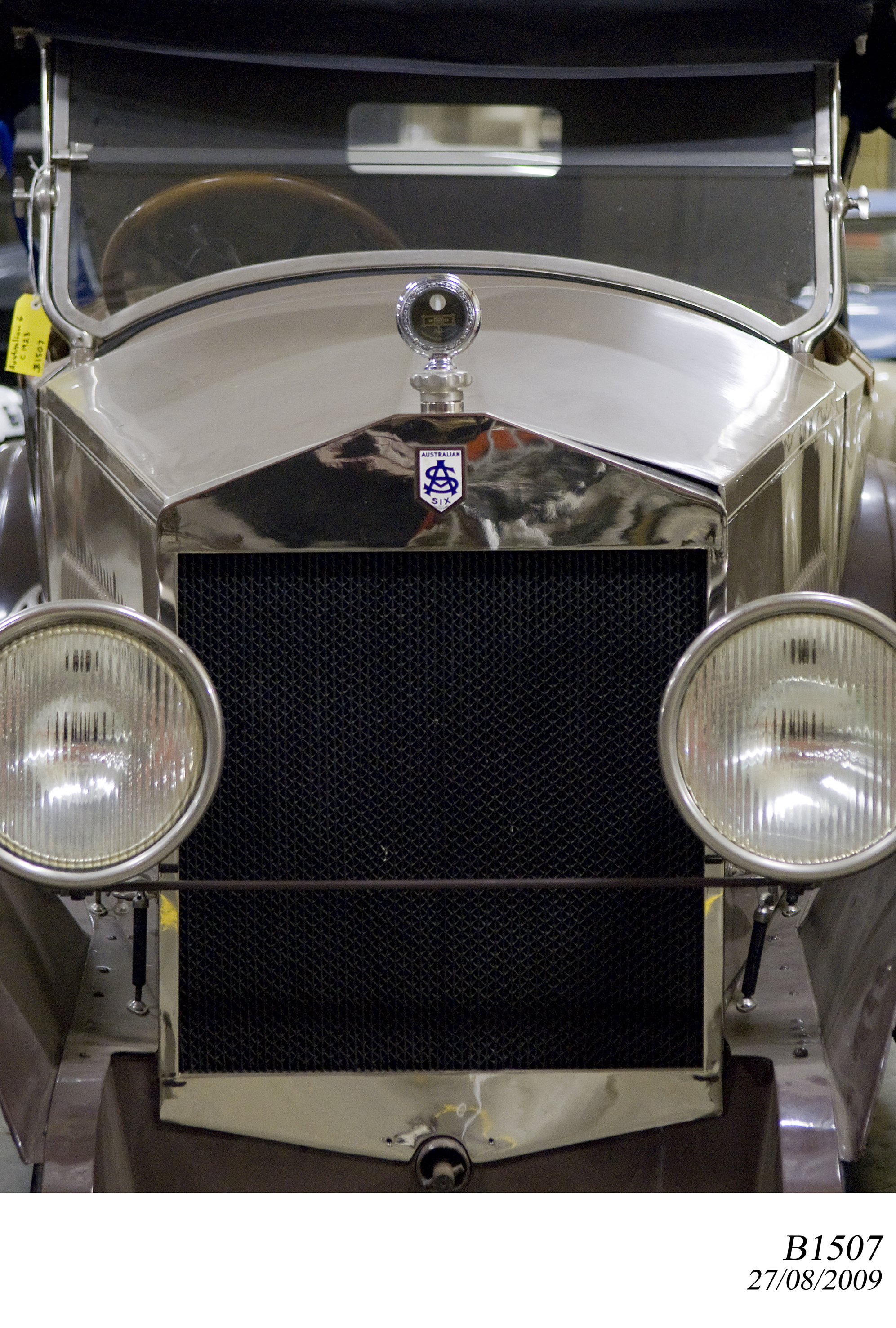

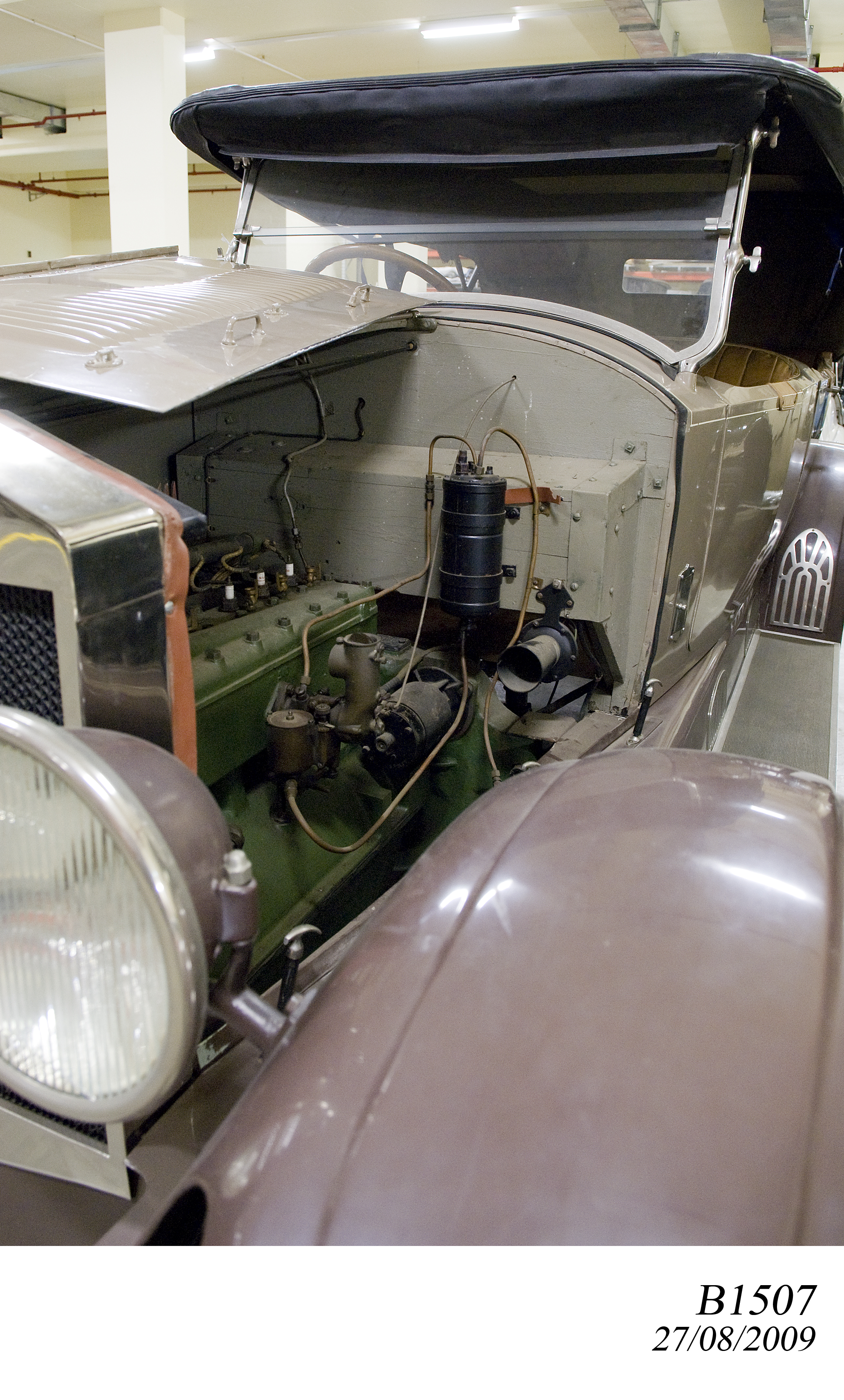

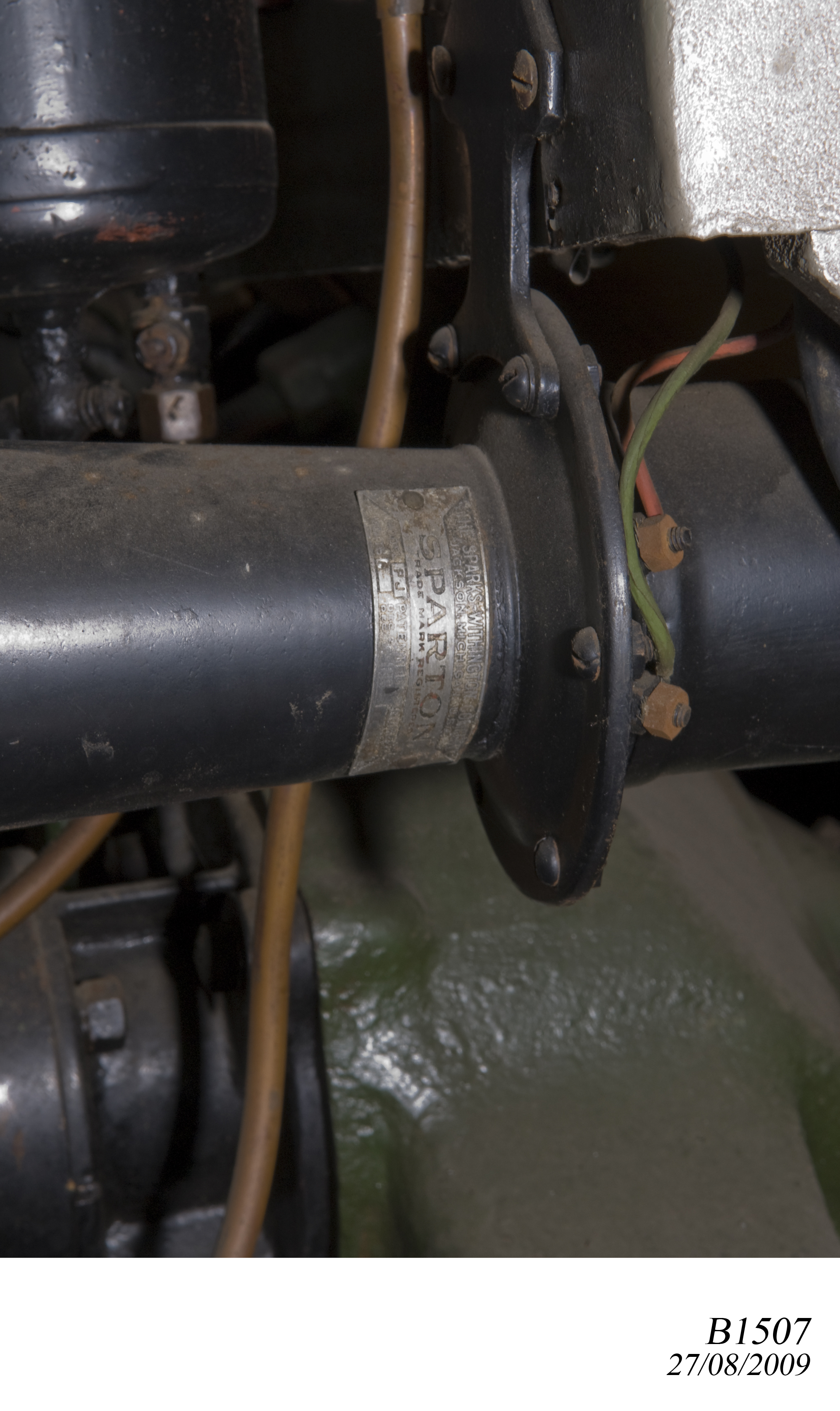

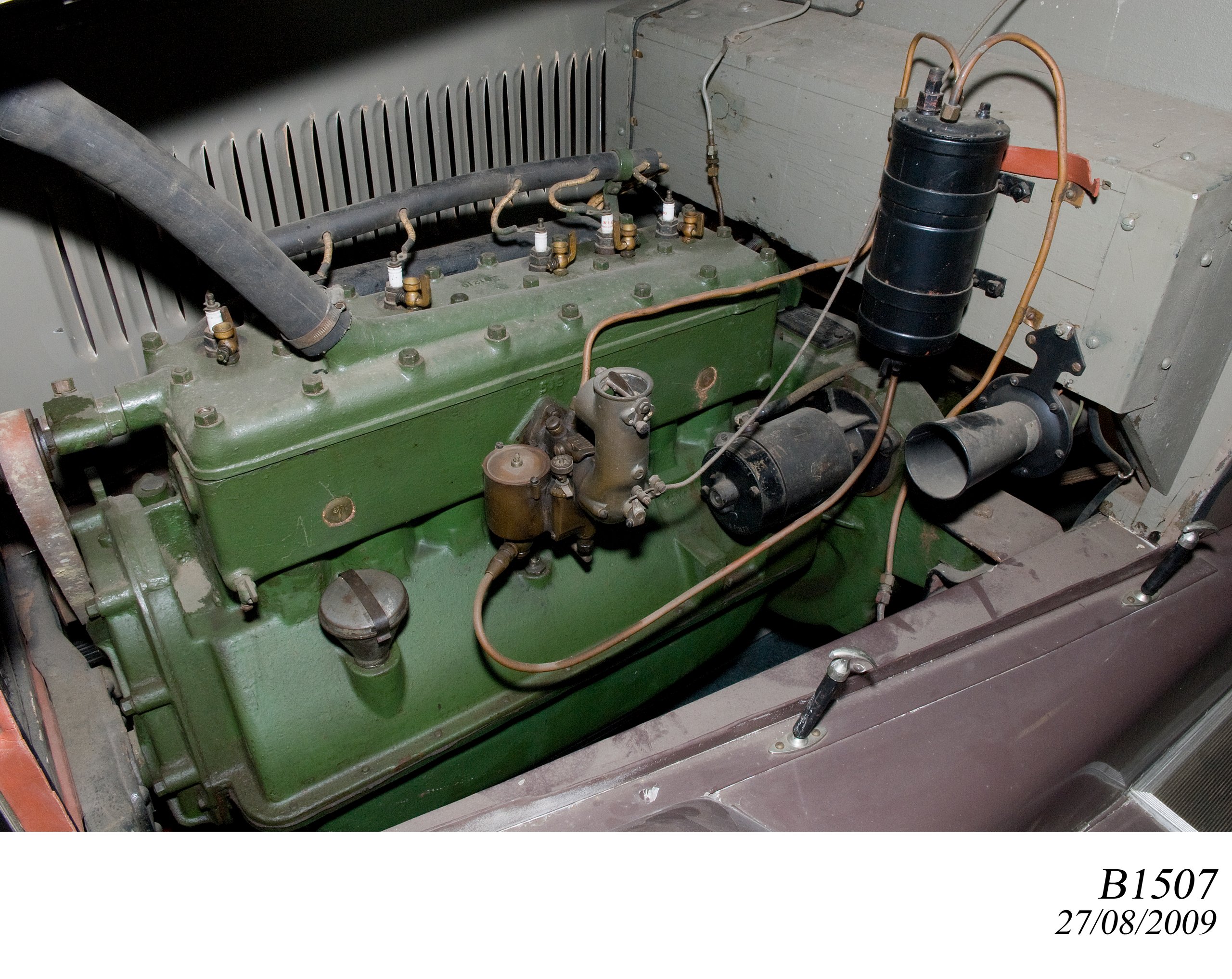

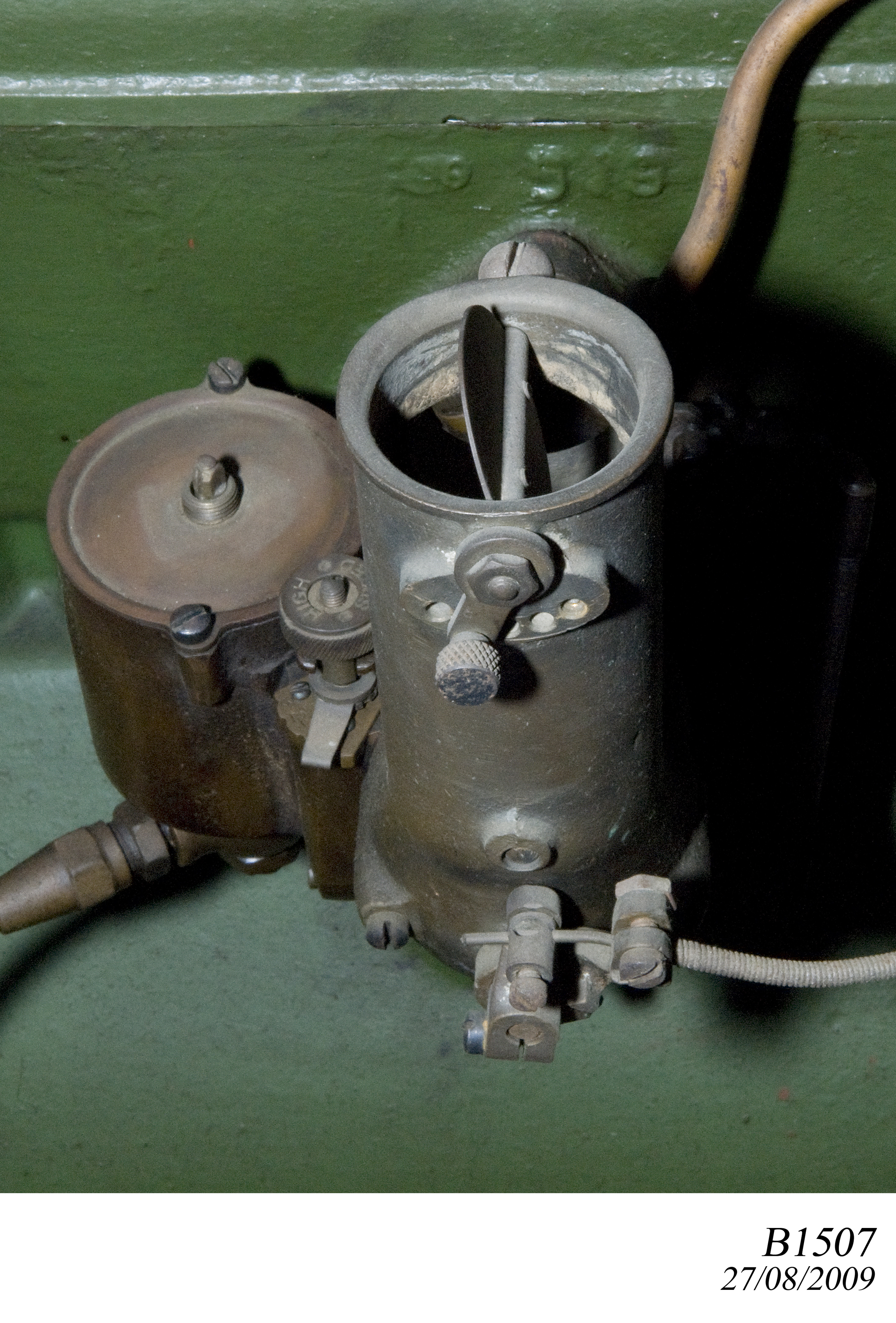

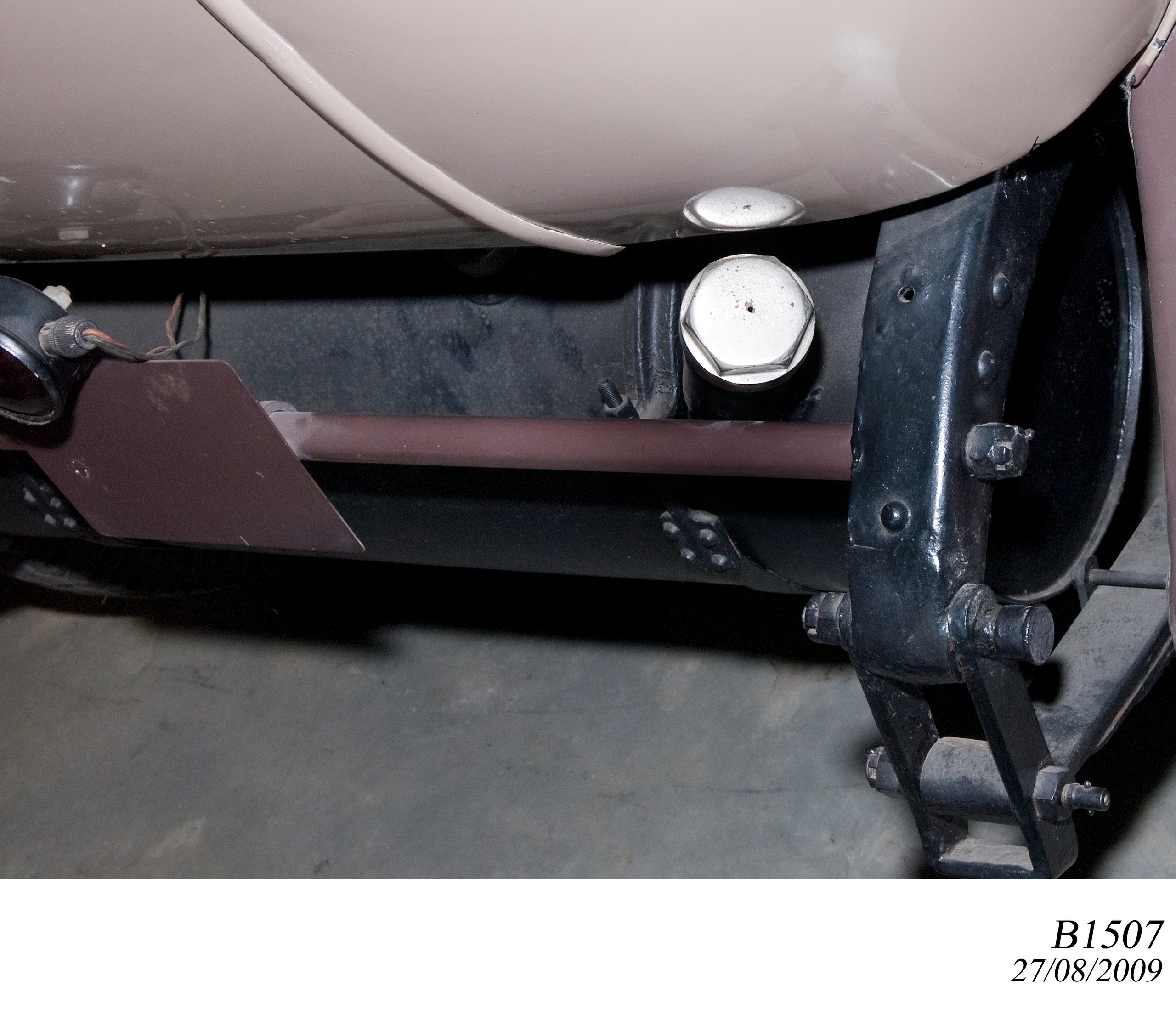

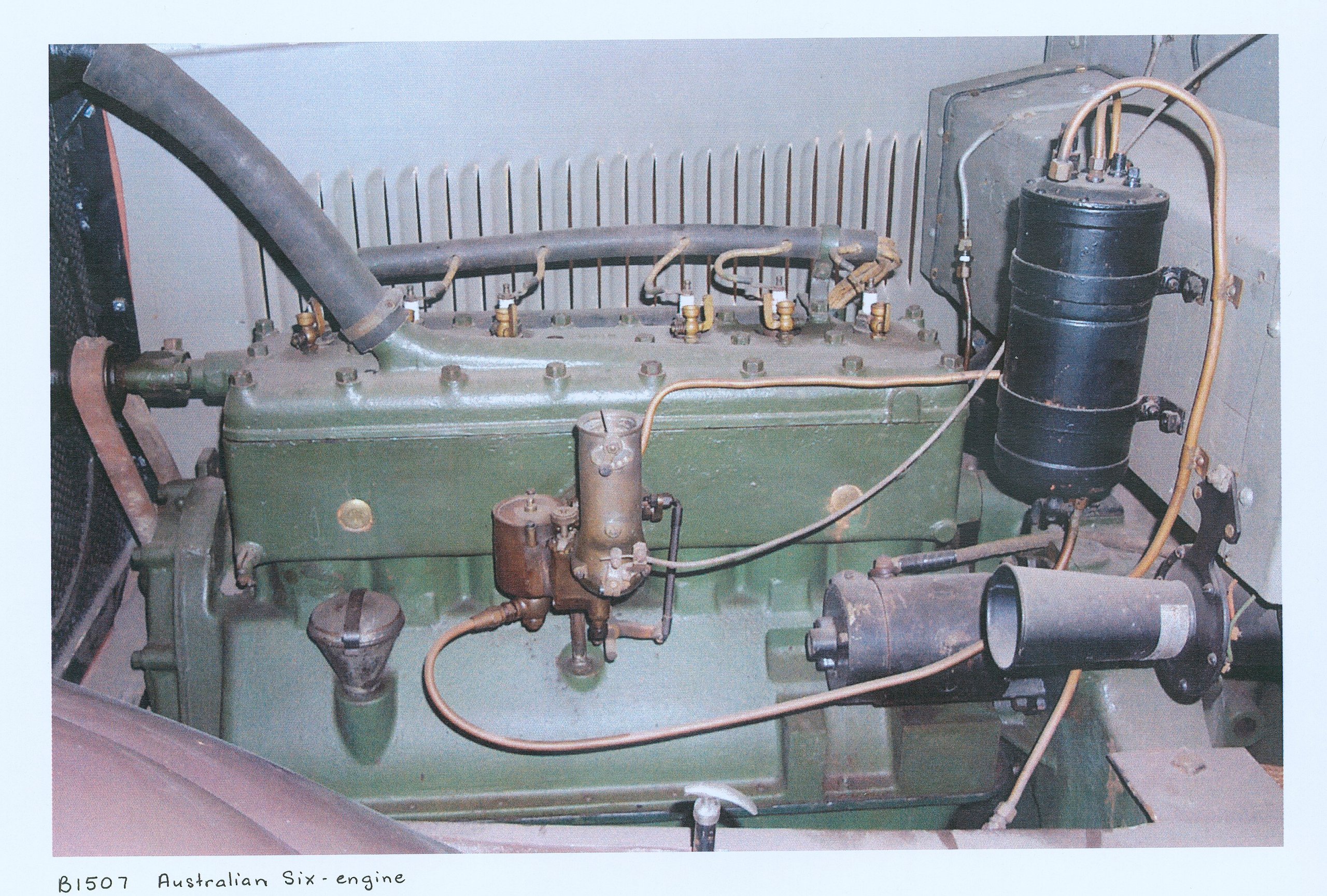

The Australian Six automobile features a four-door, factory-built open tourer body with two fold-down seats, a horizontally split windscreen and folding hood. The paintwork is tan with white lining, while the mudguards are brown. The interior features tan stretch vinyl upholstery. The steel-spoked, wood-rim steering wheel has an ignition advance-retard control mounted in the centre and a hand throttle for starting and slow running. In the centre of the dashboard are various instruments including a National oil pressure gauge, an ignition lock, headlight switch, drum-type speedometer and odometer by Stewart (M-7) including trip meter, a Westinghouse ammeter, choke and dash light. The float-type fuel gauge is incorporated in the tank. On the centre of the floor is a straight gear lever flanked by top button press handbrake. The step-on starter button is also on the floor, but the car can be crank started. The clutch is a multi-plate, dry disc type by Borg and Beck. The engine is a six-cylinder Rutenber with American Bosch magneto ignition. There are expanding and contracting hand and foot brakes acting on the inside and outside of the rear brake drums. Suspension is by semi-elliptical springs front and rear and there is a built-in tyre pump by Kellogg under the floor, driven off the gearbox. The timberwork is sound, but the paintwork on the body is poor and starting to crack. The mudguards are in poor condition and the hood and hood mounts are incorrect. There is a suggestion that the instrument panel has been modified and the upholstery is not of the correct type. The door step plates and spare wheel carrier are missing, while the headlight rims are of round rather than the octagonal shape. The carpet is incomplete and mismatched. The right hand headlight is touching the radiator shell and the nickel-plating on the radiator shell is starting to deteriorate. Specifications Builder: Australian Six Motors Ltd, Parramatta Rd, Ashfield, NSW Chassis No: 426 Model: (primarily) H23 No. 426 (the plate with this information is missing) (Windeyer car) Model: (parts) B2054 (on the dashboard plate) (Toukley car) Engine No: 10J (stamped between engine side plates) Engine casting numbers: 912/9 (on head), 9518 (on left hand side upper cylinder block), 6812-8 (on side plates) Engine: 6-cylinder Rutenber Bore: 3 1/8th in (79.4 mm) Stroke: 5 in (127 mm) Capacity: 230 cu in (3 769 cu cm) Head: 12/09/1919 (car No. 54) Block: 5/09/1919 (car No. 54) Front axle: solid beam type, 5018 258 E20 (May 1920?) Rear axle: Columbia 49:11 ratio, 50014 118 J20 (Oct 1920?) Gearbox: Grant Lees of Cleveland, Ohio, USA, 3-speed, (casting No.4226E) RAC rating: 25.3 hp (20.9 kW) Weight: 30 cwt (1.52 tonnes) Top speed: 40 mph (64 km/h) Carburetors: Stromberg? (LB.1 1838099 or 1888099) Transmission: multi-plate Borg and Beck clutch Suspension: semi-elliptical leaf springs all round Fuel tank capacity: 12 gallons (54.6 litres) Range: 22 m.p.g. (7.8 km/litre) Tyre pressure: 80 p.s.i. (551.6 kPa) (high pressure tyres only) Starter motor: Westinghouse Electric 6 volt Vacuum system for fuel: Sparton Horn: Sparton Windscreen upright: Welsh Bros, Sydney Magneto: American Bosch AT6 model Generator: Westinghouse

DIMENSIONS

Height

2000 mm

Width

1800 mm

PRODUCTION

Notes

Frederick Hugh Gordon was a Sydney engineer and entrepreneur born in 1883, the son of a wealthy grazier. He set up F.H. Gordon & Co. in 1913 and is said to have sold the first Ford, Wolseley and Packard cars in Australia. Gordon was forever searching for new ideas to market and he is attributed with importing the first ready-made suits, noiseless typewriters and fire extinguisher into Australia. His venture into the automotive industry and the development of the Australian Six saw car parts bought from America and shipped to Australia for assembly together with parts made locally. Gordon made regular trips to the United State and while there in 1917 became involved with Louis Chevrolet, the renowned racing car driver and motor engineer who had left the Chevrolet company and was working with American Motors. Gordon obtained from Chevrolet the specifications for an American 'Light Six' car. He then visited all the factories that would supply the various units to go into the car including the engine, gearbox, differential and electrical system and arranged for their importation to Australia. Gordon leased premises at 133-137 Castlereagh Street, Sydney, which were used as a showroom and offices, while the cars were assembled at his workshop and service station at McLauglin Avenue, Rushcuttes Bay. As these premises were quite small, it is thought that only the chassis were assembled there. The chassis comprised components from the American Motor Corporation's American Six Model B with rounded radiators, Salisbury differentials and Grant Lees gearboxes. (Later, Gordon changed to Columbia differentials and Muncie gearboxes, but by the end of late 1921 reverted to Grant Lees gearboxes). The remainder of the work, including building of the car bodies, painting and upholstery, is thought to have been sub-contacted out to other firms. Three of the 5-seat touring car bodies were known to have been built at Millers Motor Body Works at Randwick with mudguards by F. Muller of Crown St, East Sydney. At least ten Australian Six cars were registered by September 1919. The retail price of 495 pounds was claimed in advertisements of the day to be between 200 and 300 pounds cheaper than a comparable imported car. The Australian Six made its debut at Victoria Park Racetrack, Sydney, on 28 June 1919, driven by Robert Mitchell. On 1 July 1919 F.H. Gordon & Co. Ltd launched an advertising campaign designed to attract dealers throughout the Commonwealth. It was obvious that large production numbers required a significantly larger factory and more capital, so on 16 September 1919, Australian Motors Ltd was registered to take over the manufacturing operations of Fred Gordon's company. On 23 December 1919, a site of almost 7 acres on Parramatta Road, Ashfield, was purchased and the largest building of its type in Australia was commenced there to assemble Australian Six automobiles. It was completed in February 1920 and opened three months later. Some 200 workers were employed at the plant at its peak, and agents were established in each state as well as New Zealand. Much was made in declarations that returned servicemen were employed in the plant and that the local content in the car's construction included maple wood from Queensland, metal from BHP Newcastle and leather from Melbourne. Gordon was chairman of the company and remained as the figurehead and spokesman during the rest of 1919 and into 1920. He had very little to do with the construction of the Ashfield plant, nor was he actively involved in the manufacturing activities once the plant went into production. Instead, he managed the sales and marketing departments and also the accounting operations at 133 Castlereagh Street. John Joshua Hughes was the Managing Director of the company and David Buchanan Martin was Director and Plant Manager. The cars' leaf springs were originally imported but later made at Petersham. The seating upholstery was done in buttonless, pleated full-hide leather. Six different body styles were available, namely: the 3-seat straight seat, 3-seat clover leaf, 5-seat fixed front seat, 5-seat sliding front seat, 7-seat tourer, and an 8-seat special service car (charabanc). Both standard and de-luxe versions of the 5-seat and 7-seat touring cars were available. Standard artillery wheels made at the factory were fitted but by 1922 wire or disc wheels were an optional extra. Despite all the positive and promising advertising, the firm had quality control problems. Many of the cars were returned to the factory, and the Rutenber engines had to be dismantled and rebuilt including machining of the rough engine block and fitting higher grade bearings. The stories of the engine troubles were poor publicity for the manufacturers but once rectified the cars were as sturdy and reliable as had been promised: a car made for Australian conditions. More and more Australian firms came in as suppliers until the car was said to have a local content of 60 or 70 percent. In effect, this appears to be a publicity claim as all the mechanical components were still imported except for the locally-built car bodies, some small body castings, radiators, fuel tanks and other small components. On 23 March 1921 Australian Six Motors Sales Ltd was formed to take over the sales and distribution of the troubled manufacturing arm, Australian Motors Ltd, as well as to introduce new capital via the Overseas Sales Agency (Australia) Ltd, trading as the Savage Tyre & Rubber Co. Within six weeks of starting this new venture, David Martin, who was director of this company as well as Australian Motors Ltd, died suddenly of influenza on 18 April 1921, and the New Zealand parent company, Overseas Sales Agency (Australia) Ltd, collapsed. Consequently the newly re-organised conglomerate, Australian Six Motor Sales Ltd, folded in July 1921. It appears the company continued to trade throughout 1922 and assets were finally sold to a new company, Australian Six Motors Ltd, which formed on 23 February 1923 with S. Diamond, J. Diamond and S. Kemelfield as directors. Production at Ashfield continued until the end of 1923. By this time Australian Six Motors Ltd had been purchased by the motor engineers, Harkness & Hillier. Donald Harkness had been selling Australia Six cars on commission while traveling interstate on business for his own firm, as well as running Australian Six cars in his taxi fleet. Production of the Australian Six moved to a new site on Parramatta Road, Five Dock, bounded by Spencer Lane and Spencer Street. Harkness & Hillier invested considerable capital in this new facility. Unfortunately, sales did not increase and less expensive, smaller imported cars such as the Model T Ford flooded the market. The last Australian Six was built at Five Dock in 1925. The Ashfield factory was purchased by the motor body builder, Redwood Brown & Co. Ltd, which later obtained the agency for Dodge cars. The building became a massive assembly plant known as Dodge Park while from 1931 to the early 1990s some part of the site accommodated Amalgamated Wireless (Australasia) Limited (AWA). Some of the other surviving Australian Six cars include an early 1918 prototype owned by George Gilltrap and a white 1924 or early 1925 roadster owned by John Cook. Another tourer is held at the York Motor Museum in Western Australia, restored by Simon Kelleher, Fred Gordon's grandson, and another was purchased at auction at Foster, New South Wales, by Immanuel Hansen. A collection of Australian Six components was also presented to the National Motor Museum, Birdwood Mill, South Australia, from the Powerhouse Museum.

HISTORY

Notes

The Museum's Australian Six was built in 1923 and purchased second hand in 1930 by Leslie (Les) C. McAlpin, who had a property at Windeyer, near Mudgee, in the Central West of New South Wales. He used the car for 22 years with the registration number EA 033 and during that time undertook some major modifications to the original touring car body by converting it into a farm utility. He had the hood shortened and a tailgate cut in the back. He replaced the pistons with a set scavenged from another Australian Six and shaped the original pressed-fibre timing gear from aluminium that he cast himself by melting down old kettles and saucepans. The car gave good service but was last used in 1953. For nine years it was left outside in the weather, but a letter to the 'Modern Motor' magazine in 1963 by a reader, R.C. Murray from nearby Pyramul, alerted the magazine's editor to the car's existence 'mouldering on blocks' on Mr McAlpin's property. While test driving the just released EJ Holden at that time 'Modern Motor' staff drove to Windeyer to inspect the significant car and purchased it from McAlpin. A film of the Holden test drive together with the Australian Six was featured on ATN television (Channel 7) that night. The next day, Norman Harwood, Assistant Keeper of Engineering at the Museum, contacted 'Modern Motor' with great interest as the Museum, together with Donald Harkness of Harkness & Hillier motor traders, who had been involved in the manufacture of the Australian Six, had been looking for an example of the vehicle for the Museum's collection for years. 'Modern Motor' Magazine of Kent House, 88 Liverpool Street, Sydney, presented the car to the Museum in 1963 through its Director and Editor, J.M. Feldman. When the car was acquired by the Museum it was in a poor condition. By the mid-1960s it was decided to enter the car in the 1970 International Motor Rally, so a full restoration was planned. Museum staff, assisted by Donald Harkness, completely dismantled all the mechanical components of the car and inspected them. As there was a great deal of wear evident, it was decided to dismantle the spare Australian Six chassis (object number B2054) that the Museum had acquired from Toukley on the NSW Central Coast to see whether these mechanical components were any better, but these were also found to be badly worn. As there was no money available to undertake a major overhaul of the car, it was decided to use the best parts from both cars to make a composite car. The students of the Sydney Technical College Body Building School undertook the bodywork and upholstery restoration. Despite the restoration, the car never competed in the rally.

SOURCE

Credit Line

Gift of 'Modern Motor' magazine, 1963

Acquisition Date

20 March 1963

Copyright for the above image is held by the Powerhouse and may be subject to third-party copyright restrictions. Please submit an Image Licensing Enquiry for information regarding reproduction, copyright and fees. Text is released under Attribution-Non Commercial-No Derivative licence.

Image Licensing Enquiry

Object Enquiry