Steam traction engine

Object No. B1498

Traction engines may be defined as mobile (wheeled) steam engines whose purpose is to pull loads on roadways and in this most basic form are also called "road locomotives", an indication of their evolution from the railway locomotive. Traction engines originated in England in about 1860, after some experimental work during the preceding decade by builders of portable steam engines. For the next 60 years, several companies including John Fowler of Leeds, Charles Burrell of Thetford and Aveling & Porter of Rochester dominated the manufacture of traction engines. J & H McLaren were also located in Leeds and their factory shared a common boundary with the premises of the John Fowler works. John and Henry McLaren were Scottish blacksmiths whose company produced more general purpose engines than any other type. However, they also built road construction military equipment. The simple and practical design for which McLaren traction engines became known was inspired by one of McLaren's engineers who had experience in working with early forms of steam propulsion used by the Royal Navy. An example was in the easy adjustment and repair of their bearings. The English cities of Leeds and Lincoln and the agricultural regions of East Anglia and Hampshire were the chief locations where traction engines were manufactured. They were designed and built in many forms including general purpose traction engines, steam rollers, showman's engines, road locomotives, steam plough engines and light steam tractors. General purpose traction engines had a nominal power of 5 to 8nhp and usually had a single cylinder, although major manufacturers such as John Fowler also built a compound (or two-cylinder) version. The first Fowler compound was built in 1881, an 8nhp model with slide valves (which regulate the flow of steam into and out of the cylinders) mounted between the cylinders although they were later to be located on top of the cylinders, as on the engine under consideration. To undertake the range of heavy work they do, the rear wheels of traction engines need to be driven through at least two gears and sometimes, for long distance haulage work where faster speeds are required, three gears. The general purpose traction engines, of which the Museum's McLaren traction engine is an example, was essentially an agricultural engine and represented the type in its basic form. Its main job was threshing, although in Australia they were commonly used for carting wool, wheat and timber, for land clearing, for direct ploughing, to drive chaff cutters and pumps and to operate machinery in sawmills. McLaren ploughing engines were also used in pairs with a chain for land clearing. The Museum's McLaren 7nhp engine was manufactured in 1904 and assigned the builder's number 815. Little is known of its history but it may have been originally sold to the company from whom the Museum was to purchase the engine in 1962, George Fish Pty Ltd, cnr. Bentick and Russell Streets, Bathurst, New South Wales. The original McLaren records show that it was designated a "strawburner" engine, meaning that straw was to be used as a source of fuel. This would usually involve the purchase of a device that enabled the straw to be fed into the firebox, although no evidence of this survives with the engine. Steam traction engines eventually gave way to tractors powered by internal combustion engines, initially developed during the First World War. A large surplus became available during the 1920s and as a result there was a marked decline in orders for traction engines in all their forms, most of which were still manufactured in England. By 1930, the general purpose traction engine era had come to an end. After the Great Depression of the early 1930s, a period of consolidation followed. Several companies ceased trading while others such as Clayton & Shuttleworth, Ruston & Hornsby and J & H McLaren diversified into other aspects of production.

Loading...

Summary

Object Statement

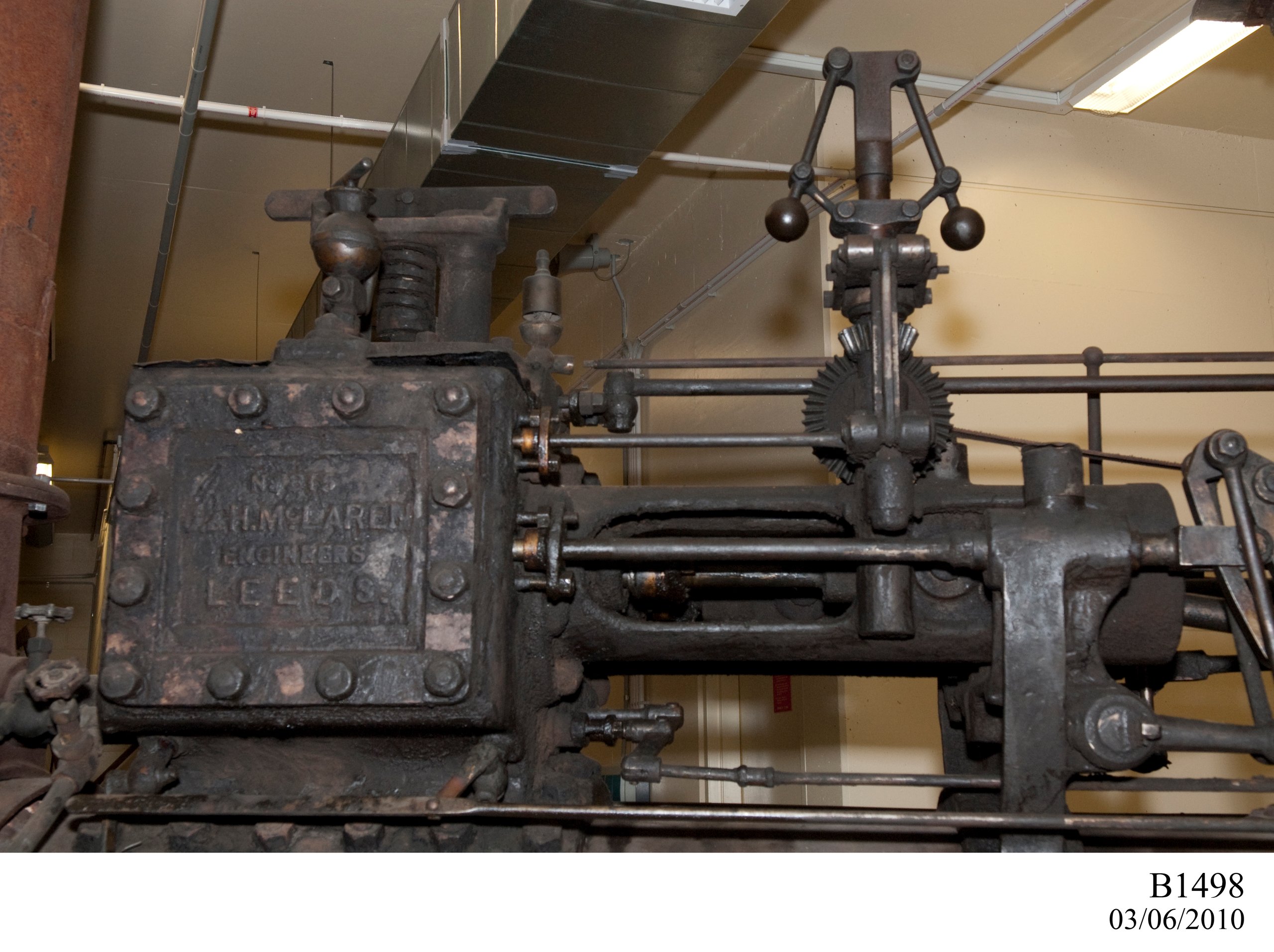

Steam traction engine, general purpose, two speed, compound, no 815, 7nhp, metal / wood, made by J & H McLaren, Leeds, England, 1904

Physical Description

Two speed McLaren steam traction engine, double crank compound (two-speed), unsprung and fitted with a belly tank, outside valve gear, slide valves, Stephenson link motion, spoked flywheel, roof, straked road wheels. Unrestored, as used condition. The livery of the engine comprises black with brown detail and yellow and red linework. Some of the original black paint and traces of the linework remain.

DIMENSIONS

Height

3050 mm

Width

2150 mm

PRODUCTION

Notes

This steam traction engine was made by J & H McLaren Ltd in Leeds, England in 1904.

HISTORY

Notes

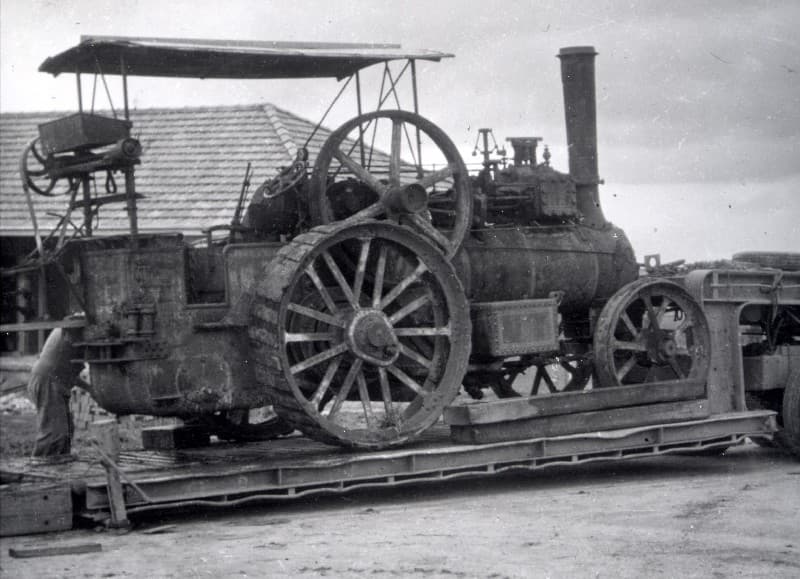

Traction engines may be defined as mobile (wheeled) steam engines whose purpose is to pull loads on roadways and in this most basic form are also called "road locomotives", an indication of their evolution from the railway locomotive. Traction engines originated in England in about 1860, after some experimental work during the preceding decade by builders of portable steam engines. For the next 60 years, several companies including John Fowler of Leeds, Charles Burrell of Thetford and Aveling & Porter of Rochester dominated the manufacture of traction engines. J & H McLaren were also located in Leeds and their factory shared a common boundary with the premises of the John Fowler works. John and Henry McLaren were Scottish blacksmiths whose company produced more general purpose engines than any other type. However, they also built road construction military equipment. The simple and practical design for which McLaren traction engines became known was inspired by one of McLaren's engineers who had experience in working with early forms of steam propulsion used by the Royal Navy. An example was in the easy adjustment and repair of their bearings. The English cities of Leeds and Lincoln and the agricultural regions of East Anglia and Hampshire were the chief locations where traction engines were manufactured. They were designed and built in many forms including general purpose traction engines, steam rollers, showman's engines, road locomotives, steam plough engines and light steam tractors. General purpose traction engines had a nominal power of 5 to 8nhp and usually had a single cylinder, although major manufacturers such as John Fowler also built a compound (or two-cylinder) version. The first Fowler compound was built in 1881, an 8nhp model with slide valves (which regulate the flow of steam into and out of the cylinders) mounted between the cylinders although they were later to be located on top of the cylinders, as on the engine under consideration. Traveling speeds of traction engines were governed by the number of gears. For traction engines, this was generally two, whereas road locomotives generally had three gears to allow the engine to travel at a higher speed for hauling on roads. The general purpose traction engines, of which the Museum's McLaren traction engine is an example, was essentially an agricultural engine and represented the type in its basic form. Its main job was threshing, although in Australia they were commonly used for carting wool, wheat and timber, for land clearing, for direct ploughing, to drive chaff cutters and pumps and to operate machinery in sawmills. McLaren ploughing engines were also used in pairs with a chain for land clearing. Steam traction engines eventually gave way to tractors powered by internal combustion engines, initially developed during the First World War. A large surplus became available during the 1920s and as a result there was a marked decline in orders for traction engines in all their forms, most of which were still manufactured in England. By 1930, the general purpose traction engine era had come to an end. After the Great Depression of the early 1930s, a period of consolidation followed. Several companies ceased trading while others such as Clayton & Shuttleworth, Ruston & Hornsby and J & H McLaren diversified into other aspects of production. McLaren engines imported into Australia were assigned to a wide range of agricultural applications, including the development of the Murray River irrigation colonies in Victoria and South Australia (see below) and preparation of fields for sugar cane production. McLaren road locomotives Nos 1330 to 1333 of 10 nominal horse power rating were used for contract work for the South Australian Government. They were also used in Government contracting for land clearing and the construction of Canberra and for haulage relating to the construction of the Cotter Dam. In the 1880s and 1890s, the Victorian and South Australian governments employed the Canadian Chaffey Brothers to set up irrigation colonies on the Murray River. McLaren ploughing engines were used to clear the land and McLaren traction engines were used for direct ploughing the fields for the dried fruit in the irrigation colonies at Mildura, Victoria and Renmark, South Australia and for the fruit for the orchards throughout the Mildura area. The engines imported to Australia ranged from small rotary ploughs of less than one nhp to large ploughing rotary engines of forty nhp. McLaren also exported 8 nhp superheated traction engines that were used in Victoria and southern New South Wales. Examples survive in Echuca, Victoria and Lithgow, NSW. McLaren road locomotives of 10nhp were used for haulage in the Sydney region, such as in the Wollondilly area. The engines also were used in timber haulage by individual timber companies. Property owners used McLaren traction engines for ploughing, for chaff cutting and general use before the introduction of the internal combustion engine to farming work. An eight nhp McLaren engine is known to have been used as late as the mid 1990s in Queensland for chaff cutting and threshing. The Museum's McLaren 7nhp engine was manufactured in 1904 and assigned the builder's number 815. Little is known of its history but it may have been originally sold to the company from whom the Museum was to purchase the engine in 1962, George Fish Pty Ltd, cnr. Bentick and Russell Streets, Bathurst, New South Wales. The original McLaren records show that it was designated a "strawburner" engine, meaning that straw was to be used as a source of fuel. This would usually involve the purchase of a device that enabled the straw to be fed into the firebox, although no evidence of this survives with the engine. At the time of acquisition by the Museum from the vendor, the engine was located on a site at Kelso presumably owned by the vendor, a few kilometres east of Bathurst, from where it was loaded onto a low loader. According to the late Mr Norman Harwood, the former curator of Transport and Engineering and Curator Emeritus of the Museum, the operation was very time consuming and bad weather was setting in. The truck driver was obliged to stay at a local motel overnight during which a snow storm covered the region. At first light, the driver set off for Sydney with the path of the low loader shown by its multiple tyre tracks along the snow-covered Great Western Highway.

SOURCE

Credit Line

Purchased 1962

Acquisition Date

11 October 1962

Copyright for the above image is held by the Powerhouse and may be subject to third-party copyright restrictions. Please submit an Image Licensing Enquiry for information regarding reproduction, copyright and fees. Text is released under Attribution-Non Commercial-No Derivative licence.

Image Licensing Enquiry

Object Enquiry