Sheep shearing machine made by Wolseley

Object No. 90/137

This is a three-stand shearing machine made between 1890 and 1910 by the Wolseley Sheep-Shearing Machine Company Pty Ltd. Frederick York Wolseley was the pioneer of standard shearing sets which were cheap and mass produced. The introduction of mecanised shearing in 1887 caused the demise of hand shearing of sheep which had been practiced for thousands of years. The importance of the introduction of the shearing machine meant that more wool could be removed from the sheep more quickly and with less skill than a hand shearer. It used to take about 2 years of training and experience on the job to become a good hand shearer but with a shearing machine almost anyone could learn to be a skilled shearer in a few days. There were three types of shearing machines: those driven from shafting, independent electric motors or portable plants. The most popular in Australia and New Zealand were the shaft-driven ones set up in shearing sheds and involved the shaft belt-driven from a motor. The shaft was mounted on roller bearings set in wall brackets and run at 600 to 700 rpm. The drive for each handpiece was flexible and was taken from the shaft by a friction wheel and friction cone. Shearing machines operated on the same principle as the mower cutter bar. A cutter reciprocated at high speed between the comb and the forks of the shear head. The shearing surfaces were at the lower surface and the upper surface was the comb. As Australian flock sizes increased dramatically during the second half of the 19th century, there was a need to develop mechanised shearing. Its introduction was hampered by the need to find a cutting system which would not clog with wool, would remain efficient, and have a flexible power transmission which would not restrict the movement of the shearer. The world's first patent for a shearing machine was granted to a Melbourne compositor, J.A.B. Higham, in 1868, inspired by a British horse clipping machine but it has the drawback of being fixed to one spot. In 1870 J.A.E. Gwynne patented a flexible drive shaft which meant the shearer wasn't restricted. The first practical commercial machine was invented in 1872 by Frederick York Wolseley (1837-1899), a NSW squatter from near Walgett, and Robert Savage. It was patented in 1877 but took until 1885 to become as efficient and more reliable than hand shears. Wolseley and Savage' s invention comprised a reciprocating three-tooth cutter driven by an endless rope from an overhead shaft. Launched in 1886, the sheep-shearing machines could cut more wool from the sheep in a single piece than by expertly blade-shorn sheep, were easier to use and less likely to cut the sheep by only needing to guide the handpiece through the wool. They also greatly reduced muscular strain on the shearer, not having to press the blades together. Trials and shearing demonstrations were held at shearing heads in the eastern Australian States and New Zealand, and Wolseley set up a company to manufacture the machine in Melbourne. The first complete flock of sheep to be machine-shorn was in 1888 at Sir Samuel McCaughey's "Dunlop" station at Louth in New South Wales. There was hostility from some shearers who felt their jobs were threatened. Also, some graziers were reluctant to outlay the initial installation costs of the machines especially during the depression and drought of the early 1890s. Further improvements to the Wolseley machine's overhead gear, with an adjustable bracket which became the famous Wolseley No. 4 bracket, were made by a young Herbert Austin (1866-1941). Steam, and later internal combustion engines, powered sheep shearing machinery. The first electric-powered shearing machine was exhibited in Sydney in and introduced commercially in 1909 as the Falkiner-Boll. In the days of hand shearing, the shed was a quiet place with only the snip of the blades, but with the advent of the shearing machine the shed was full of noise from the engine, overhead shafting and the whirring of hand-pieces. The uptake of the shearing machine in sheds around Australia was very quick and by 1900 hand shearing was the exception rather than the rule. Margaret Simpson, Curator March 2016

Loading...

Summary

Object Statement

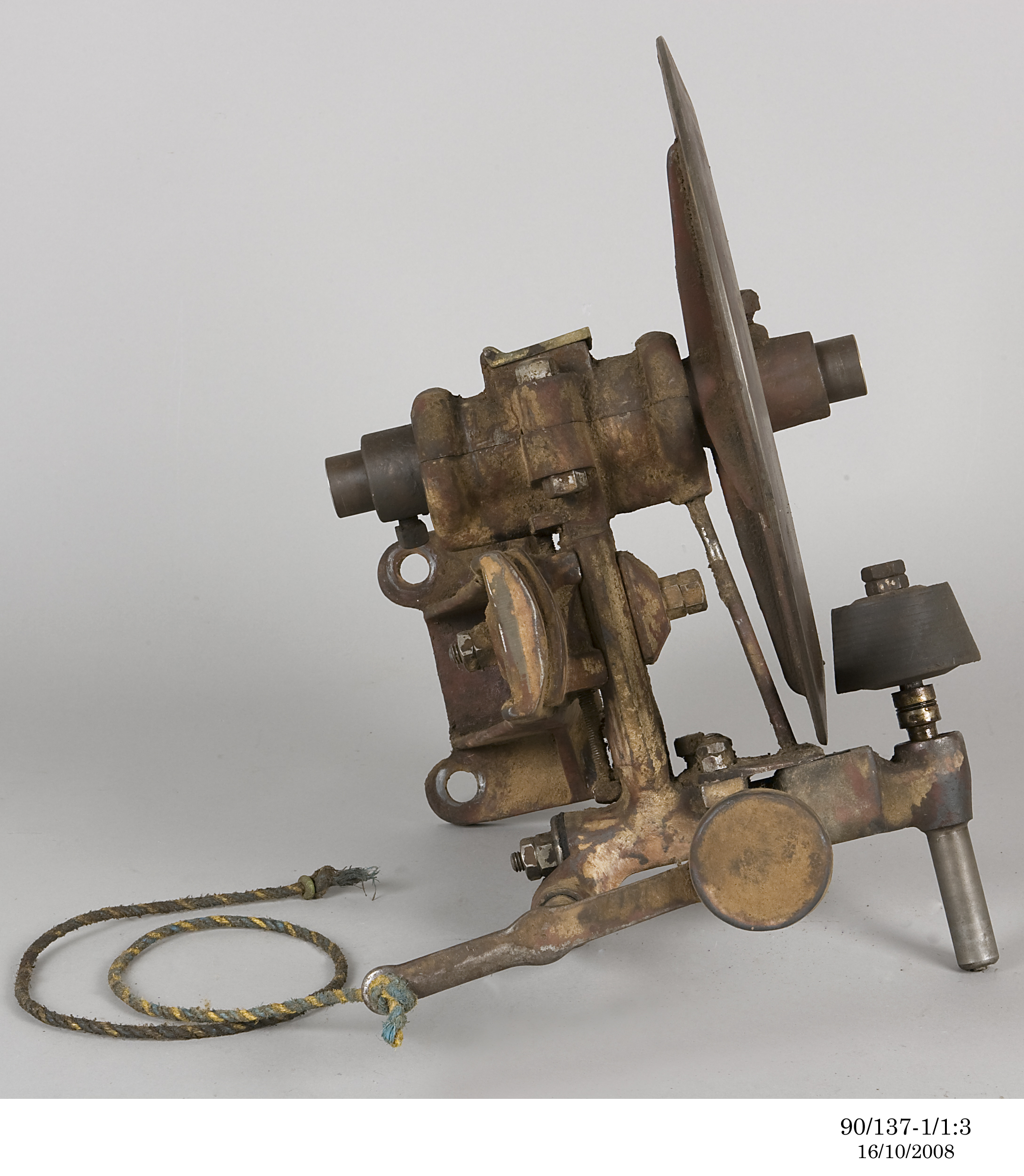

Sheep shearing machine, three stand, metal / [leather], made by Wolseley Sheep-Shearing Machine Company Pty Ltd, Witton, Birmingham, England / Melbourne, Victoria, Australia, 1890-1910, used at Bone-Bone Station, north of Dubbo, New South Wales, Australia, until 1989

Physical Description

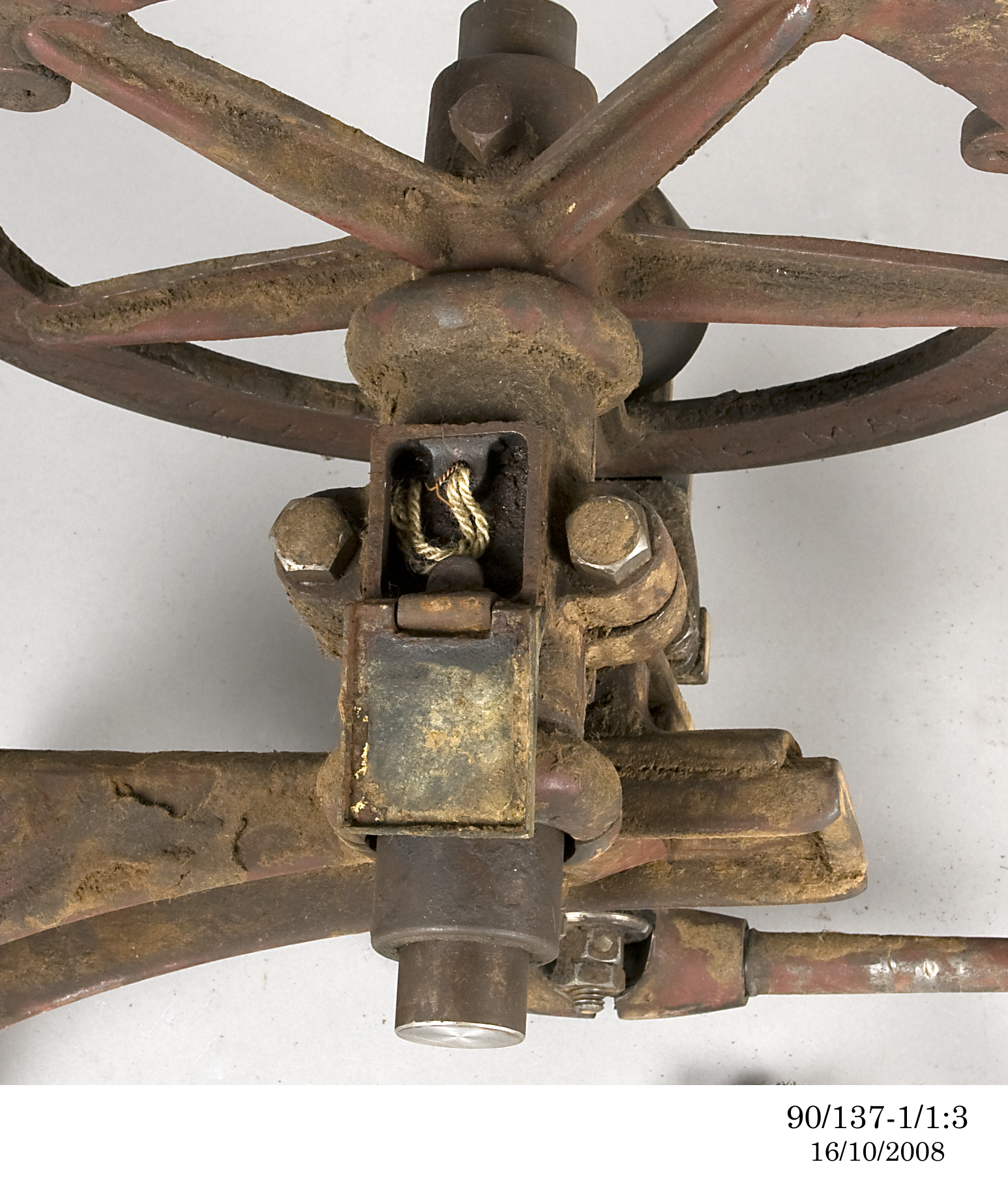

Sheep shearing machine, three stand, metal / [leather], made by Wolseley Sheep-Shearing Machine Company Pty Ltd, Witton, Birmingham, England / Melbourne, Victoria, Australia, 1890-1910, used at Bone-Bone Station, north of Dubbo, New South Wales, Australia, until 1989 The three-stand shearing set consists of a horizontal shaft supported by three brackets, with three metal flywheels coupled to three drive mechanisms. These activate counter weight release so that the down pieces can work from the flywheel. The whole set is powered by a small Lister petrol engine. All components are metal and in good condition. They were last used in 1989.

PRODUCTION

Notes

The Wolseley Sheep-Shearing Machine Co. Ltd was established in 1887 in Melbourne, Victoria, by Frederick York Wolseley to manufacture sheep shearing machines invented by Wolseley and others. In 1889 Wolseley went to England and set up the Wolseley Sheep-Shearing Machine Co. Ltd in Witton, Birmingham, and engaged Herbert (later Baron) Austin as foreman in his workshops at Goldsborough, Mort & Co. Ltd in Melbourne. Austin improved the overhead gear and in 1893 went to Birmingham as production manager. Wolseley resigned as managing director in 1894 and died in 1899. In 1901 Vickers Sons & Maxim Ltd took over the machine tool and motor side of the Wolseley works trading as the Wolseley Tool & Motor Car Co. Ltd. From 1905 Wolseley's started manufacturing cream separators and power units (vertical, 4-stroke oil engines) to run them were produced from 1909. The engines were also used to power sheep shearing machines and could power six handpieces. During the 1950s and early 1960s Wolseley's produced the American "Merry Tiller" rotary cultivator under licence from the Merry Tiller Manufacturing Co., of Seattle, Washington, USA. The firm became Wolseley Engineering Ltd in 1958 after its merger with Geo. H. Hughes forming the Wolseley-Hughes Group which was joined in 1963 by H.C. Webb and became Wolseley-Webb.

HISTORY

Notes

This shearing set was installed in the 1890s at Bone-Bone Station, near Mendooran north of Dubbo, NSW. It remained in constant use with very few modifications until 1989 when it was donated to the museum. Powered shearing stands replaced hand shearing within a few years after being introduced in NSW. During the 1830s squatters in Australia illegally took their flocks to the unsettled districts and established runs of hundreds of kilometres. At first shepherds tended the flocks but after they left for the gold rushes in the 1850s, fences had to be used which in turn allowed for selective breeding, disease control and improved the quantity and quality of wool. In times of economic depression or drought, squatters received some income by boiling down their sheep for tallow. During the 19th century, when roads were poor, transporting the bulky wool to coastal ports was very expensive. Wool scours washed and reduced the weight of the wool and presses were devised to compress it into tight bales. Wool travelled in drays, wagons, paddle steamers and railways to reach the city wool stores before shipment on clipper ships to England. Squatters worked hard to maintain their flocks and wool in good condition for the lucrative English woollen mills. Washing the sheep before shearing helped clean the wool and remove burrs. Sheep were shorn in specially-designed shearing sheds. Before machine shearing was introduced into shearing sheds in 1888, hand shears were used. From 1918 solder settlements and other factors say the subdivision of large sheep holdings into smaller ones. Where previously there had been large shearing sheds with 20 shearing stands or more, powered by a steam engine, during the first decades of the twentieth century small wool sheds with four to six stands became the most common.

SOURCE

Credit Line

Gift of Mr and Mrs John Estens, 1990

Acquisition Date

27 February 1990

Copyright for the above image is held by the Powerhouse and may be subject to third-party copyright restrictions. Please submit an Image Licensing Enquiry for information regarding reproduction, copyright and fees. Text is released under Attribution-Non Commercial-No Derivative licence.

Image Licensing Enquiry

Object Enquiry